- Login or Register

No account yet? Sign up

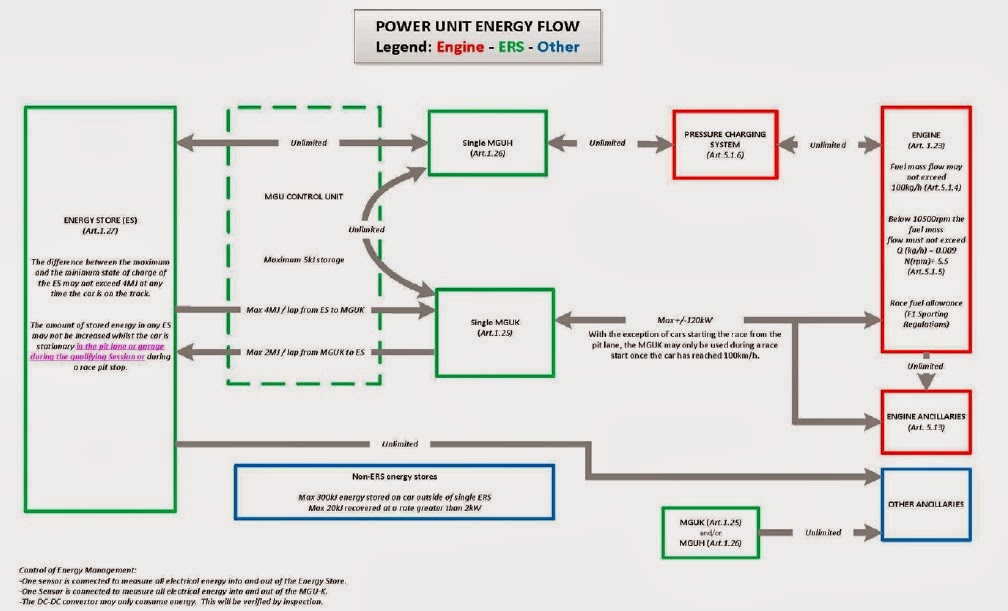

More interesting is to ponder what kind of materials are used in the windings, surely there are better conductors of electricity than copper, and seeing as how it's essentially a spending free-for-all, I don't know why any top team would settle for mere copper windings.Per wrote:Following up on the discussion in the Honda PU topic on MGU-H harvesting energy that is provided directly to the MGU-K, an energy flow which is unlimited.

Would it be technically possible and legal to do it the other way around as well, by any significant amount? The MGU-K is allowed to harvest 2MJ per lap straight into the ES. But there is no limit for energy going from MGU-K to MGU-H. So if you have filled up the 2MJ for that lap, you could use the MGU-K to boost the MGU-H during braking.

Of course this would only make sense if the MGU-H can do something useful with that energy. I don't know a lot about electric motors so my question is: would it be possible to have an MGU-H with two windings with separate control, one 'connected' to the ES and the other to the MGU-K? If so, would it be possible to have one winding on generator mode (using energy coming from MGU-K) and the other on harvesting mode to store this energy into the ES?

If this would work and it is legal, you could potentially recover more kinetic energy than 2 MJ per lap.

I'm sorry if this idea sounds ridiculous, I just don't have enough knowledge about electric motors to know any better.

I don't know it it would be worth it, but I like the idea of having the KERS store extra energy via the MGUH.Per wrote:Following up on the discussion in the Honda PU topic on MGU-H harvesting energy that is provided directly to the MGU-K, an energy flow which is unlimited.

Would it be technically possible and legal to do it the other way around as well, by any significant amount? The MGU-K is allowed to harvest 2MJ per lap straight into the ES. But there is no limit for energy going from MGU-K to MGU-H. So if you have filled up the 2MJ for that lap, you could use the MGU-K to boost the MGU-H during braking.

Of course this would only make sense if the MGU-H can do something useful with that energy. I don't know a lot about electric motors so my question is: would it be possible to have an MGU-H with two windings with separate control, one 'connected' to the ES and the other to the MGU-K? If so, would it be possible to have one winding on generator mode (using energy coming from MGU-K) and the other on harvesting mode to store this energy into the ES?

If this would work and it is legal, you could potentially recover more kinetic energy than 2 MJ per lap.

I'm sorry if this idea sounds ridiculous, I just don't have enough knowledge about electric motors to know any better.

Per wrote:if the MGU-H can do something useful with that energy

What about areas like bearings, or better lighter insulation to the windings, or the armature(does an MGU-H even use an armature?).gruntguru wrote:Silver is about 5% better as a conductor. Sounds great but that only means the resistive losses can be reduced by up to 5%. Considering that those losses are probably only 2% (2.4 kW) the potential saving is perhaps 0.12 kW?

125.000 rpm limit? Not sure.hollus wrote: Is there anything conceptually preventing using the exhaust recovery to help the gases along their way instead of to hinder them? Or maybe this is common knowledge?

Radial inflow turbine doesn't work that way. If you increase its speed by driving the shaft, the backpressure on the engine increases.hollus wrote:It is always mentioned how quali modes might bypass the MGUH and use the wastegate to avoid backpressure if recovery is not being used, but in principle, couldn't the MGUH overspeed from its ideal recovery speed (on purpose) and actually pull gases from the exhaust? This would reduce the backpressure even further, possibly to negative values and even directly drive the engine to a limited extent by pure blowing. Probably a bitch to tune when it is linked to the compressor, but it might come handy in limited situations. And remember, "it may be clutched".

Is there anything conceptually preventing using the exhaust recovery to help the gases along their way instead of to hinder them? Or maybe this is common knowledge?

I have 11 of the circuits in a spreadsheet with braking percentages from Brembo.NL_Fer wrote:To exceed the 2MJ limit, a car would need to brake for over 16s a lap, never gonna happen in F1.

Hamilton was interviewed in Baku ... and said that braking will be a significant issue in 2017.henry wrote:Next year braking times will go down.

Thanks. An interesting perspective. I hadn't heard it but since there are some circuits that are brake wear critical now it is not surprising.R_Redding wrote:Hamilton was interviewed in Baku ... and said that braking will be a significant issue in 2017.henry wrote:Next year braking times will go down.

The cars will be heavier ,with much larger tires ...but the carbon discs will be the same as this year as no supplier is building larger one currently..and they have a long tooling/lead time.

So braking times will most likely go up.

In qualifying yes. Nice new disks no worries about wear. But in the race the higher total energy going into the disks will wear them more and so drivers will have to forego some of the potential stopping power in the interests of getting to the end of the race. One way to do that is lift and coast. In 2017 I expect more drag and so more speed loss in the coast phase. Another technique will be not to brake as hard. Since teams use brake heat to manage tyre temperatures there may be merit in not using all the braking force available so as to keep the brake, and hence tyre temperatures in the right window.NL_Fer wrote:No, when braking full at high speed, when the car is slowing down, brake pressure has to be reduced by e driver to prevent lockup. With wider tyres, a driver can keep maximum brake pressure for a longer period, because of more tyre grip.

This will give 1: more brake wear 2: more brake heat 3: shorter stopping distance 4: shorter brake times.