Hello Pinger.

You write:

“Perfect balance is laudable but not absolutely the last word.”

Think of a lightweight 800cc single cylinder engine “secured” on your shoulders:

You also write:

“Torsional issues with opp piston: Fair enough, if you want to dismiss Ricardo's findings. I don't.”

My post is not about dismissing “Ricardo’s findings”; it is about finding what causes “Ricardo’s findings”.

It explains the “torsional issues” observed by Ricardo in Opposed Piston engines having extensive phase difference between the two crankshafts.

So, take another read. It is a simple explanation.

You also write:

“Supercharging (charging the cylinder to a pressure higher than prevailing ambient pressure) is not possible without adequate filling time after exhaust port closure.”

No.

QUOTE from

http://lingualeo.com/pt/jungle/how-does ... 40#/page/1

“Specific to EMD two-stroke engines (567, 645, and 710):

The power stroke begins at TDC [0 degrees];

injection of fuel leads TDC by 4degrees [356 degrees], such that injection of fuel will be completed by TDC, or very shortly thereafter;

the fuel ignites instantaneously), after which power stroke the exhaust valves are opened thereby greatly reducing combustion gas pressure and temperature, and preparing the cylinder for scavenging,

for a power stroke duration of 103 degrees

Scavenging begins 32 degrees later, at BDC–45 degrees [135 degrees], and ends at BDC+45 degrees [225 degrees], for a scavenging duration of 90degrees;

the 32 degree delay in opening the scavenging ports (thereby terminating the power stroke),

and the 16 degree delay after the scavenging ports are closed (thereby initiating the compression stroke), maximizes scavenging effectiveness, thereby maximizing engine power output, while minimizing engine fuel consumption.

Towards the end of scavenging, all products of combustion have been forced out of the cylinder, and only "charge air" remains (scavenging may be accomplished by Roots blowers, for charge air induction at slightly above ambient, or EMD's proprietary turbo-compressor which acts as a blower during start up, and as a turbocharger under normal operational conditions, and for charge air induction at significantly above ambient,[2]

and which turbocharging provides a 50 percent maximum rated power increase over Roots-blown engines of the same displacement).

The compression stroke begins 16 degrees later, at BDC+61 degrees [241degrees], for a compression stroke duration of 119 degrees”

END OF QUOTE

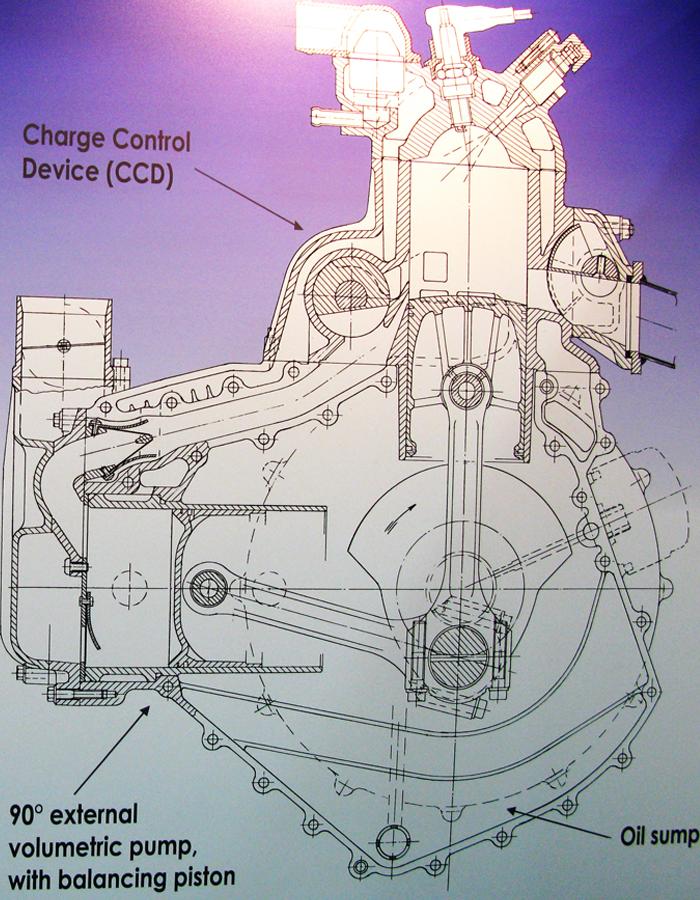

Here is an EMD 2-stroke:

and here it is shown an EMD burning natural gas:

So, we have a turbocharged 2-stroke Diesel that closes the exhaust valves 16 degrees after the closing of the transfer, and yet it provides a 50% maximum rated power increase over Roots-blown engines of the same displacement.

So, take another read of the posts and let me know if something is confusing.

You also write:

“That small end on the Honda V3 is horrible. Are you still happy to add weight to the upper end of a con rod Manolis?’

? !

Thanks

Manolis Pattakos