You write:

“As for the rotary drum inlet (that is what we are looking at) its opening and closing is too slow as compared to a large dia rotary disc valve inlet. Rotary drums were abandoned in the 1930's, “

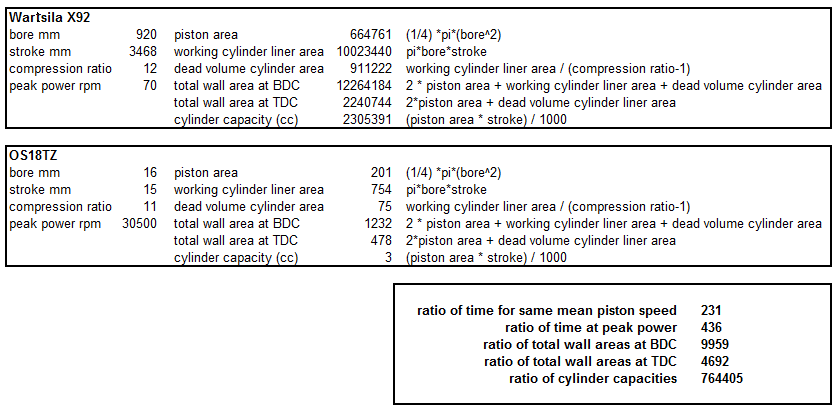

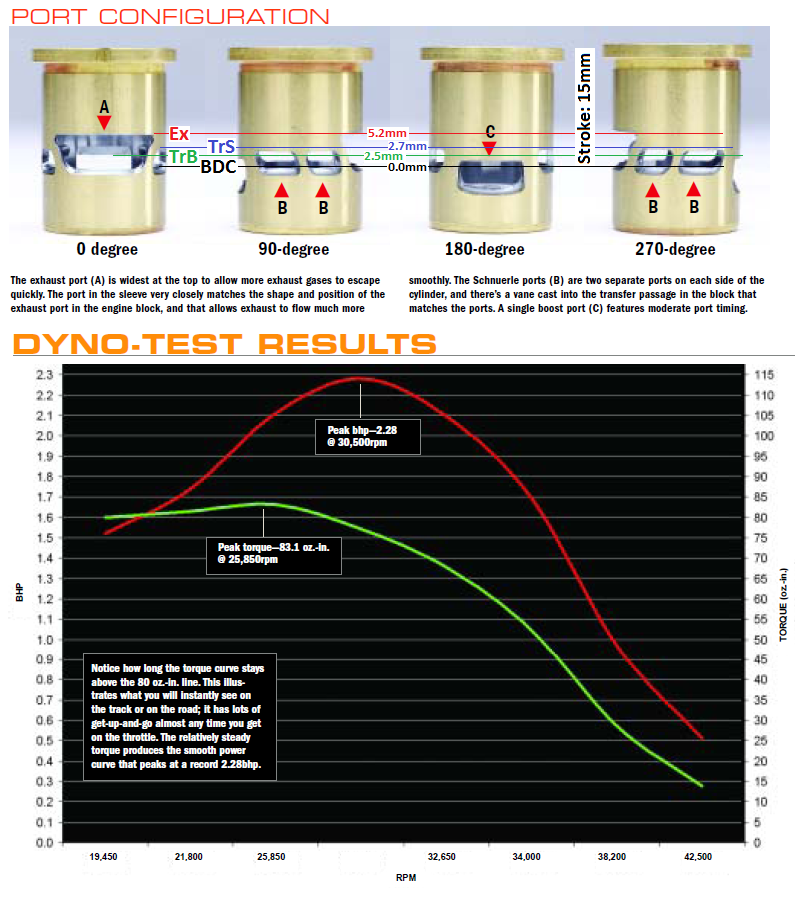

The OS18TZ is a 2-stroke model engine having:

16mm bore,

15mm stroke,

3.02cc displacement,

2.28bhp peak power @ 30,500rpm (755bhp/lit)

80oz-in torque from 19,000rpm to 29,000rpm

(0.58mN from 19,000rpm to 29,000rpm)

(more at http://www.pattakon.com/tempman/osmz211 ... cnitro.pdf )

The specific torque, along the 19,000rpm to 29,000rpm rev range, is above: 0.58mN/0.00302lit = 192mN/lit = 19mKp/lit

The specific torque is double than that of the good 4-stroke sport engines.

More interesting: this top specific torque is maintained along a long rev range (not tuned): from 19,000rpm to 29,000rpm; like, say, having a completely flat (and top, at the same time) torque from 5,000 to 8,000rpm in a normal size (~300cc per cylinder) 2-stroke.

The above model engine is based on a rotary drum inlet:

The diameter of the crankshaft at the drum valve is 12mm, with the diameter of the hole towards the crankcase being 7.5mm.

Note: this is for a bore of 16mm.

The above 12mm diameter is a compromise between the “fast opening –closing” of the inlet port and the need for a small diameter main crankshaft roller bearing.

From the above dyno it seems the drum inlet of the OS18TZ makes a better job (by the way, there is no reed valve capable to operate reliably at the 40,000+ rpm of the red line of this small engine).

In the PatATE the diameter of the drum valve is necessarily bigger than the bore. Instead of 12mm in the OS18TZ, it would be, say, 18mm (50% bigger) in a PatATE-OS18TZ.

This would give a substantially faster inlet opening and inlet closing, if necessary.

Unless I am wrong:

without a power valve,

and with a torque which is not only top, but it is also flat along a wide rev range,

a tuned exhaust would be more a problem than a solution.

The PatATE introduces some new "strong" parameters in the 2-stroke architecture for greener,and at the same time more powerful, 2-strokes.

Thanks

Manolis Pattakos