You write:

“..... and now ponder how to emulate a scooter CVT transmitting circa 5lbs.ft of torque with a 200lb cyclist generating 100lbs.ft torque without the belt slipping. Manipulate the force required for that from the handlebar? It'd be worse than tensioning a truck's fan belt - while simultaneously riding a bike.”

I don’t know what you mean by “tensioning a truck's fan belt”.

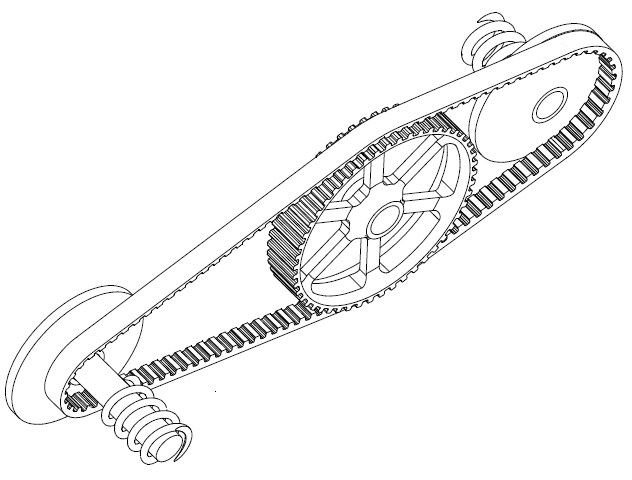

So, let’s make a rough calculation to find out how hard it is to shift to another gear ratio with the lever of the PatBox in a bicycle.

Suppose the coefficient of friction between the elastic V-belt and the conical pulley halves equals to 1.

Suppose a 100Kp (220lb) bicycler weight.

Suppose a 150mm (0.5ft) pedal crank-arm.

Suppose a 75mm (0.25ft) maximum radius of the V-belt running on the rear pulley, and a 1:1 minimum transmission ratio.

150mm/75mm=2

So, the rear pulley, at the shortest gear ratio (i.e. at the ratio the bicycle starts moving), has to apply a force of 2*100=200Kp (440lb) on the V-belt, so it is required a clamping force of 100Kp (220lb); (because force is applied on both sides of the V-belt).

In order the auxiliary belt to displace the V-belt deeper in the rear pulley, it is required to apply to the V-belt a force of 100/4=25Kp (55lb): this is due to the wedge effect and to the angle of the conical pulley halves (say 28 degrees, tan(28/2)=0.25=1/4).

The auxiliary belt has two spans, one above and another below the V-belt. So, each span of the auxiliary belt has to be loaded by a force of 25/2=12.5Kp (28lb).

This is the force the movable roller-tensioner has to apply to the auxiliary belt horizontally.

The handle (the top) of the lever is at a 3.5:1, or so, “leverage” relative to the upper roller-tensioner, which means, the hand of the bicycler has to apply on the lever a force of 12.5/3.5 = 3.5Kp (8lb), i.e. as much as a lightweight domestic cat weighs (from the Internet: according to APOP, a domestic cat should be about 8-10 lbs (3.6-4.5 kg)).

The previous rough calculations give an idea for the magnitude of the required force on the lever.

And it seems OK not only for the average bicycler, but also for the extra lightweight bicyclers.

The arrangement of the PatBox lever may seem strange and unconventional to the familiar with the derailleur / IGH / NuVinci bicycle gear-trains and control.

However for the new bicyclers, and for the bicyclers who dislike, or never got how to use efficiently, the conventional bicycle gear-train and control, the lever of the PatBox appears quite more physical and simple and understandable.

The following instructions for the use of the PatBox:

“When your legs are pedaling too fast push the lever forwards, and when your legs are pedaling too slow pull the lever backwards.”

is all a bicycler needs to know.

Thanks

Manolis Pattakos