Hello Rscsr.

You write:

“Ok you get rid of the "high" forces of the valve return springs.”

Considering the valve train “linkage”, the forces are not just “high”, they are extreme.

In comparison, the other linkage of the engine (crankshaft – connecting rod – piston – cylinder liner) seems ideal for receiving extreme loads (surface “contact” instead of line “contact”, thick lubricant film etc).

You also write:

“But how much power do you think you will save, by getting rid of it?”

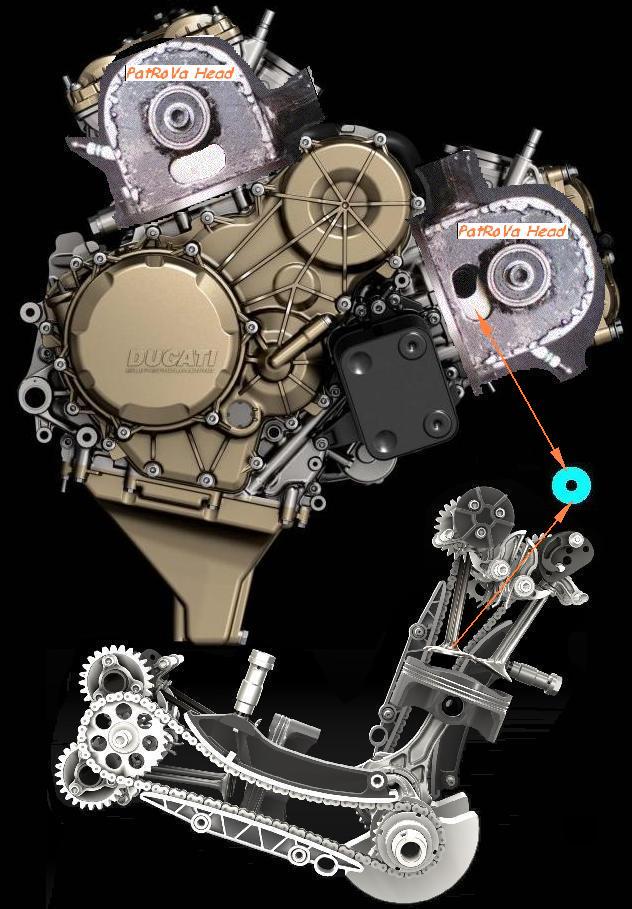

If another motorcycle maker decides to make a replica of the Ducati Panigale keeping all the rest except the Desmodromic cylinder heads which are replaced by conventional cylinder heads with restoring springs for the closing of the valves, keeping the original valve lift profile, things get more than tough.

Just imagine a valve spring providing 280+Kp (600+lb) restoring force and 16mm lift (valve “stroke”).

For ordinary car engines a 28Kp restoring force (i.e. 1/10 of the above) is too much (friction, wear, etc).

Back to Ducati Panigale:

Consider the case Ducati needs / decides to upgrade the Panigale 1299 in order to get substantially more power at substantially higher revs.

The mean piston speed is already too high to increase.

So, what is the reasonable approach?

To further increase the bore and decrease accordingly the stroke; for instance, the diameter increases at 128mm and the stroke decreases at 50mm to keep the cylinder capacity unchanged.

Keeping the same mean piston speed, the present 11,500rpm rev limit goes to 11,500*60.8/50.0= 14,000rpm.

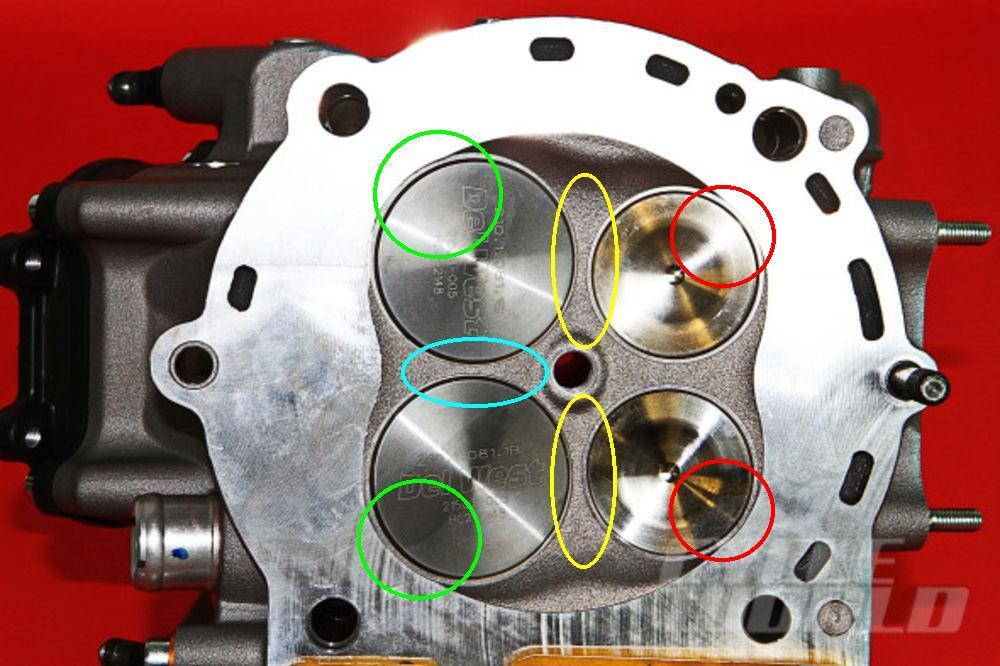

The next requirement for more power is the increased flow capacity of the short (50mm) stroke engine. The valves need to increase in size. Reasonably, the valve diameter increase proportionally with the bore, so the intake valve goes from 46.8mm to 46.8*128/116=51.5mm and the intake valve lift goes from 16mm to 17.7mm.

Compare the increase of the piston acceleration with the increase of the intake valve acceleration:

The piston acceleration increases by 22% ( (50.0/60.8 ) * (14,000/11,000)^2 )

The intake valve acceleration increases by 64% ( (17.7/16.0) * (14,000/11,500)^2 )

And considering the increased mass of the bigger valve, the required force for the motion of the valve is 100% more than in the original intake valve in the normal Panigale 1299.

I.e. the 280Kp (600lb) restoring force becomes now 560Kp (1200lb), otherwise the short stroke (50mm) Panigale 1299 cannot operate at 14,000rpm.

Imagine a valve spring applying 560Kp (5,600Nt) restoring force at a 17.7 “stroke”. In a first approach, the energy required to compress this spring is 5,600Nt * 0,0177m = 99 Joules, and at 14,000rpm (i.e. 7,000rpm of the camshafts) it means 99J * 7,000/60 = 11,5kW of power.

Say, half of this is returned to the kinematic mechanism.

There are 8 valves in total (the exhaust valves have shorter valve lift but they are heavier).

The required power for the two cylinder heads at 14,000rpm is: 11.5kW * 0.5 * 8 = 45kW = 63PS

Isn’t it hard to believe?

And all this lost power (45kW) heats the lubricant and the engine.

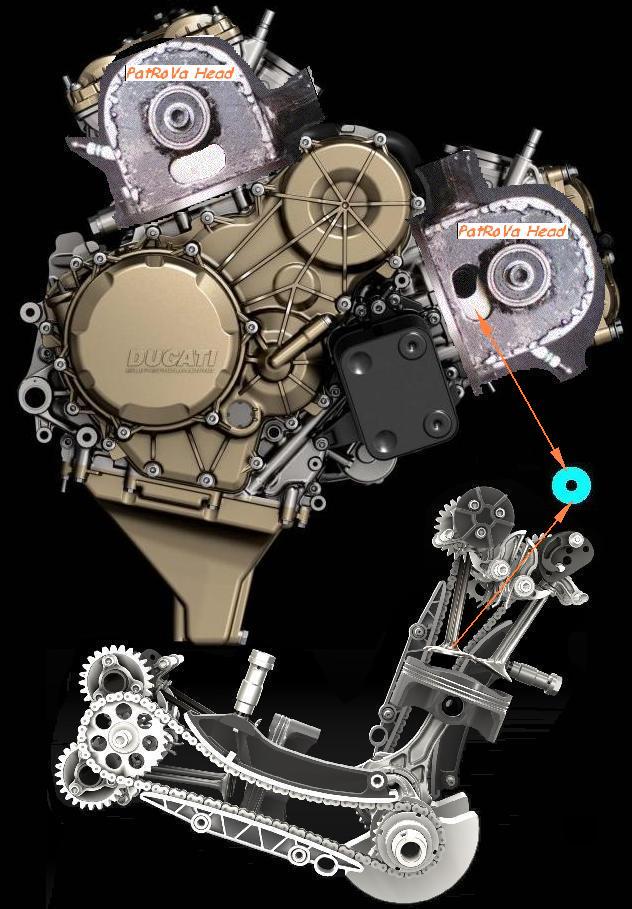

Now, consider the same 128mm bore x 50mm stroke Ducati Panigale, this time with PatRoVa cylinder heads.

Revving the PatRoVa rotary valves at “only” 7,000rpm (i.e. 14,000rpm of the crankshaft) is more than easy (there are no reciprocating parts; only a balanced “wheel” is spinning at constant angular speed) and requires several dozens of times fewer power just to keep it spinning .

Considering proportional increase of the power with the revs, the 205PS (at 10,500rpm) of the original Ducati Panigale 1299 will go to 250PS (at 12,800rpm) of the short stroke (50mm) PatRoVa Panigale.

However, it is not yet calculated the power loss in the Desmodromic Valve Train of the original Panigale 1299.

Applying the above calculations at only10,500rpm wherein the original Panigale makes its peak power (205PS), the power loss in the Ducati valve train is some 25kW (35PS).

Adding this power (which is not lost in the case of the PatRoVa Panigale 1299) to the above calculated 250Ps, the peak power goes to 285PS at 12,800rpm (only 21.3m/sec mean piston speed). It is a 40% increase relative to the original Panigale 1299.

Worth to mention: at 12,800rpm, the piston acceleration of the above PatRoVa Panigale 1299 equals to the piston acceleration of the original Panigale at 11,500rpm (wherein it still operates reliably) ( 60.8 * 11,500^2 = 50.0 * 12,800^2 )

The top Ducati Panigale model (Superleggera, single compression ring, titanium exhaust valves, same piston stroke with the 1299, 112mm bore) makes its peak power at 11,500rpm and has the rev limit at 12,500rpm (25.3m/sec mean piston speed).

The PatRoVa Panigale at 13,800rpm (only 23m/sec mean piston speed, same piston acceleration with the Superleggera at 12.500rpm) ) can, properly tuned, make:

285PS * 13,800 / 12,800 = 307PS at 13,800rpm.

This is a 50% increase as compared to the original Panigale 1299.

The above are only a theoretical approach.

Objections?

Thanks

Manolis Pattakos