You write:

“reducing transmission power loss by eg 10% of engine power ......

will only reduce fuel consumption by 10% if bte does not fall with the corresponding reduction in engine power demanded

bte will fall with reduced power due to increased throttling

and eg if bte falls by 10% of 'original' bte then there will be no fuel consumption benefit (likely with high power engines)”

On this reasoning, we should put a “disk brake” on the one pulley of the CVT to add lots of friction which will enforce the engine to operate permanently at wide open throttle, and so higher efficiency.

Or, think it differently:

Saving the 10% of the power of the engine which is consumed as friction in the CVT, a 10% smaller engine can be used: same performance, 10% higher mileage.

Or think it more differently:

The PatEf CVT with 10% lower friction can be tuned to keep the engine at lower revs, wherein for the same power it is required more open throttle.

The basic characteristic of the CVT’s is their automatic operation.

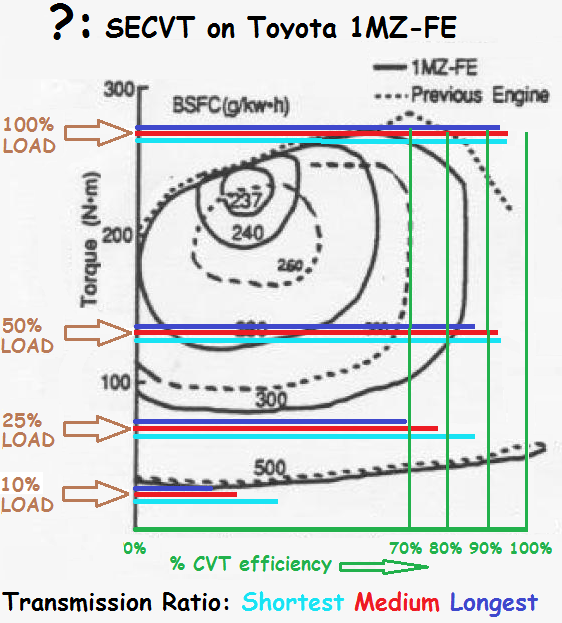

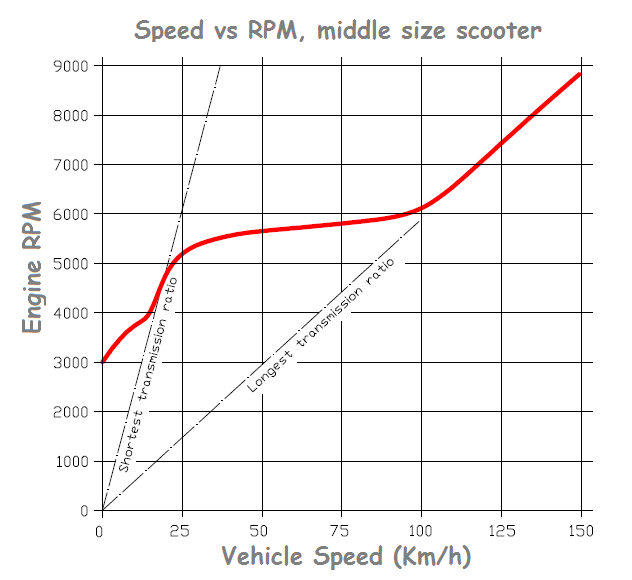

Another characteristic is their ability to keep the engine at the desirable revs for a wide range of vehicle speeds:

which is not possible with the conventional gear boxes:

Another characteristic is the smooth “gear-shifting” (the guy who made the first PatBox prototype wrote, when he first tested it: it shifts like butter).

Another characteristic is the continuous change of the transmission ratio from the shortest to the longest allowable value.

Another characteristic of the scooter and sled V-belt CVT’s is that they are “uncontrolled”.

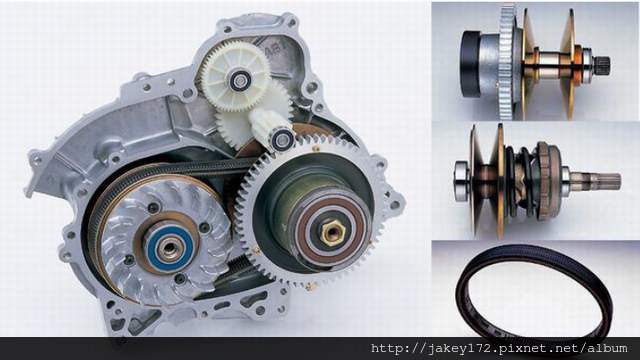

The SECVT of Suzuki:

the PatBox CVT:

and the PatCVT:

offer control (automatic or manual) over the transmission ratio of the CVT, keeping at the same time its “full automatic” characteristic when the driver / rider likes so.

Another characteristic of the scooter / sled CVT’s is the excessive fiction loss due to the over-clamping of the V-belt, which reduces the mileage and worsen the performance (a motorcycle having the same engine and the same weight with a scooter, is faster, has higher top speed and consumes less fuel).

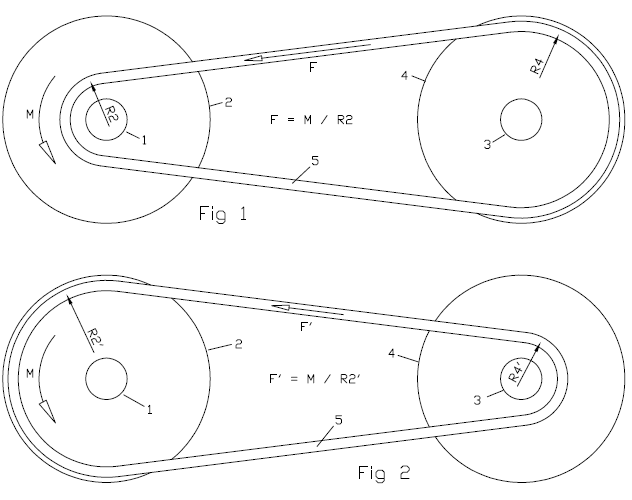

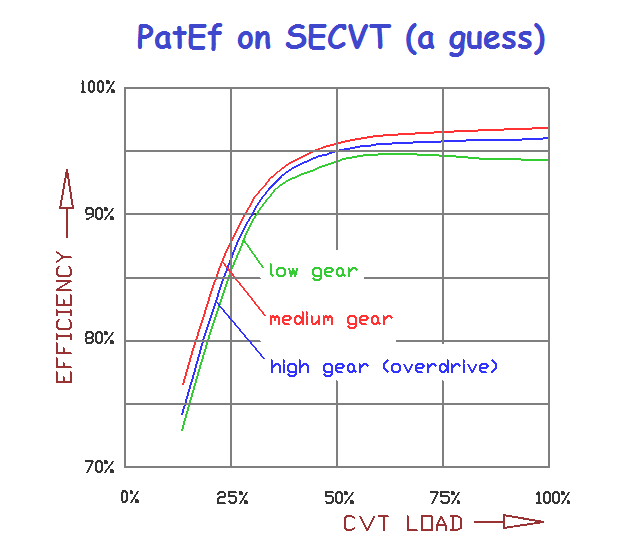

The PatEf:

is a simple way to reduce substantially the friction and use the power of the engine for pushing the vehicle forwards and not for overheating the CVT compartment and for wearing the drive belt.

Reasonably,

a “controllable” (PatBox?) automatic CVT having the same efficiency (PatEf) with the manual gear-boxes:

seems preferable for most applications (motorcycles, small cars, scooters, sleds, ATV’s, bicycles etc).

***Worth to note: the % load in the above plot refers to the CVT and not to the engine.

You also write:

"I now wonder (having found a lot of interesting but rather user-oriented info) .....

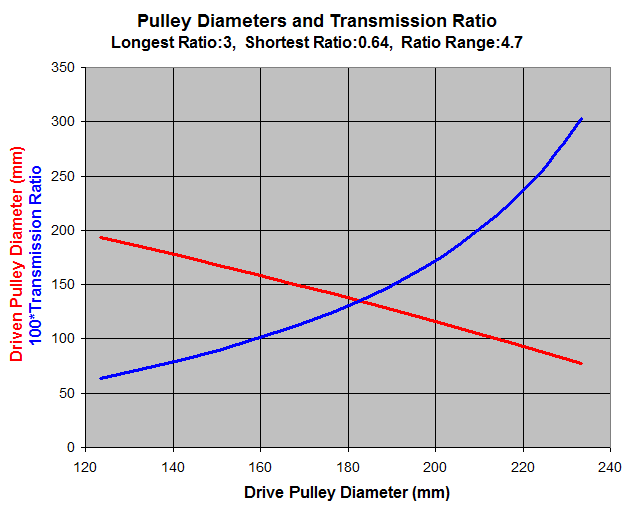

what max gear ratio % do 2-wheeler CVTs actually use ?

what reduction in over-clamping is obtained from mechanical torque-sensitive driven pulleys ?"

These data, and many more, can be found in the http://www.pattakon.com/PatBox/SECVT.pdf

Thanks

Manolis Pattakos