Hello J.A.W.

You write:

“Hi Manolis, you write "Its not a 2-stroke engine..

Is your rotary valve design capable of effective operation as a 2T, if externally scavenge pumped?”

Here is a PatRoVa Rotary Valve for 2-stroke engines:

more at

http://www.pattakon.com/pattakonPatRoVa.htm

You also write:

“Can it withstand CI/forced induction pressures? Or be HCCI capable?”

Quote from a post to another forum:

“Suppose that the rotary valve and the cavity on the cylinder head are both made of steel or of spheroidal graphite iron.

1. Take 1ton (2,200lb) force acting on each oppositely arranged front through the big diameter (say of 10cm2 section area) and short (say 25.4mm / 1’’) hub /shaft.

For simplicity forget the bending loads.

The tension load causes an extension of the hub (i.e. an increase of the distance between the two oppositely acting fronts) of about 0.001mm (one micron).

2. Take 100 degrees Celsius (180 F) temperature difference between the PatRoVa rotary valve and the part of the cylinder head between the two oppositely arranged fronts (i.e. the cavity).

Such a temperature difference causes a 0.03mm change in the distance between the two oppositely arranged fronts (i.e. 0.015mm per side).

As you see, the architecture of the PatRoVa rotary valve is anything but vulnerable "to distortions introduced by differential heat fluxes and pressure differentials".

To further reduce the distortion introduced by differential heat fluxes, a future option is to use INVAR, or other low coefficient of thermal expansion alloy, for the rotary valve and the cavity.”

However, if I had to make a 2-stroke for a motorcycle, this:

single-cylinder PatAT 2-stroke (built-in asymmetric transfer) seems superior. Imagine it as a direct injection turbocharged Diesel (or gasoline), with the turbocharger being the scavenging pump.

This Cross-Radial version of the above single-cylinder:

seems having all the good characteristics required by an airplane of helicopter.

More at

http://www.pattakon.com/pattakonPatAT.htm

For RC / model engines (drones etc), this simple design (three moving parts in total):

combines asymmetric intake, asymmetric transfer, crankcage scavenging etc.

The ability of the PatRoVa Rotary Valve to operate at extremely high revs makes it way superior than the poppet valves in 2-strokes because in a 2-stroke a poppet valve has to open and close twice as fast as in a 4-stroke (from difficult to impossible, depending on the revs).

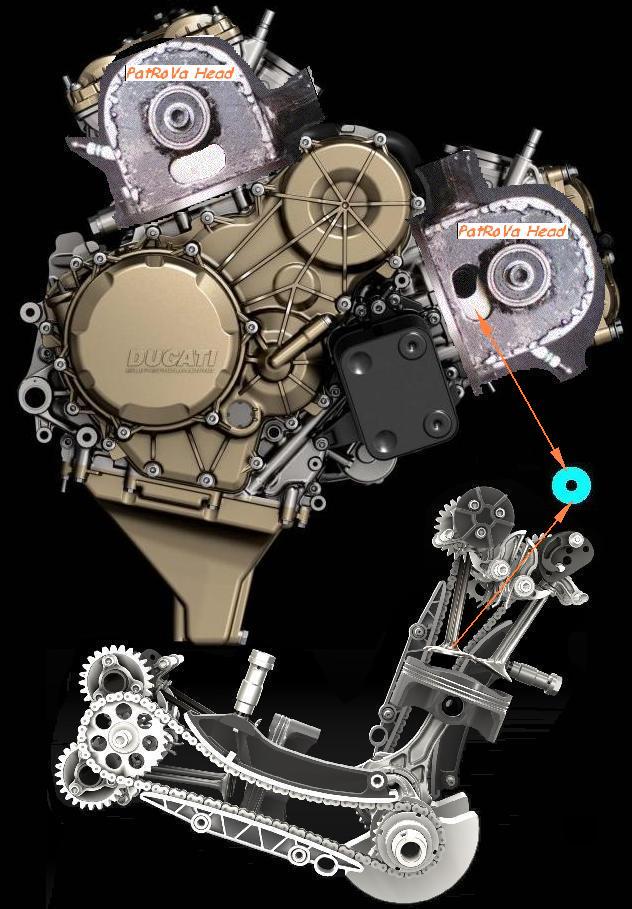

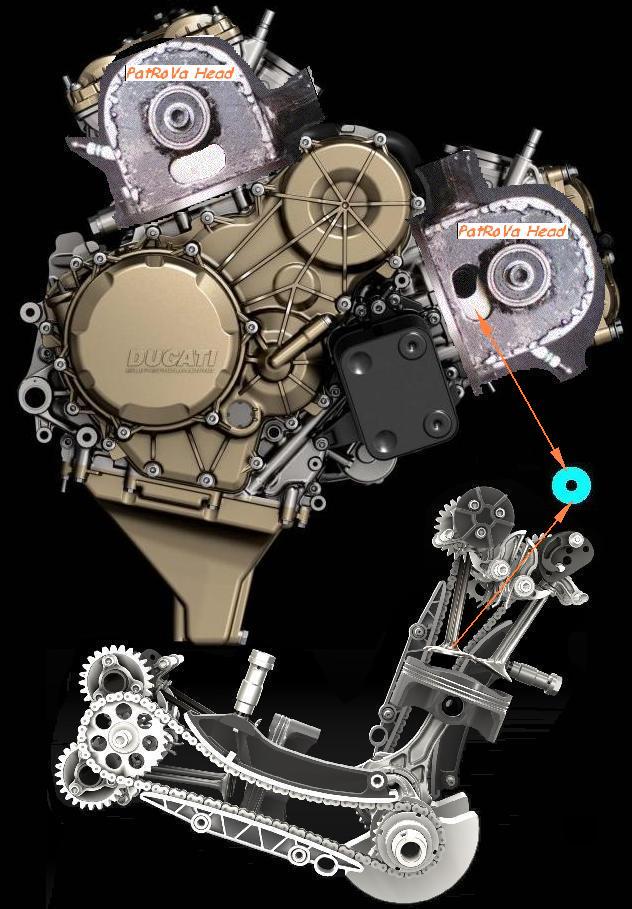

Talking for high revving poppet valves, the Ducati Panigale (Desmodromic cylinder heads) is regarded by many as the top technology today.

If the underneath mechanism (pistons, connecting rods, crankshaft, block) of the Duacti Panigale could stand 15,000rpm (the current rev limit is 12,500rpm), or 20,000, or 25,000rpm, the PatRoVa Rotary Valve would be the way:

Since we were talking about the Portable Flyer, here is a stereoscopic drawing added to the

http://www.pattakon.com/pattakonPatTol.htm web page a couple of days ago :

Thanks

Manolis Pattakos