Hello Tommy Cookers.

You write:

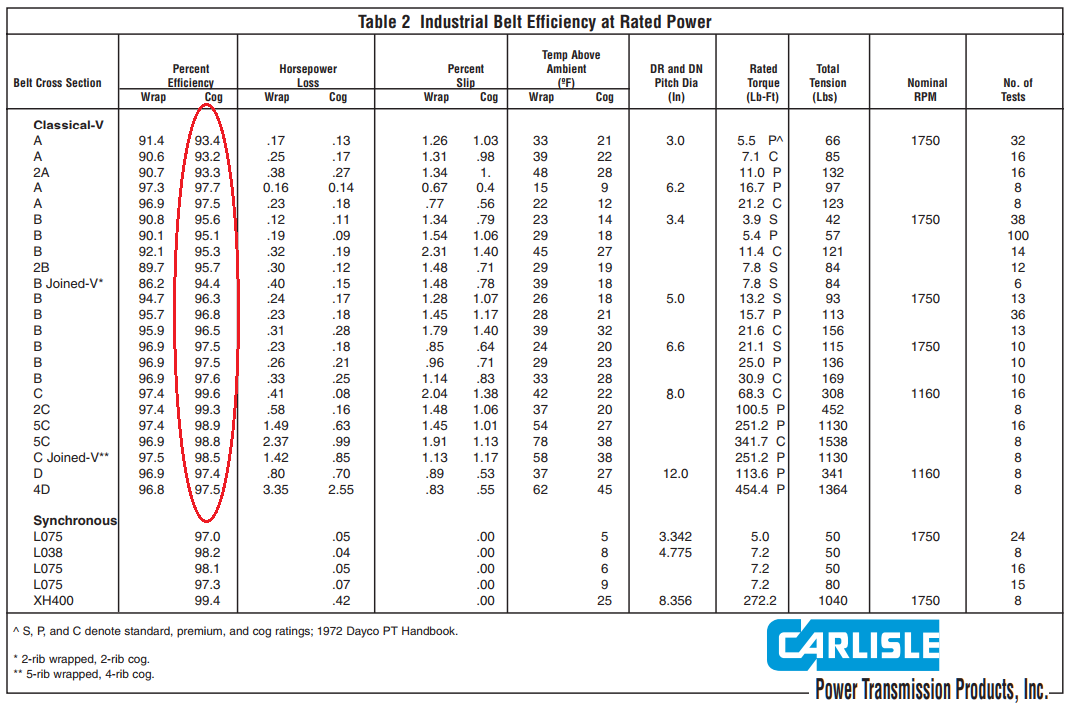

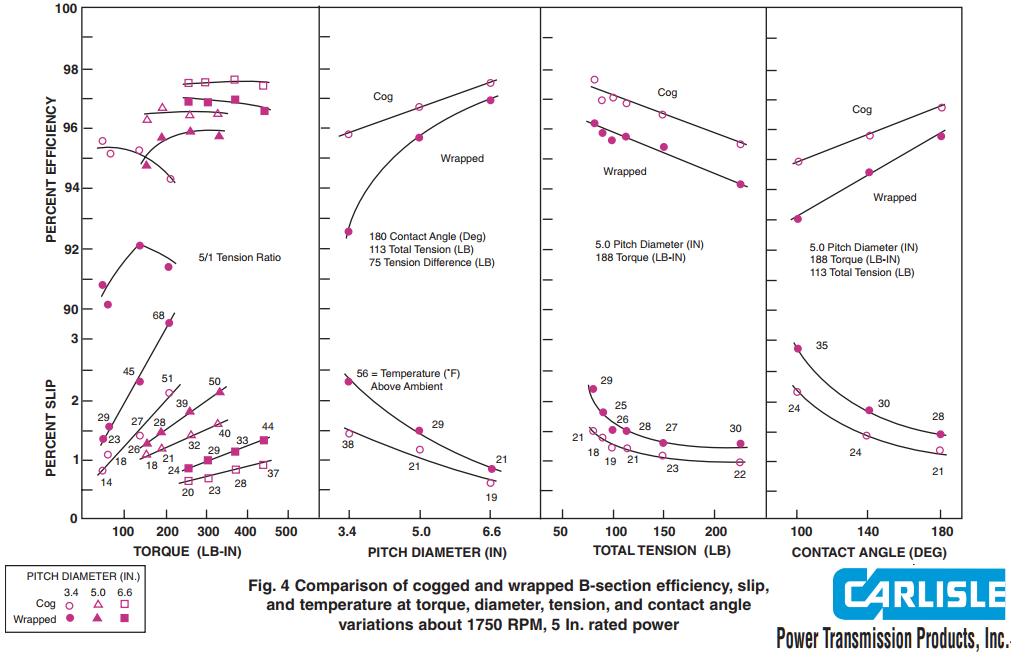

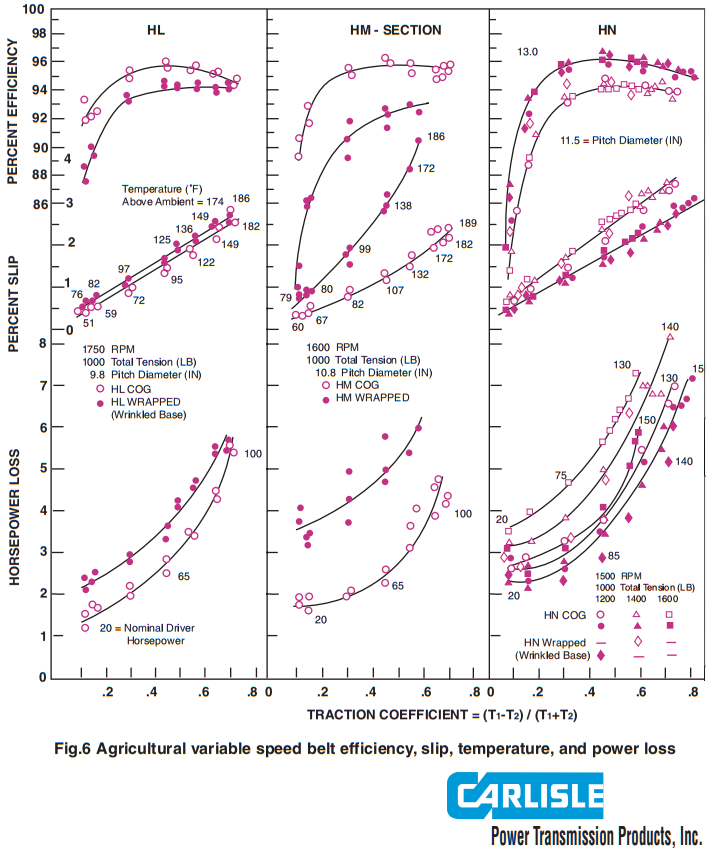

“but your high efficiencies shown come from having large pulley size, high speed, and high power (ie using the belt at full capacity)

so this application won't yield these high efficiencies to the non-ehthusiast customer (the same reason I didn't buy a NuVinci)

with chains and sprockets the low-load/no-load losses are insignificant, not so with a belt and pulleys”

Besides the “transmission efficiency” there other things that matter:

The interruption of the power flow during a gear shift is a significant limitation of the chain / sprockets (derailleur) design, especially for new bicyclers (or aged bicyclers having some issues with their bodies).

Isn’t the interruption of power flow a performance limitation, too?

The easiness of the gear-shifts; the majority of the bicyclers have ten or more gear-ratios, however they use one or two; a wrong gear shift in an uphill is anything but pleasant for the average bicycler.

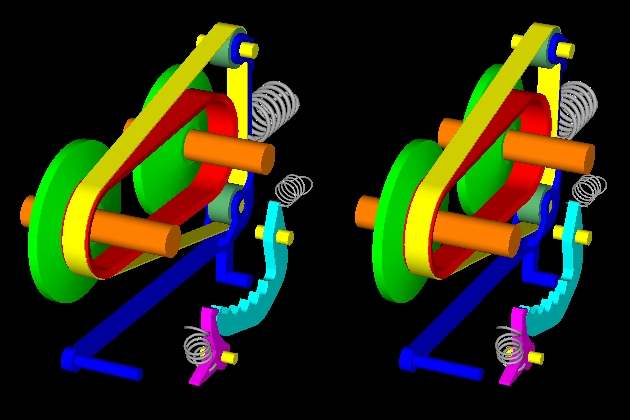

The automatic control over a CVT can keep the pedalling at the ideal rhythm, and the bicycler tireless (the average bicycler has more interesting /pleasant things to do than dealing with a “strange”, at least, gear shifting mechanism.

The overall efficiency.

As in a scooter, similarly in a bicycle the gear train should focus on the optimization of the efficiency of the power source (the bicycler), because there is the most gains.

If the bicycler has to align with the limitations and tricky handling of the bicycle’s transmission, the overall efficiency drops

Simpleminded question: why only 21 gear ratios and not 121 gear ratios?

With 121 gear ratios one can choose a ratio even closer to the ideal one.

However, the side effects are more than the advantages.

With an easy to handle CVT, one can have not 121 but 1021 ratios easily selectable (with the automatic control being the next reasonable step.

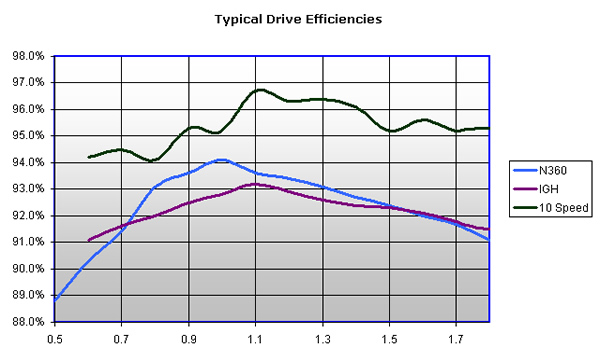

So, even with a, say, 5% lower average transmission efficiency than a derailleur system (with the average efficiency of a good derailleur being around 95.5%, the above 5% appears too much), a PatBox CVT can still provide a better “overall efficiency” to the average bicycler.

Another significant issue is the cost.

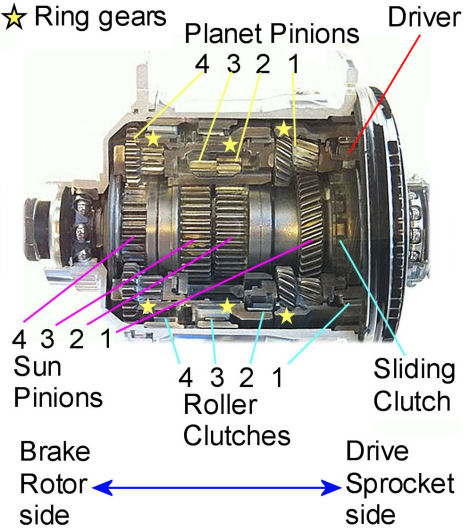

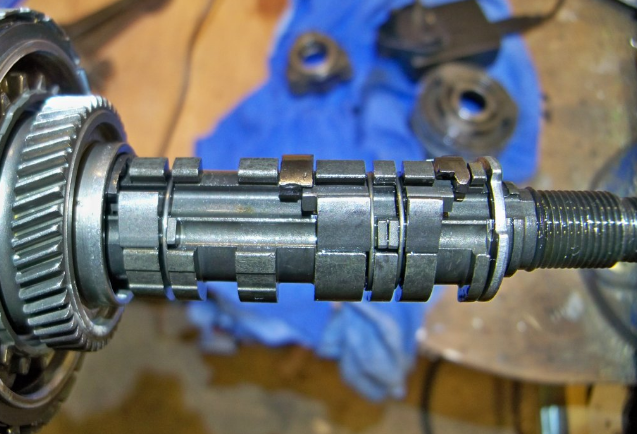

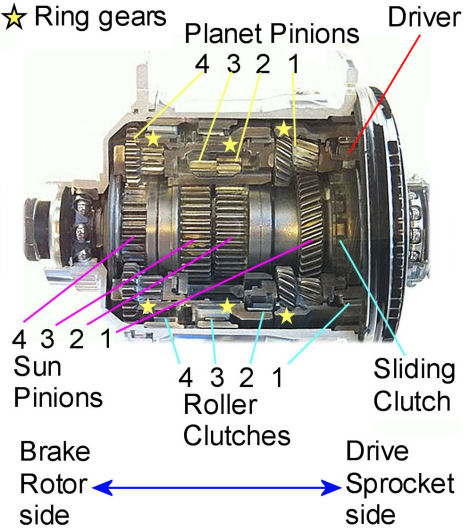

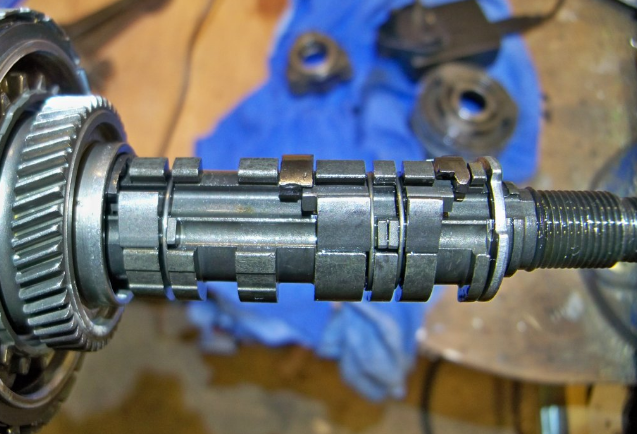

Here is the Alfine IGH of Shimano (which is not a CVT) :

Its complication (just imagine the work the shaft in the lower photo needs) justifies the 400, or so, Euros of its price (no matter how strange it appears a bicycle having a HUB gearbox costing 400 Euros!)

And what it offers? Just 11 gear ratios, and an average efficiency of some 92%.

In comparison,

I don’t see a reason for a PatBox CVT bicycle (having an infinity of easily selectable gear ratios) to be (in mass production) more expensive than a similar conventional bicycle.

Thanks

Manolis Pattakos