According an Issue Notice of the US Patent and Trademark Office:

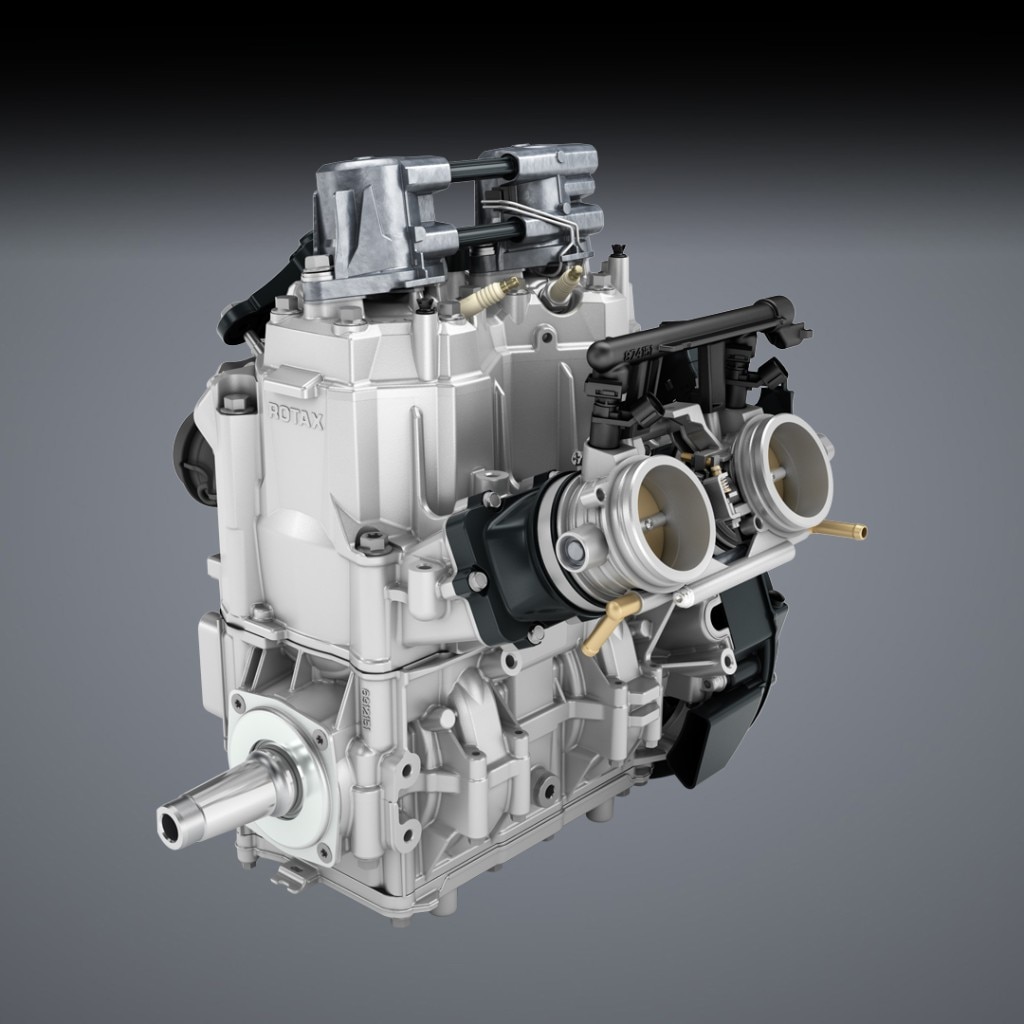

a patent is granted for the PatRoVa Rotary Valve.

The patent number is US9,677,434.

Thanks

Manolis Pattakos

Who knows? I was just struck by how all the 2T tractors of the era arrived at a similar shape for their exhausts. 4T pipes were never so shapely but possibly they were less of a fire hazard re sparks. If ever I get the chance to peer into one of those tractor pipes - I'll take it.

Nope. Only that not all tractors of the type feature it. Possibly something to do with cold starting - being 'hot-bulb' engines, there was something of a ritual to be enacted prior to firing up. They were crankcase scavenged though - but no mention of lubrication (fuel was injected directly into the 'bulb')

Valid question re a Brooklands bike.Tommy Cookers wrote: ↑24 May 2017, 09:30

the Garelli seems to have used a straight pipe before 1925

ie is the photo from Brooklands ? - are there later photos of Garellis ?

That's pretty much the way that divergent cones adopted by those racing outboards came to be as well I think. In their case, ''sucking out the heat'' was paramount. The development of expansions with a convergent cone appears to be a little accidental also - making efforts to quieten the megaphone, some found the engine ran better. I guess the science of calculation came later. Possible I suppose that many were working completely oblivious as to what others were doing and had done before. I don't suppose if you'd just 'invented' the expansion chamber that was giving your bikes such an advantage you'd be telling everyone you got the idea from a tractor...Tommy Cookers wrote: ↑24 May 2017, 09:30in a 1920s motorboating magazine the writer describes giving his motor a tuned length (plain) pipe by experiment with a slip joint

iirc gaining 6 knots from the inboard 2 stroke

Business hat on;. Why else would one spend money on something if it wasn't giving pleasure etc. To make s return on the investment.manolis wrote: ↑25 May 2017, 06:04Hello all.

According an Issue Notice of the US Patent and Trademark Office:

http://www.pattakon.com/PatRoVa/PatRoVa ... _Issue.gif

a patent is granted for the PatRoVa Rotary Valve.

The patent number is US9,677,434.

Thanks

Manolis Pattakos

Muniix wrote: ↑25 May 2017, 16:08I still haven't got any answer or proof of your claim that your Patrova head can achieve the VE you keep claiming. I have asked many times, only response if any is a deflection.

Then i am the I've that gets my posts deleted and abused, when clearly I'm not the one making unjustified claims.

I've been told these posts are hilarious at certain F1 teams. Marc stop wasting your time on this ....., But they are so funny, you take him down so well, causing him to over react in some instances, "how big big enough that you could put a while Bishop valve through it"

Pretty sure some (oil injected) 2T outboards allow for emergency return to port at very low throttle with an empty oil reservoir. Confirming how little oil they need at low load.

Is 2T oil a problem because it is additional to fuel when running at stoichiometric (or richer) and burning is incomplete due to lack of oxygen? My car when the oil control rings were shot and was using 0.5l of oil for every 25l of fuel still passed UK annual MOT tests with a 200ppm limit for UBHC and never showed blue smoke. In its case though, the suspicion is that the excess oil was compensated for by reducing fuel (under Lambda sensor control). For lower duty (say 75hp/litre specific output) 2T, could the fueling not be reduced to compensate for the oil?uniflow wrote: ↑26 May 2017, 12:44The oil problem is a real problem for twostrokes but the raw hydrocarbons out the exhaust is the first big problem to overcome, this new system solves this problem (the mark two) . I have two oil less top ends on test here in my workshop, fourstroke bottom ends, also can't be show here.

In Blair’s Design and Simulation book he cites a quotation attributed to someone back in 1968 essentially saying that when emissions of NOx become problematic, the 2T will be revisited. In what format though?