Hello Brian Coat.

You write:

“It got me thinking and I probably need to think more!”

Please do keep thinking.

So far, only few people seem to understand how the PatRoVa operates.

You write:

“Concerning residuals and detonation, what about the exhaust gas pushed into the exhaust/intake port, which does not have to be during overlap period does it, because the port itself 'overlaps'?”

The intake port - exhaust port overlap at the “non combustion” TDC can be from small or zero to huge, as in the poppet valve engines.

In comparison to the poppet valve engines wherein an intake valve almost touches its neighbor exhaust valve providing a short-circuit between the intake and the exhaust through which the fresh charge from the intake valve opening escapes to the exhaust valve opening, in the PatRoVa the intake and exhaust openings are at a substantial distance, at the two ends of the combustion chamber, which is the ideal way for the scavenging of the combustion chamber. The incoming fresh charge pushes out the residual gas cleaning the cylinder.

For instance, take the cylinder head of the Ducati Panigale (photo in recent post) and think the overlap period. In the area between an intake valve and its neighboring exhaust valve it is formed a corridor / a passageway short-circuiting the intake and the exhaust ports: the fresh charge escapes to the exhaust (because it is the easiest / shortest way to follow the fresh charge), leaving the combustion chamber actually un-scavenged unless there is a lot of overlap.

According the previous, the PatRoVa needs substantially fewer (in crank degrees) overlap than a poppet valve engine and achieves a better (through) scavenging of the combustion chamber.

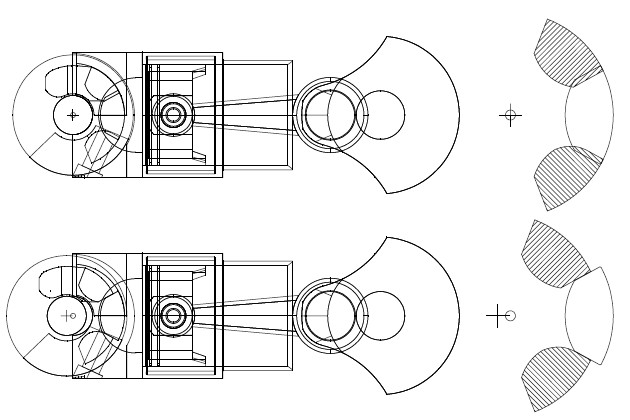

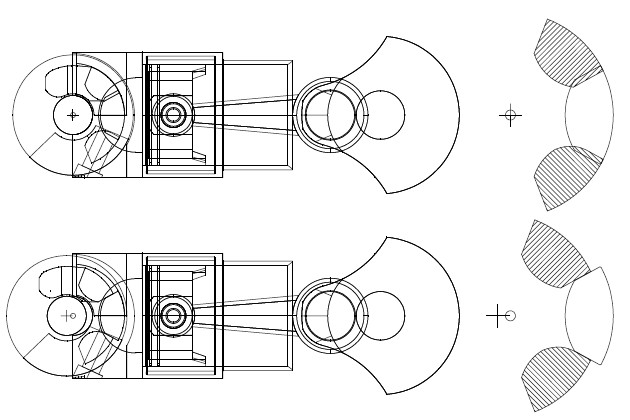

The “zero total force” the {atRoVa rotary valve undergoes makes easy the realization of a VVA wherein, depending on the operational conditions, the translation by a few mm of the bearings of the PatRoVa rotary valve varies the overlap and the duration, like:

With fewer residual gas in the combustion chamber (efficient / clean scavenging as explained above), with substantially higher compression ratio, without hot spots (like the exhaust poppet valves) into the combustion chamber, with a lot of squeeze just before the combustion, with a flat piston crown rid of valve pockets and with a compact combustion chamber with centrally located spark plug, the PatRoVa design seems way better than the poppet valve design as regards the detonation and the residual gas.

Regarding the compactness / smooth-shape of the combustion chamber, regarding also the travel of the flame, just follow the flame in the abovementioned Ducati Panigale to see what I mean.

Bore: 116mm, spark advance: 60 degrees(!), piston crown shape:

And talking for the Ducati Panigalle engine, one of the most advanced engines today, just think how many dozens of PatRoVa cylinder heads can be made at the cost of manufacturing one Panigale Desmodromic cylinder head.

By the way, has the Ducati a more “desmodromic” design than the PatRoVa?

You also write:

“Concerning HCs, even if the leakage is good, would HC's get trapped in the large sealing crevice during compression and released on the exhaust stroke, like they do in the piston top land normally.”

The volume of the “crevice” is tiny. Any leakage goes to the “intake plenum” and waits the next suction to re-enter the cylinder. Only near the end of the expansion a part of the leakage finds the way to the exhaust port of the rotary valve, but this leakage is already burned gas.

You also write:

“Concerning poppet valve sealing, they are a bit non-round when hot and sealing is helped by things like the flexibility of the valve, including the stem; plus a lot of force from gas pressure of course.”

On the other hand, and until the pressure in the cylinder to get high enough to deform the valve head or the valve seat in order to fit with each other (note: most of the compression happens in relatively low pressure, but high enough to cause leakage), a poppet valve seating on a “bit non-round” valve seat, cannot help leaking. And if it is an exhaust valve, any leakage goes to the exhaust unburned, polluting and decreasing the fuel efficiency.

Interesting: when a new design comes along (the PatRoVa in this case), the older designs (poppet valve engines, spherical rotary valves, Cross-Bishop rotary valves) get under the “microscope” once again.

You also write:

”Zooming out, do we see that the need for high rpm to produce power is being reduced by the boosting trend?”

A smaller engine has, among others, lower weight, less friction, lower cost etc. If it is a high revving supercharged engine, it can deliver lots of power when required, being fuel efficient and green etc when only a small fraction of its peak power is required.

A 1000cc turbocharged engine for medium size cars is a common solution today.

A 500cc high revving supercharged engine could be the solution of tomorrow: even lower emissions, even lower fuel consumption, even more power when required.

The PatRoVa design fits with heavy supercharging more than the poppet valve engines (previous post).

The PatRoVa design provides extreme flow efficiency.

The PatRoVa design fits with extreme revs (there is no rev limit for the cylinder head).

Isn’t the combination of boosting with high rpm a better “down-sizing”?

Thanks

Manolis Pattakos