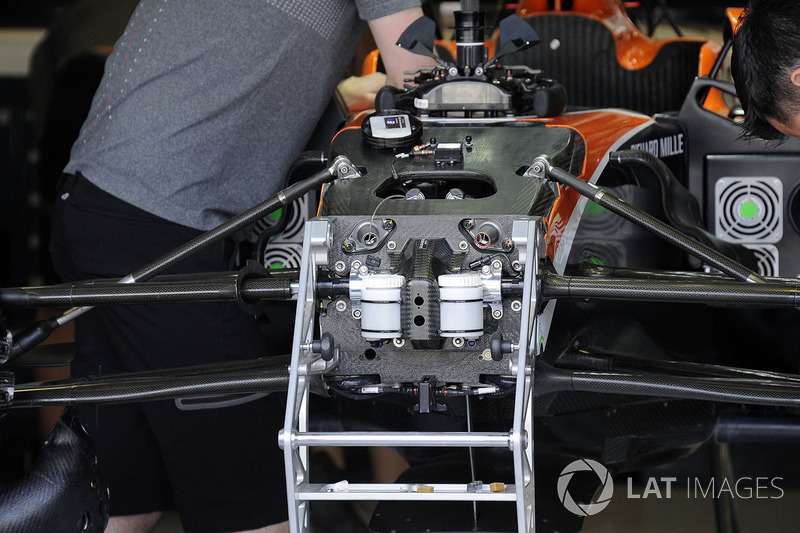

Nice angle

Not helped by the fact that the MCL32's suspension components are well hidden even with the bodywork off.godlameroso wrote: ↑28 Oct 2017, 23:08The suspension components is the area we've seen the least of. I haven't even seen so much as a rocker arm this year.

Well, let me start with the conspirancy theories. What does Mclaren have to hide hmm?roon wrote: ↑29 Oct 2017, 22:57Not helped by the fact that the MCL32's suspension components are well hidden even with the bodywork off.godlameroso wrote: ↑28 Oct 2017, 23:08The suspension components is the area we've seen the least of. I haven't even seen so much as a rocker arm this year.

https://cdn-3.motorsport.com/images/mgl ... detail.jpg

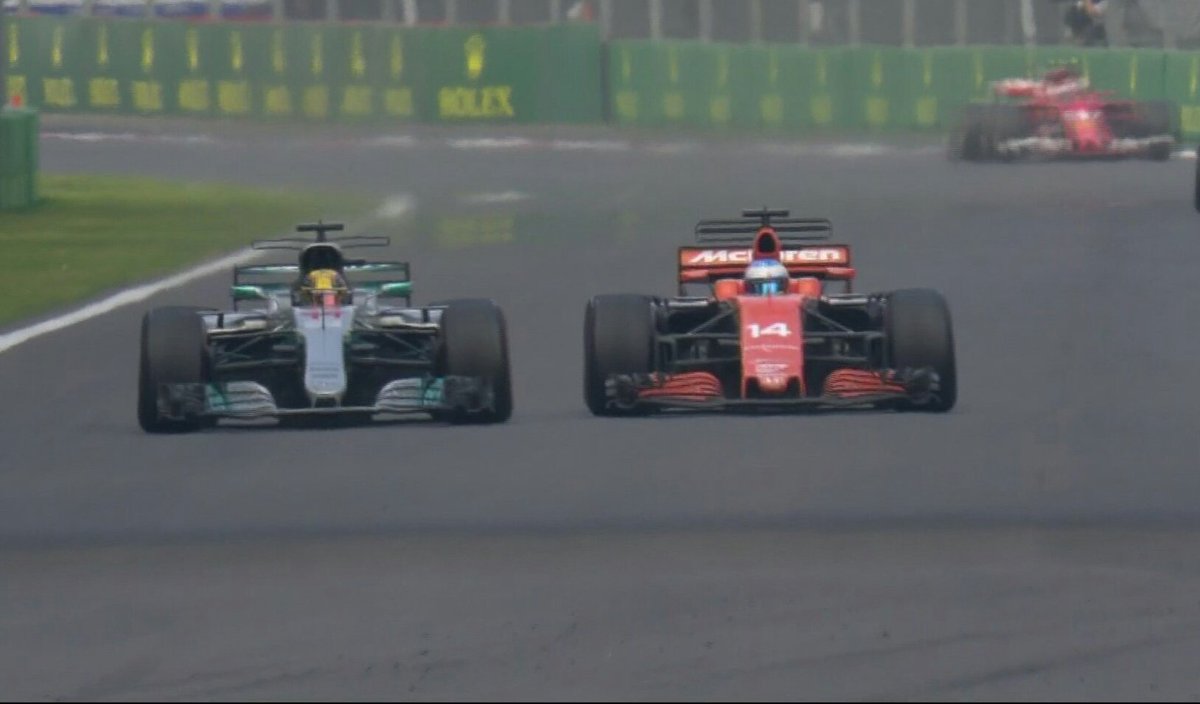

Interesting detail, and yes, it is one of the benefits of high rake.f1rules wrote: ↑30 Oct 2017, 09:17From Joseki autosport forum

Its interesting to see how much closer to the ground mclarens frontwing is, probably due to the high rake philosophy

https://pbs.twimg.com/media/DNVlxJmW0AIjPXZ.jpg

This is the first time I've seen 9 wing elements at the Y250 section.mclaren111 wrote: ↑29 Oct 2017, 11:48https://cdn-8.motorsport.com/images/mgl ... -mcl32.jpg

Nice angle

#aerogollumturbof1 wrote: YOU SHALL NOT......STALLLLL!!!

I haven't. I've been an aficionado of counting the number of elements at a given wing section (obscure but true!), and until recently I've only seen up to 7. The McLaren Y250 wing section always looked more thin and precise than other cars all season long (even back when they only had 7 elements there), so I think they must 3D print that area.

You are right in the sense that ideally they don't want to weaken the vortex. But in the same sense they don't want a vortex that stops existing under braking because of the pitch. So these slots will introduce air under the wing, which essentially prevent 'choking'. They allow the vortex to more consistently exist. Downforce will be more consistent, but peak downforce would be a little lower.BloodLad91 wrote: ↑26 Oct 2017, 17:00I read article by technicleformula1 and your right the update weakens vortex, couldn't understand why any team would do that since all i hear how important it is, sorry about previous comments i'm not well versed in f1 aero, so don't take my comment too seriously.

i think u conflate the importance of the vortex with the need of fueling it.wesley123 wrote: ↑02 Nov 2017, 17:58You are right in the sense that ideally they don't want to weaken the vortex. But in the same sense they don't want a vortex that stops existing under braking because of the pitch. So these slots will introduce air under the wing, which essentially prevent 'choking'. They allow the vortex to more consistently exist. Downforce will be more consistent, but peak downforce would be a little lower.BloodLad91 wrote: ↑26 Oct 2017, 17:00I read article by technicleformula1 and your right the update weakens vortex, couldn't understand why any team would do that since all i hear how important it is, sorry about previous comments i'm not well versed in f1 aero, so don't take my comment too seriously.

It seems like they have bigger gaps between the elements as well, something I've noticed from them during the McLaren-Honda era, and distinct from the rest of the field.

It'll be in carbonfibre, I think. Just well-made.roon wrote: ↑02 Nov 2017, 23:01It seems like they have bigger gaps between the elements as well, something I've noticed from them during the McLaren-Honda era, and distinct from the rest of the field.

If not 3D printed, they may just have developed more streamlined processes for turning around CF parts. Something the whole field seems more adept at nowadays. The tiny features like the brake duct winglets, diffuser feathers and VGs, for the most part still show CF weave.

3D printing of Rapid prototyping is very heavy and weak compared to CF. It's not very used in racecar except test parts or very experimental devices just to see if it's worth producingCraigy wrote: ↑09 Nov 2017, 16:58It'll be in carbonfibre, I think. Just well-made.roon wrote: ↑02 Nov 2017, 23:01It seems like they have bigger gaps between the elements as well, something I've noticed from them during the McLaren-Honda era, and distinct from the rest of the field.

If not 3D printed, they may just have developed more streamlined processes for turning around CF parts. Something the whole field seems more adept at nowadays. The tiny features like the brake duct winglets, diffuser feathers and VGs, for the most part still show CF weave.

The 3d printing I've seen in F1 (plastics) is for 60% scale aero models generally.

In F1 some bits are created using SLS (metal additive "printing") - but you'd not use that for front wing elements.