Hello all.

Manolis wrote:

“What is the difference (regarding the lubrication and the lubricant consumption) when:

a piston (of a ported “cross-head” two-stroke) moves, without thrust loads, over the ports of the cylinder liner,

and when:

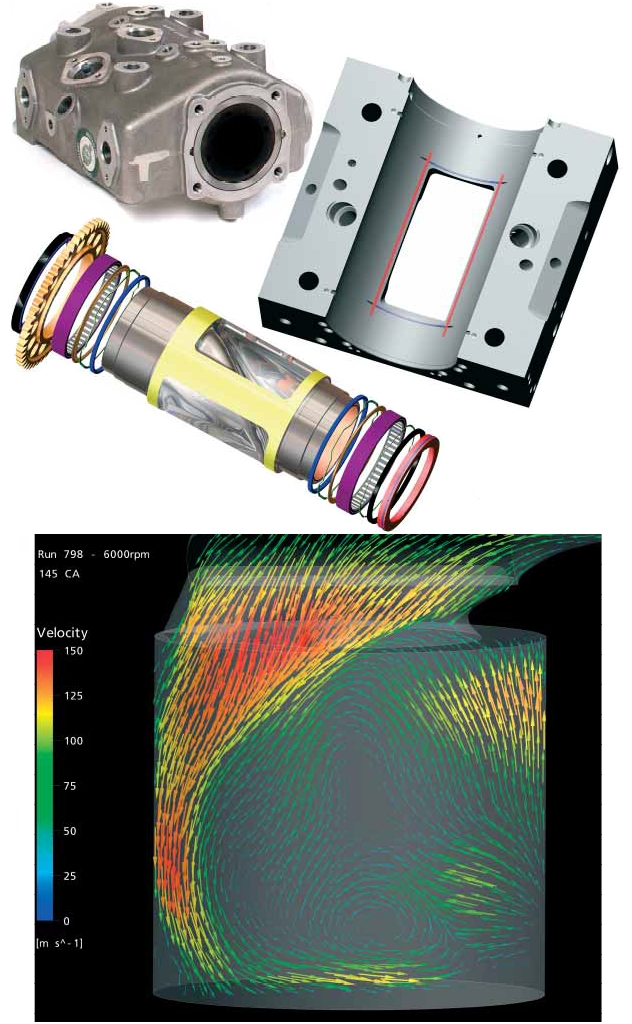

a Bishop rotary valve (of a 4-stroke engine) moves inside the cylinder head.

In both cases there are ports / openings (on the cylinder liner, in the first case, on the rotary valve, in the second case) and sealing means passing over the ports.”

Mudflap replied:

“I don't know what the oil consumption of the bishop valve nor that of a wartsila engine is. And neither do you. How these engines relate to yours is beyond me.”

QUOTE from

http://www.pattakon.com/pattakonPatMar.htm

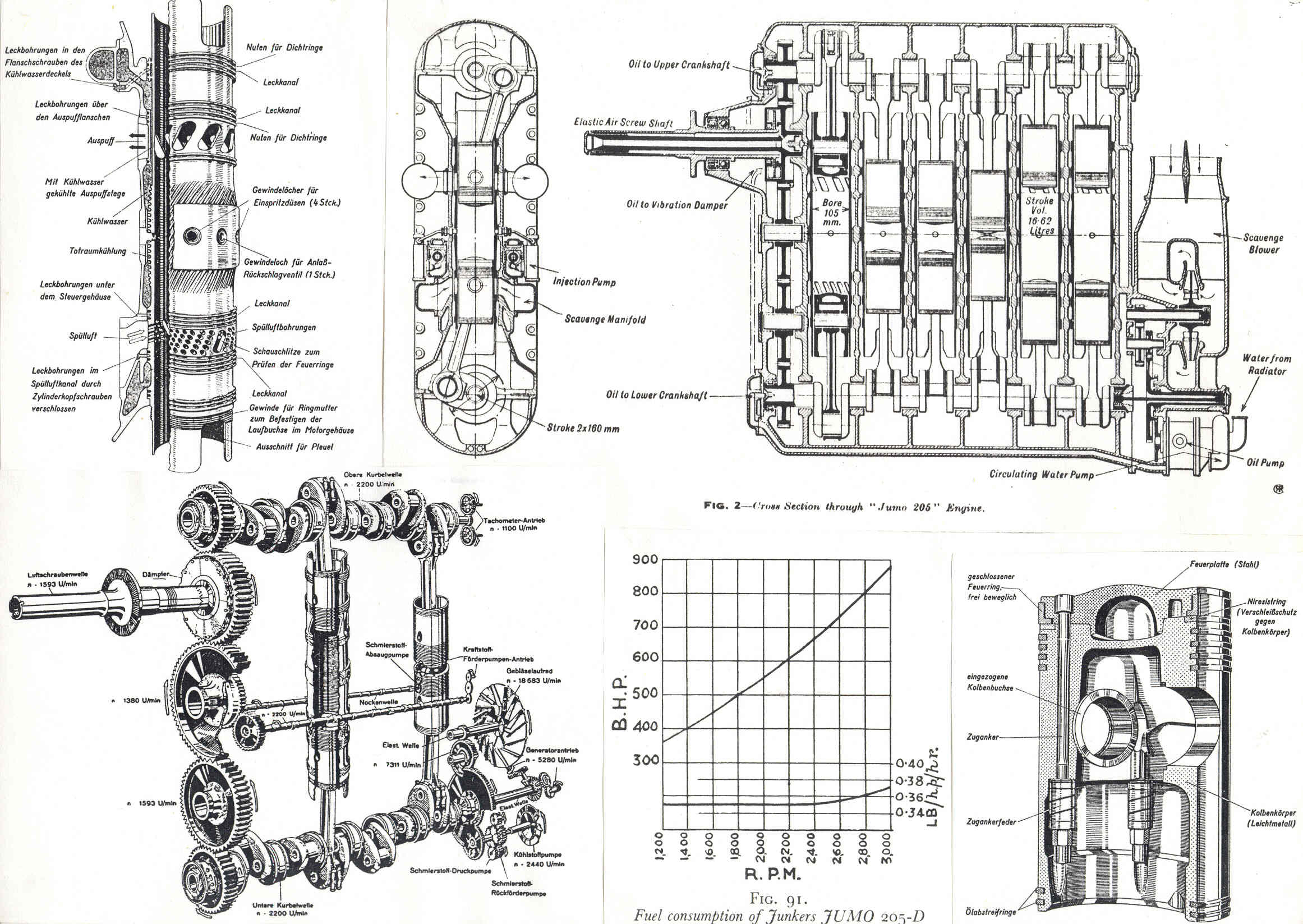

“The problem as defined in Wartsila's(*) Technical Journal, Feb 2010 (click

http://www.pattakon.com/tempman/Wartsil ... 2_2010.pdf )

"A slightly more ambitious idea is to apply the four-stroke trunk piston engine cylinder lubrication concept to the two-stroke crosshead engine, i.e. to "over-lubricate" the cylinder liner, apply an oil scraper ring, and then collect the surplus oil, clean it, and recycle it. This will of course be a radical change of concept, and whether or not it is viable remains to be demonstrated, but an outline exists and a patent is pending. The aim is to increase scuffing resistance and to achieve the same low specific oil consumption level as on the four-stroke trunk piston engines."

End of QUOTE

The PatMar engine presented at the above link is the only solution, so far, of the problem.

Manolis wrote:

“According the practice you are wrong: is there anything that prevents MAN and Wartsila from using it instead of the current cross-head with the flat sliders and the flat slide-ways?”

Mudflap replied:

“How do you know ? Do you have engineering drawings of either of those engines ? The profile has sub-millimeter deviations from flat - how can you tell it's not profiled from those images ?”

All the giant marine (and electric power generation) 2-strokes use the flat cross-heads.

The internet is full of such designs (just get into Wartsila’s web site and download hundreds of PDFs showing slat-cross-heads).

If you know one using “barrel” cross-head show it here.

Mudflat wrote:

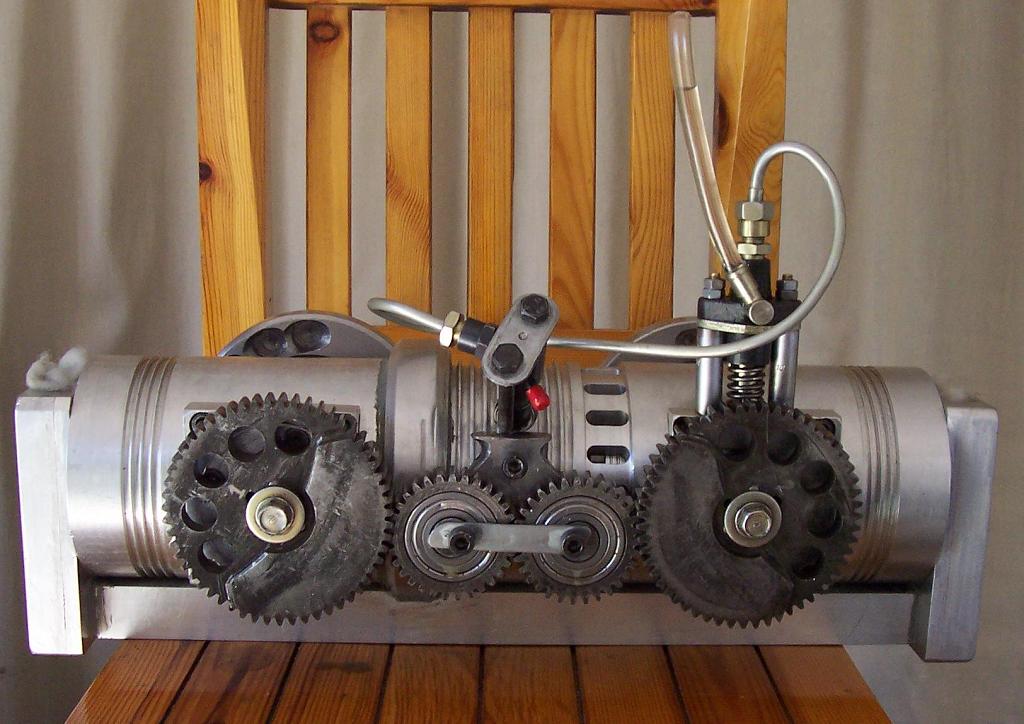

“Your only arguments seem to consist of spamming the same pictures and animations over and over again. I am pretty sure you have posted some of them dozens of times already. You've based your designs on a bishop rotary valve, a wartsila engine and a ww2 engine and claim it has the same advantages as all of them with none of the cons.

I've googled pattakon and you seem to have been spreading the same false claims all over the internet for the last 15 years! The only tangible evidence you have produced is a couple videos of running engines grinding themselves to death, stop motion animations of some badly made components on a chair and ms paint simulation of in cylinder flow, and masses of internet images that do not even remotely relate to your designs.”

Everything is relative.

The EcoMotors OPOC and the Achates Power Diesels are relative to the OPRE, PatOP and PatPOC opposed piston engines.

The Cross-Watson-Bishop rotary valve is relative to the PatRoVa rotary valve.

The PatAir is relative to the MultiAir of FIAT / Chrysler / Alfa Romeo / Schaeffler-INA.

The DVVA is relative to Ducati’s DESMO.

The pattakon VVA’s are relative to BMW’s valvetronic, to Honda’s VTEC, etc.

The PatMar is relative to Wartsila’s marine 2-strokes.

The PatWankel is relative to the Wankel and to the Liquid piston engines.

The constant velocity joint of pattakon is relative to the TCVJ.

EcoMotors with one only project (OPOC engine) is in the Internet for 20 years and thousands of articles have been written about the OPOC so far.

Thanks

Manolis Pattakos