Hello J.A.W.

Thanks for the link.

Quote from page 104 of the link:

RECOMMENDATIONS FOR FUTURE WORK

During this research, a range of two-stroke engine parameters and data have been tested and modeled. However, the engine design may be further optimized for increased efficiency and power density.

Suggestions for further modeling work include:

- Supercharging and asymmetric port timings may further improve both engine efficiency and power density.

. . .”

End of Quote.

Quote from page 16 of the link:

“Asymmetric port timing

Fig 2.7 Asymmetric port timing diagram (Pattakon 2014)

In non-symmetrical port timing, the opening and closing of the intake and exhaust is not-symmetrical which leads to much more complex design.”

End of Quote

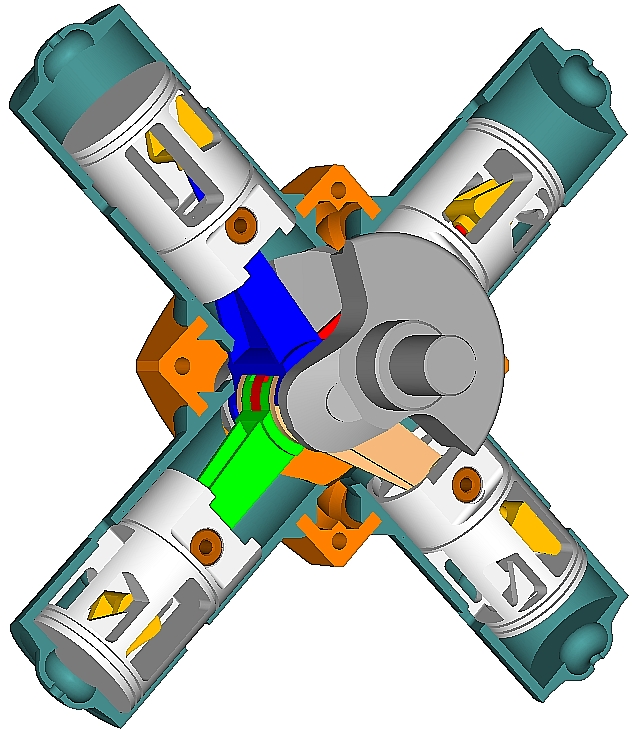

Regarding the “much more complex design” of the PatAT or PatATi 2-stroke engine, I count only three moving parts in total: a crankshaft, a connecting rod and a piston (i.e. as in the simplest 2-stroke conventional engines):

(stereoscopic animation; instructions on how to “look” at it, at

http://www.pattakon.com/pattakonStereoscopy.htm )

The three moving parts are modified to offer both: asymmetric transfer and asymmetric intake.

Is it a “much more complex design”?

A decent modern 2-stroke needs an additional mechanism to control the intake (like a reed valve, or like a rotary valve) and compromises with an inevitably symmetric transfer (the exhaust port stays open substantially after the end of the transfer).

In comparison, the PatATi, without using reed valves or rotary valves or anything else than its crankshaft - connecting rod – piston - casing, achieves a highly asymmetric and efficient intake, and a highly asymmetric transfer (if desired, the transfer ends after the end of the exhaust).

The PatATi is simpler (because, among others, the PatATi uses fewer parts) and better (because, among others, the PatATi offers new options / capabilities not possible before).

You write:

“with oil injection metered into specific areas, consumption/loss by crankcase scavenged 2Ts can match 4T norms”

Orbital tried it but it seems it was one of their weak points (lube starvation).

As regards the bearings (plain bearings or roller bearings), one can solve the problem by sealing them (not easy, but possible).

But the lubrication of the piston skirt / cylinder liner is a difficult to solve problem.

The leaning of the connecting rod creates significant thrust loads between the piston skirt and the cylinder liner.

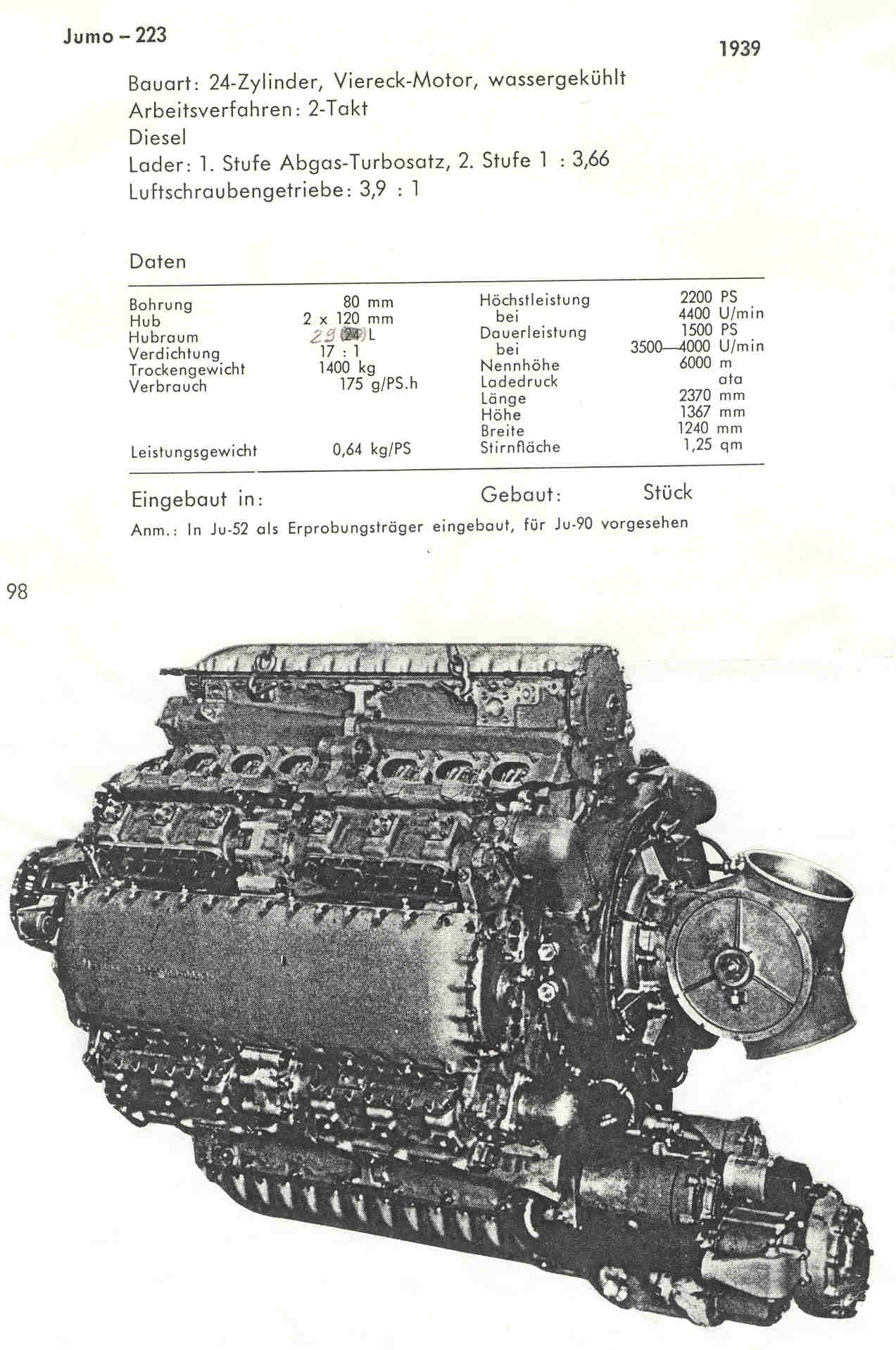

In the 4-stroke engines and in some versions of the PatAT like:

there is a thick oil film between the piston skirt and the cylinder liner enabling "hydrodynamic" lubrication as in the plain crankshaft bearings.

The idea is: “to "over-lubricate" the cylinder liner, apply an oil scraper ring, and then collect the surplus oil, clean it, and recycle it”.

A substantially thinner oil film is adequate to keep the piston rings from contacting the cylinder liner.

In the PatAT engine in the above animation:

The crankcase has four-stroke lubrication.

The scraper ring at the middle of the piston, above the wrist pin, scraps the surplus of oil from the cylinder liner back to the oil pan, from where it is cleaned and recycled.

The cylinder liner area the scraper ring sweeps, is rid of ports.

The path of the lower compression ring and the path of the oil-scraper ring intersect just below the ports.

As in the four-stroke engines, the tiny quantity of lubricant that passes "above" the oil scraper ring lubricates the compression ring(s).

In the conventional 2-stroke the piston skirt abuts on the cylinder liner and transfers similar trust loads; but now there are ports onto the cylinder liner, and the piston skirt passes over these ports. A thin oil film increases the friction and, sooner or later, allows the scuffing. A thick oil film reduces the friction and the possibility for scuffing, in expense of higher specific lube consumption and of worse combustion and emissions.

Achates Power tried the double sided crankshafts architecture in their Opposed Piston Diesels in order to minimize the thrust loads on the cylinder liner.

According them, they achieved specific lube consumption as low as in the 4-stroke engines. The strange thing is that now they are back to the conventional Opposed Piston Design as proposed by Junkers and others long ago.

Another interesting solution of the lubrication problem in the 2-strokes is applied in the PatOP engine:

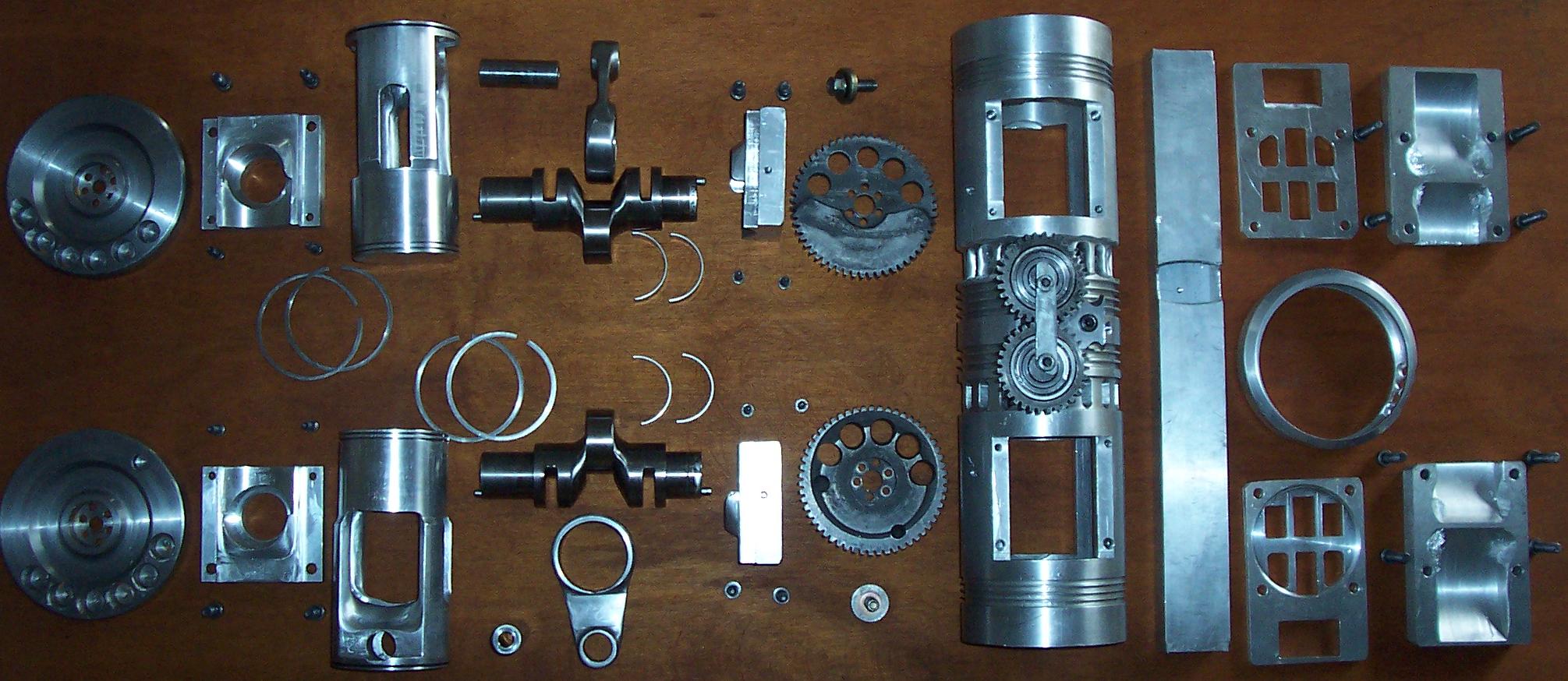

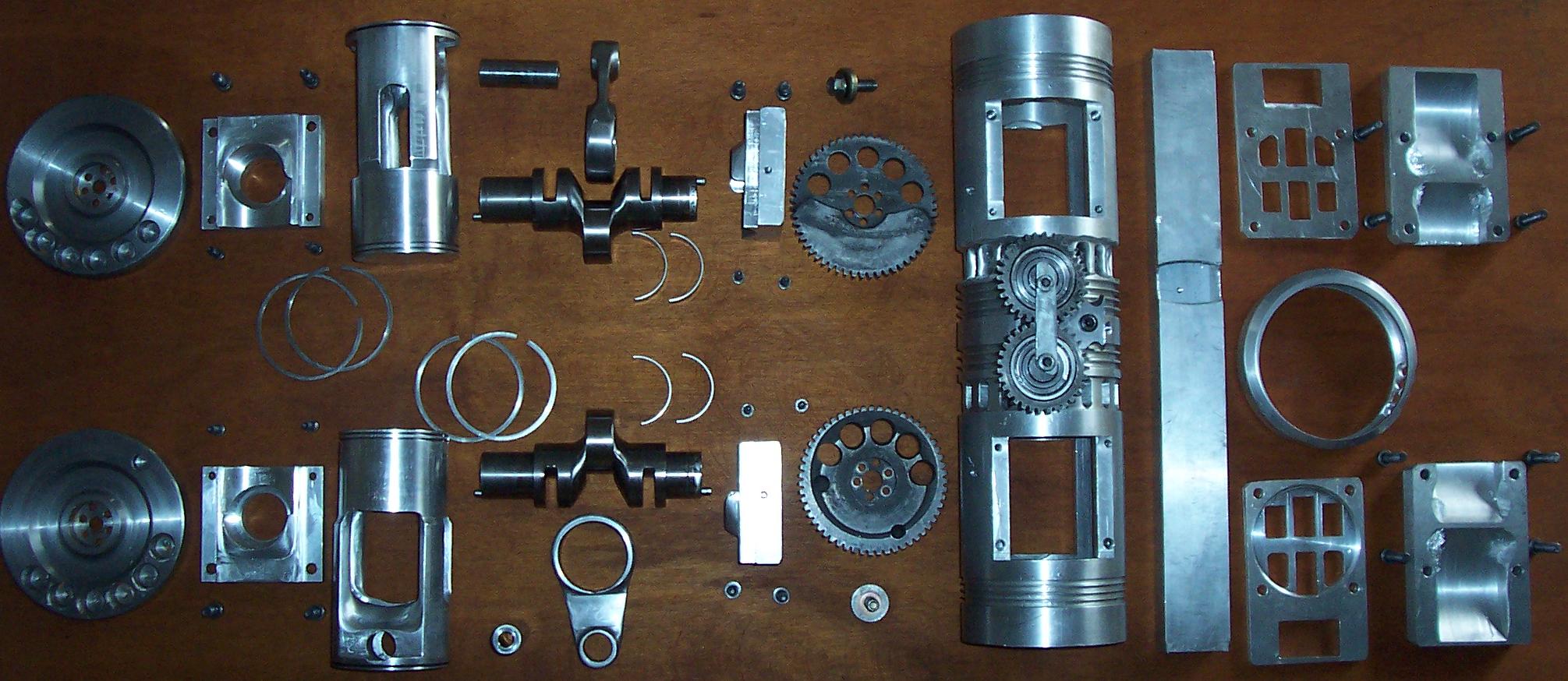

and in the OPRE engine (here they are shown the parts of the OPRE prototype engine; spot on the piston structure and on the location of the wrist pin):

Quote from

http://www.pattakon.com/pattakonOPRE.htm :

“The transfer of the wrist pin - i.e. of the thrust loads - away from the hot combustion chamber and away from the ports, solves another problem of the opposed piston engines: it allows "four stroke" like lubrication and oil consumption.

OPRE's piston skirt can avoid the touch with the hot cylinder wall because the thrust loads are taken at the other side of the piston, onto the cool, rid of slots and well lubricated cylinder wall of the scavenging pump.

In comparison, the piston skirt of the conventional opposed piston engine thrusts heavily onto the hot, especially at exhaust side, cylinder wall, around the port area where the openings restrict the contact surface, requiring plenty of lubricant and inevitably resulting in lubricant consumption.”

End of Quote

Thanks

Manolis Pattakos