From the 3rd page of your first link (Napier Deltic):

The exhaust opens 34.5 degrees before the inlet (or transfer).

The exhaust closes 5.5 degrees before the inlet (or transfer).

From the 4rth page of your first link (Napier Deltic):

This means that one piston in each cylinder must lead the other by 20 degrees.

. . .

The ideal exhaust port lead for this type of engine is that which allows the combustion pressure to fall below the scavenge pressure at the point of inlet port opening. The inlet port is closed after the exhaust port, and thus the blower supercharges each cylinder after the exhaust port has closed. During the period that both ports are open, the air flow from the blower scavenges the cylinder of all exhaust gases and assists in cooling the cylinder walls and piston crowns.

From http://www.pattakon.com/pattakonPatAT.htm :

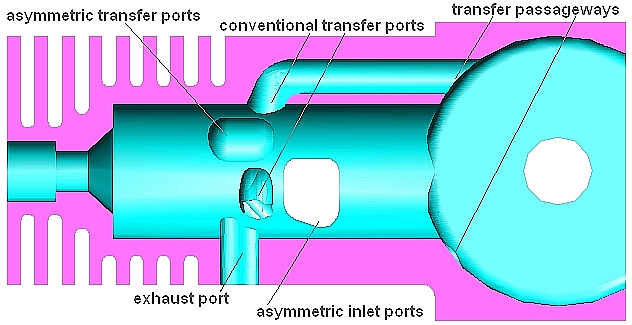

The above PatATi model / RC engine (ring-less piston, bore less than, say, 1 inch) comprises only three moving parts, as the simplest 2-strokes: a piston, a connecting rod and a crankshaft.

No matter how simple it is, it offers as asymmetric intake as the best “reed valve 2-strokes” (which cannot run at really high revs) and as the best “rotary valve 2-strokes”.

It also offers as asymmetric transfer as the Opposed Piston Junkers and Achates Power 2-stroke engines. If desired, the transfer can close after the exhaust (as happens in the famous Napier Deltic).

It is funny: the Napier Deltic:

a monster engine, one of the most advanced / complicated / expensive reciprocating piston engines ever, had to compromise with the wrong port timing (20 degrees phase difference between each pair of crankshafts), while the above tiny and simple single-cylinder PatATi model engine can achieve the desirable / ideal asymmetry in the intake and in the transfer processes.

I hope it is now obvious that with the PatATi architecture, the most important processes in the 2-stroke engines are substantially changed / affected / improved, while the number of moving parts remains the minimum: a piston, a connecting rod and a crankshaft.

Thanks

Manolis Pattakos