Hello Muniix.

You write:

“Maybe one should look at the Zoche Aero Diesels, they exist now two stroke diesels for aircraft, decades of development went into these. You can buy one today.

. . .

Many advantages, highly optimised from Germany, a friend of mine held development parts in his hands a decade or so ago.”

Which are the advantages?

I only see a conventional 2-stroke in radial arrangement.

Are there any differences?

If you can’t tell the difference, there isn’t any.

What about the lubrication? Who keeps the lubricant from entering into the combustion chamber and from escaping to the exhaust?

Is there any real innovation in the Zoche design?

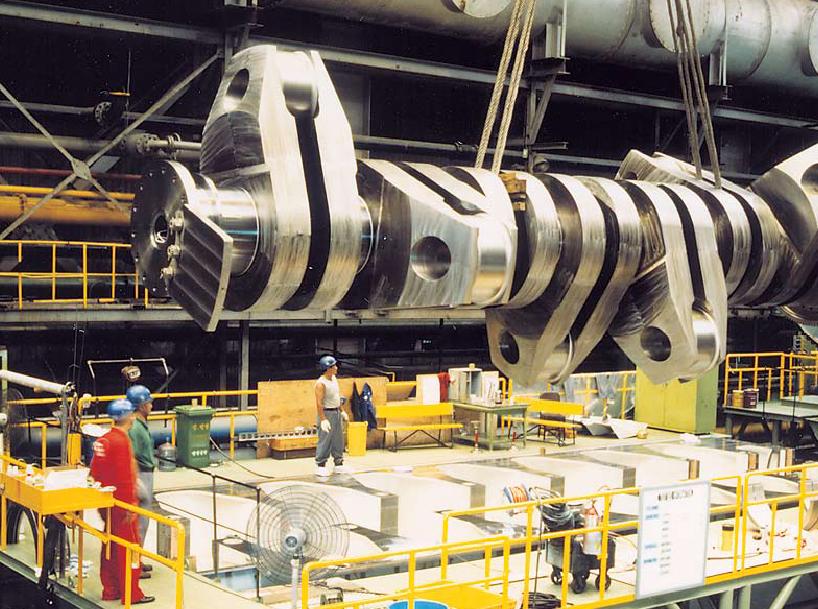

For comparison, here is a Cross-Radial PatAT 2-stroke aero Diesel:

Quote from

http://www.pattakon.com/pattakonPatAT.htm :

“The separating plate at the middle of the piston seals the space underneath the piston crown from the crankcase.

Through openings in the cylinder and in the piston, the pressurized air or mixture enters into the combustion chamber either directly or indirectly (it initially goes into the space underneath the piston crown and then, through a piston port controlled by the connecting rod and then through a transfer port controlled by the piston, it gets into the combustion chamber).

The crankcase has four-stroke lubrication.

The scraper ring at the middle of the piston, above the wrist pin, scraps the surplus of oil from the cylinder liner back to the oil pan, from where it is cleaned and recycled.

The cylinder liner area the scraper ring sweeps, is rid of ports.

As in the four-stroke engines, the tiny quantity of lubricant that passes "above" the oil scraper ring lubricates the compression ring(s).

There are two "asymmetric" transfer ports disposed in series with respective piston ports (which are controlled by the connecting rod); there are also three conventional transfer ports (they open after the exhaust port).

The arrangement with the oil scraper ring fits, among others, with compression ignition (Diesel) engines: efficient lubrication of the crankcase and of the piston skirt (wherein the thrust loads are taken), asymmetric transfer, turbo charging, scuffing resistance etc.

The above even firing Cross-Radial PatAT is as vibration free as the best V8, it has firing intervals equal to those of a V8 four-stroke, it has four-stroke lubrication (plain bearings, forced / splashed lubrication in the crankcase, oil scraper rings), it can utilize a central scavenging pump (a turbocharger, for instance), etc.

You also write:

“One has to think of equivelence when doing comparisons, clearly a mistake someone with an engineering or physics degree would not make.”

You don’t know what it is to be an engineer. Don’t appreciate them more than what they deserve.

You also write:

“Bishop . . .know how to write patents, . . . , that was what gave them their $15 million a year research and developent budget.”

Do you know how it is to apply for a patent, or how the inventor feels when a patent is finally granted?

Isn’t it a pity that after all this millions there is not one running prototype on the roads?

You also write:

“Marine engines use mhp, marine hp”

Marine hp?

Please be more specific.

Thanks

Manolis Pattakos