Hello J.A.W.

The patent application publication of (Rotax?) – BRP is not yet searched / examine (it is not yet a patent; it may be).

First claim:

“1. A method for controlling a two-stroke internal combustion engine, the engine having at least one combustion chamber, at least one direct fuel injector for injecting fuel directly in the at least one combustion chamber, and at least one port fuel injector for injecting fuel upstream of the at least one combustion chamber, the method comprising: determining a first fuel quantity to be supplied to the at least one combustion chamber; determining a ratio of the first fuel quantity to be injected by the at least one direct fuel injector; determining a ratio of the first fuel quantity to be injected by the at least one port fuel injector; injecting a second fuel quantity in the at least one combustion chamber using the at least one direct fuel injector; injecting a third fuel quantity upstream of the at least one combustion chamber using the at least one port fuel injector, a sum of the second and third fuel quantities being initially greater than the first fuel quantity; and decreasing at least one of the second and third fuel quantities over time such that the sum of the second and third fuel quantities equals at least the first fuel quantity.”

I seems to me that the Examiner can easily reject it for lack of inventive step, because for the “skilled in the art” this method is obvious / reasonable.

Besides, if someone wants to bypass this “method”, he can use injection maps by means of which,

depending on the instant operational conditions (air temp, ambient pressure, lambda sensor, water temperature, etc) and on the “mode” selected (sport, drive, economy, etc),

the ECU decides how much fuel to inject “directly” into the cylinder, and how much fuel to inject “indirectly” in the port.

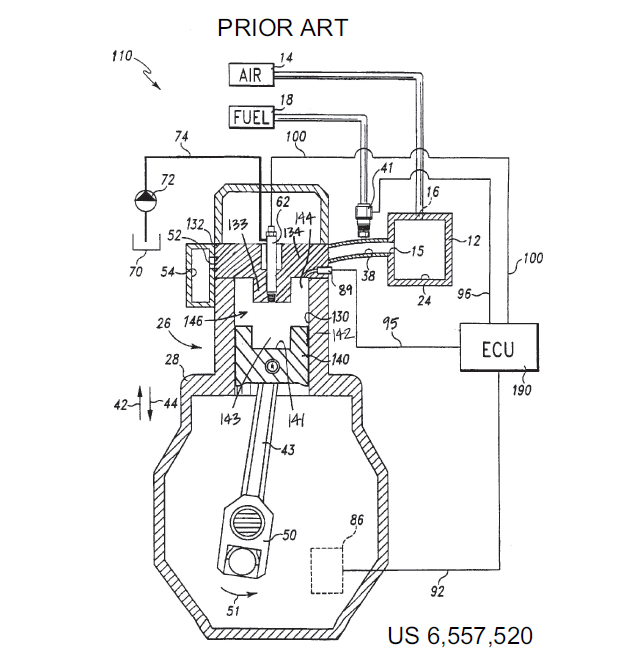

In any case, the most interesting part of this patent application seems the section wherein the BRP presents the weaknesses / limitations of their own direct injection E-TEC system:

“In recent years, the port fuel injectors have been replaced in some two-stroke engines by direct fuel injectors such as the E-TEC.TM. fuel injector from BRPTM. The direct fuel injectors inject fuel directly into the combustion chambers of the engine. As a result of the use of the direct fuel injectors, the engine performance has improved, even more precise control of the fuel quantity being injected is possible, less oil is used, and the amount of polluting emissions, such as carbon monoxide, has been reduced even more.

Although direct fuel injection has helped improved two-stroke engines, as the demand for even higher performance engines continues,

the use direct fuel injectors has some drawbacks. For example,

at very high engine speed (RPM), there is a very short period of time during which fuel can be injected and then mix with the air in the combustion chamber.

As such, the fuel may not have the time to properly atomized, resulting in larger droplets of fuel being combusted, which emits more soot than when the fuel has properly atomized.

Although some of the above drawbacks

could be resolved by switching to a four-stroke engine, (!!!) doing so would result in losing the advantages typically associated with two-stroke engine, namely a simplified construction, more power (two-stroke engines have an explosion in each combustion chamber at every revolution, four-stoke engines at every two revolutions), and a lighter weight. These advantages of two-stroke engines are important features for vehicles such as motorcycles, snowmobiles and other recreational vehicles.”

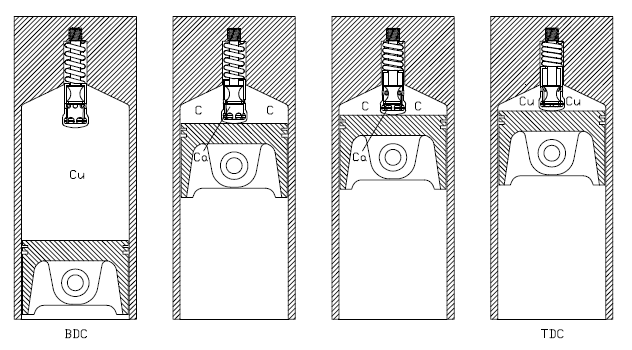

Regarding the PatBam control over the HCCI combustion in the 2-strokes (animation in the last post),

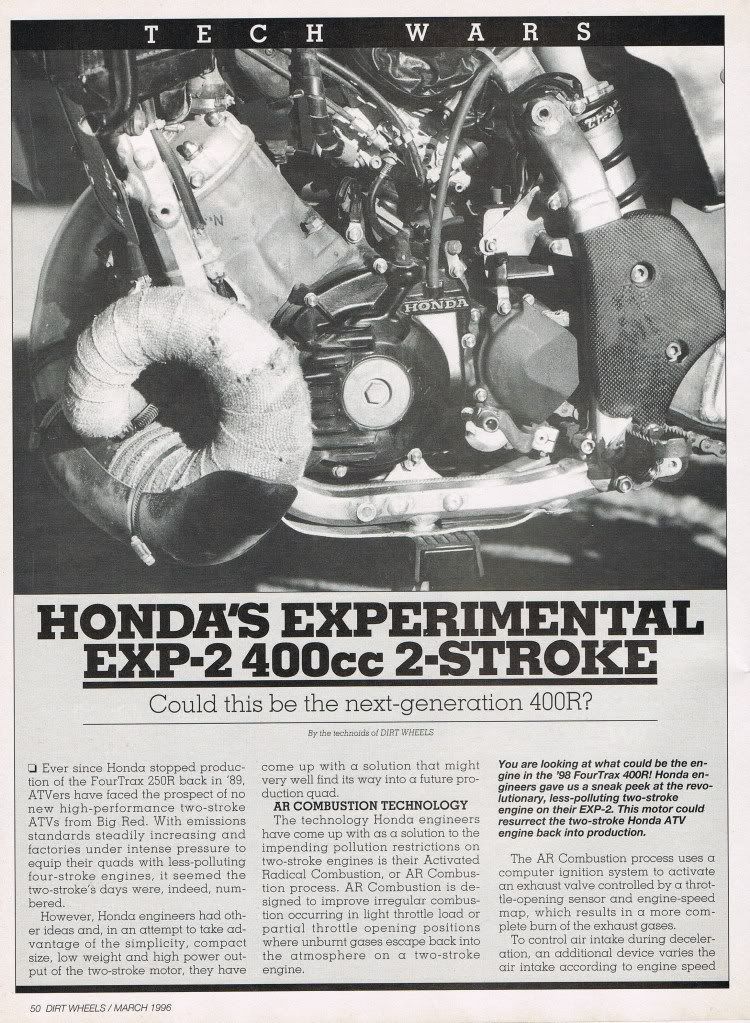

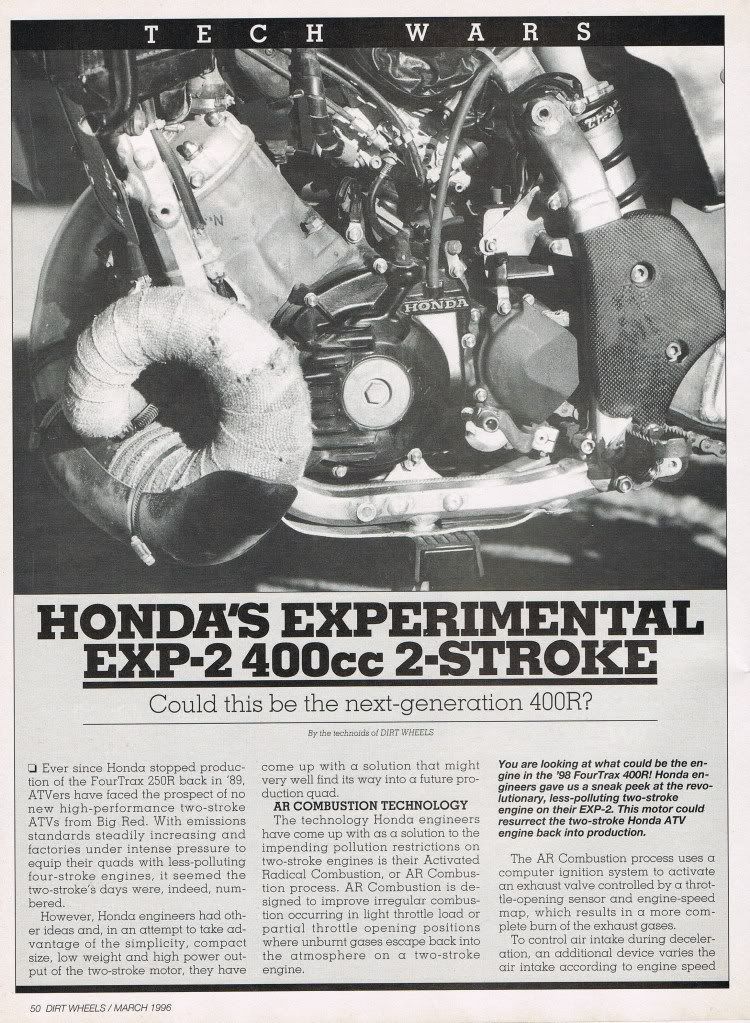

it is like the Honda EXP HCCI wherein the trapped exhaust gas provides the required “active” radicals for the ignition of the new charge

The radicals in the combustion chamber are like burning coal pieces:

thrown into a forest to put fire.

The active radicals, used in the Honda EXP for the ignition of the trapped fresh mixture, were created a crankshaft rotation earlier, during the last combustion.

After the combustion they were cooled and “exhausted” (during the expansion, exhaust, scavenging and compression).

Even “semi dead”, they do fire the fresh charge

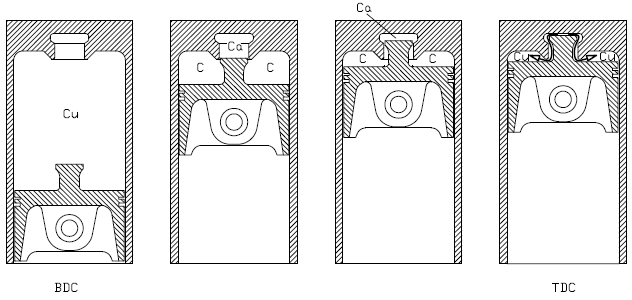

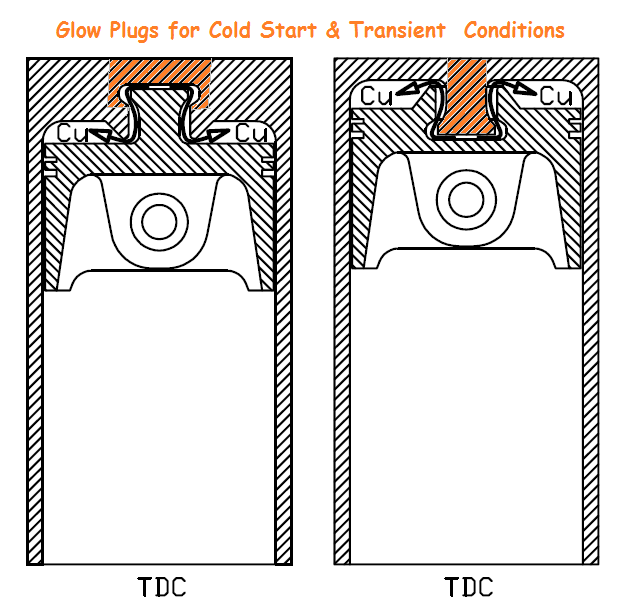

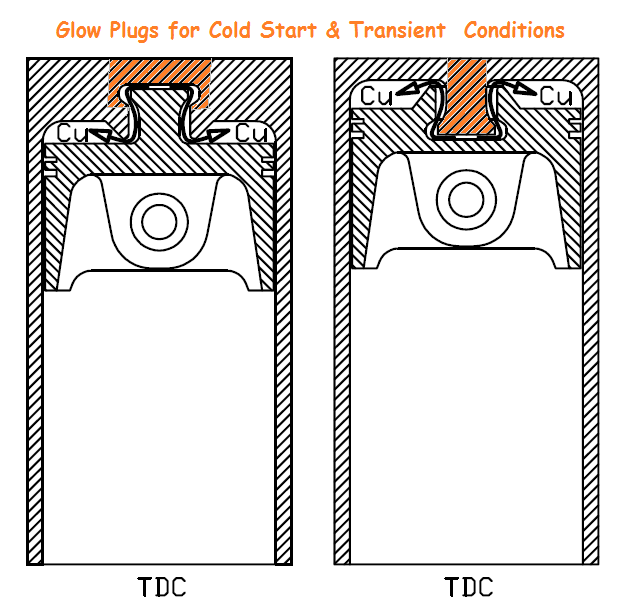

In the PatBam the radicals are created a few (say 10) degrees before the TDC in the auxiliary chamber and immediately after (still before, or at, the TDC) they bust into the compressed – hot air-fuel in the main chamber.

A characteristic of the PatBam is that the auxiliary chamber starts communicating with the main chamber just before the TDC, i.e. before any expansion in the pre-chamber (expansion means temperature drop).

Even if the HCCI combustion in the auxiliary chamber ends some 5 - 10 degrees before the opening of the “transfer ports”, after its combustion the burnt gas is further compressed; the compression tends to further rise the gas temperature, while the pre-chamber walls have not too much time to cool it down.

At the same time the mixture in the main chamber is further and further compressed, warmed and prepared to receive the active radicals from the auxiliary chamber just before the TDC.

The high pressure in the auxiliary chamber causes the penetration of the highly active radicals deep into the hot / compressed air-fuel mixture in the main chamber, triggering its HCCI combustion.

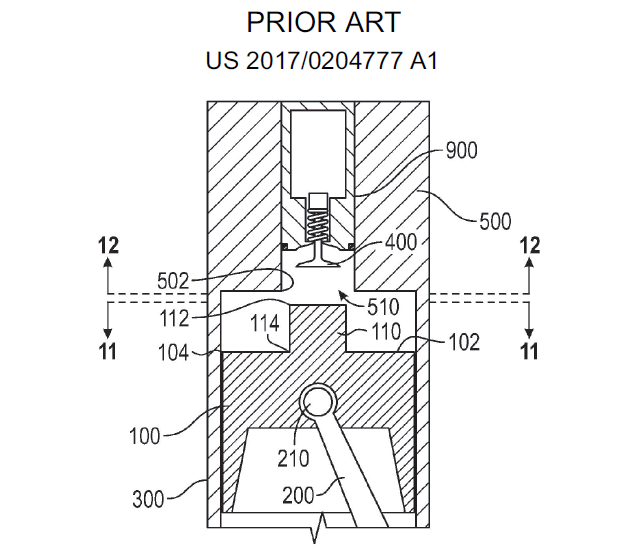

By comparison,

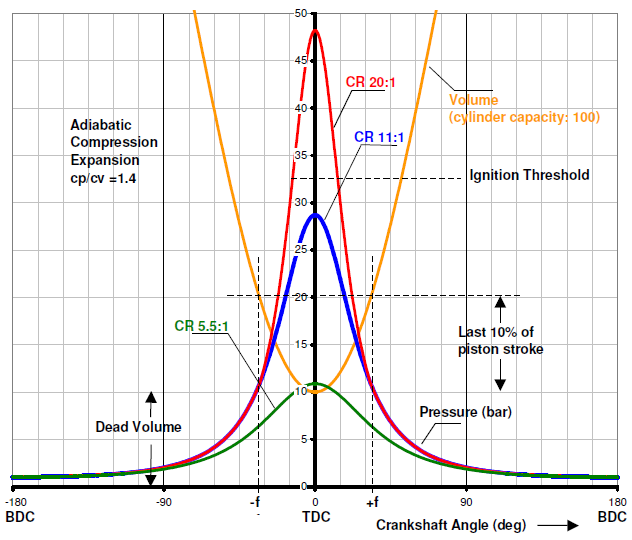

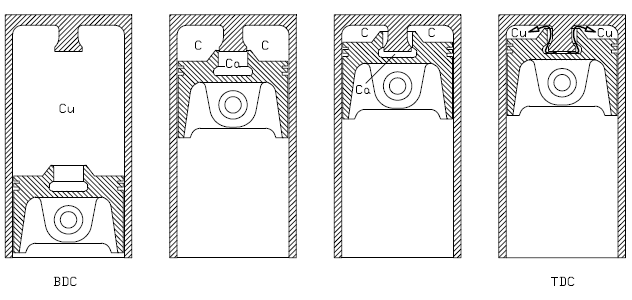

in the prior art (Chatterton, Roberts, Nautilus, etc) after its combustion in the pre-chamber, the burnt mixture undergoes a significant expansion: the volume in the pre-chamber over-doubles;

supposing adiabatic expansion in the pre-chamber, the absolute temperature of the burnt gas drops by more than 25% ((1/2)^0.4=0.75), say from 1700 degrees Celsius to only 1200 Celsius;

taking also into account the cooling affect of the surrounding pre-chamber walls (worth to mention here the longer time the gas stays in the pre-chamber after its combustion), when the two chambers eventually start communicating, the radicals are “semi-dead” (a big damage for the rest cycle) and the pressure is low reducing the penetration capability of the gas stream with the “semi-dead” radicals into the unburned mixture of the main chamber.

At the same time another “damage” is taking place in the main chamber wherein the compressed / warmed air-fuel mixture undergoes a significant expansion / cooling before the entry of the “radicals” from the pre-chamber: the temperature drop is more than significant; the absolute temperature of the air-fuel mixture in the main chamber drops by some 25% at the 33, or so, crankshaft degrees at which the two chambers unite (wherein the volume doubles with reference to the dead volume); a (main chamber) temperature drop from 630 deg Celsius at the TDC to only 400 deg Celsius when the two chambers start communicating makes the controllable HCCI difficult, if possible.

According the previous theory, with the PatBam things improve “square” relative to the prior art: way more active radicals penetrating way deeper into the main chamber wherein the conditions are way better for HCCI combustion.

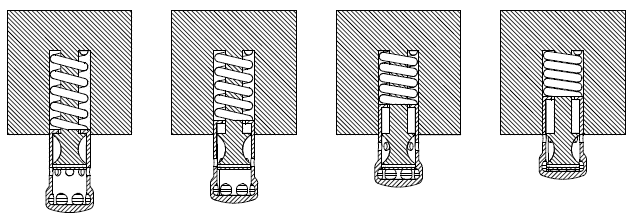

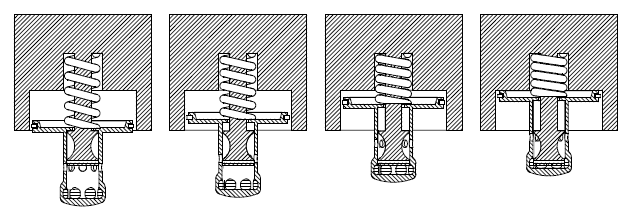

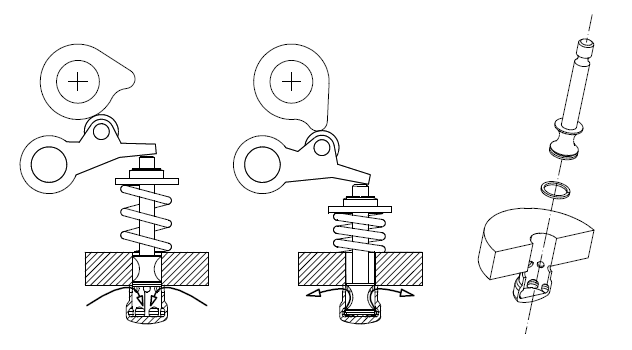

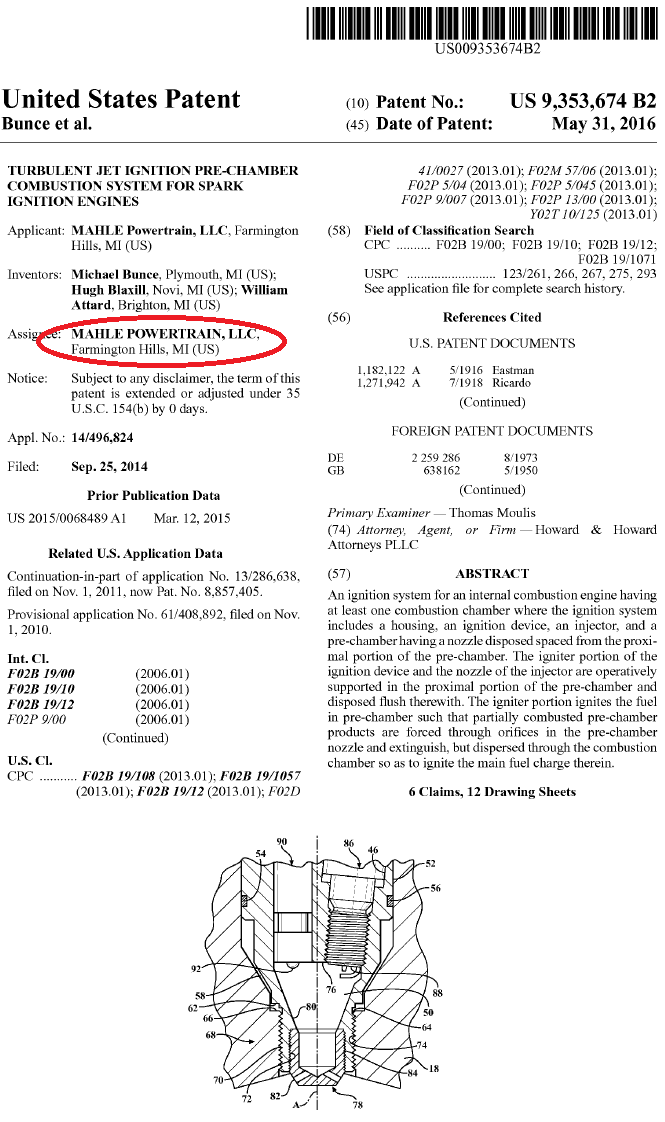

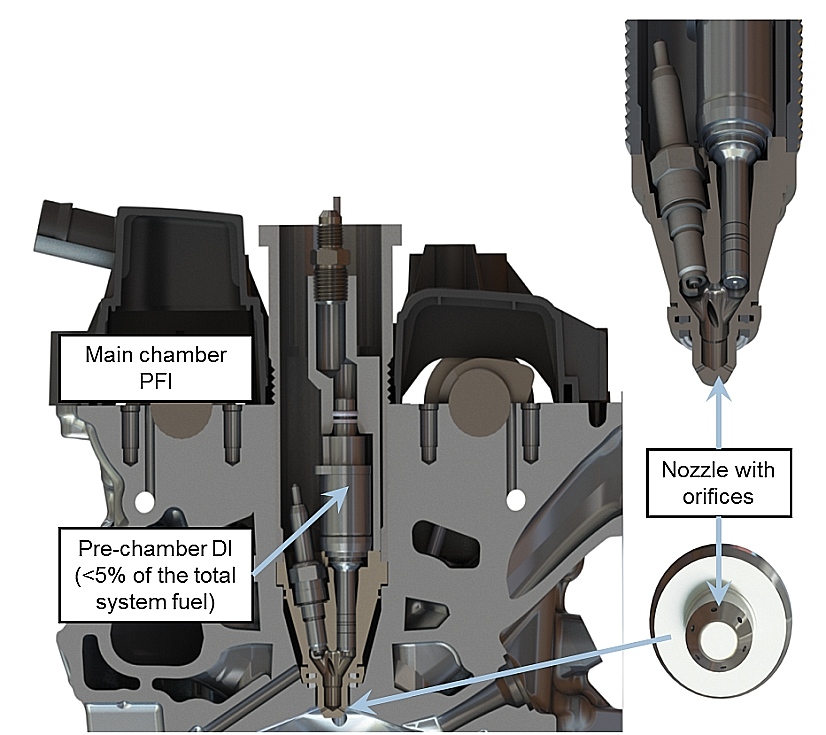

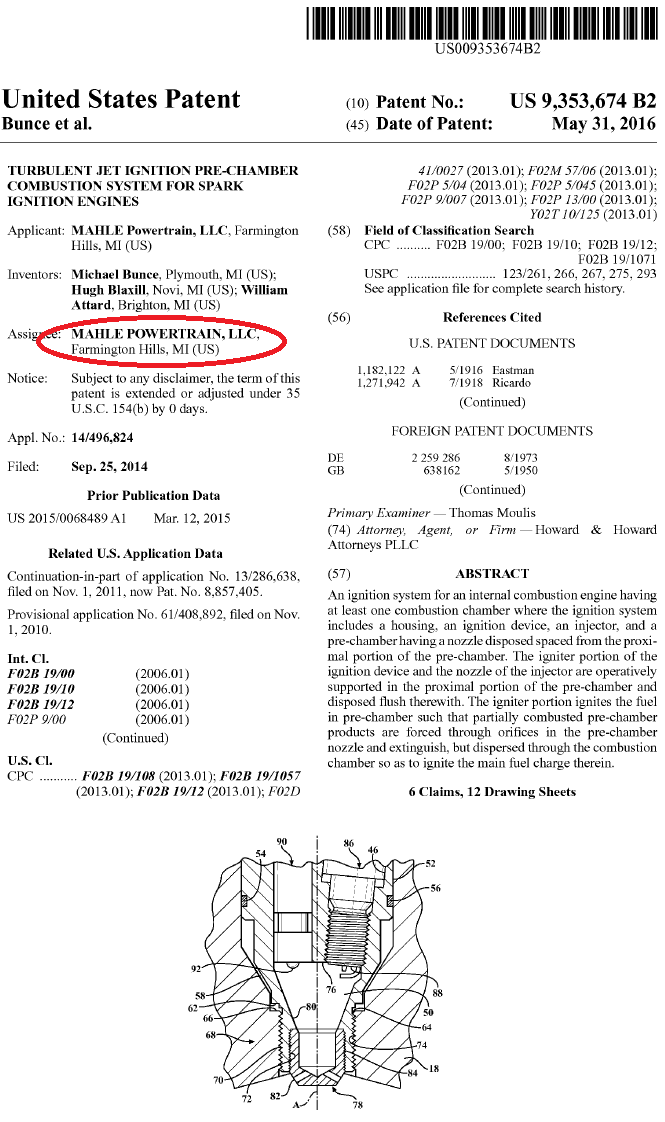

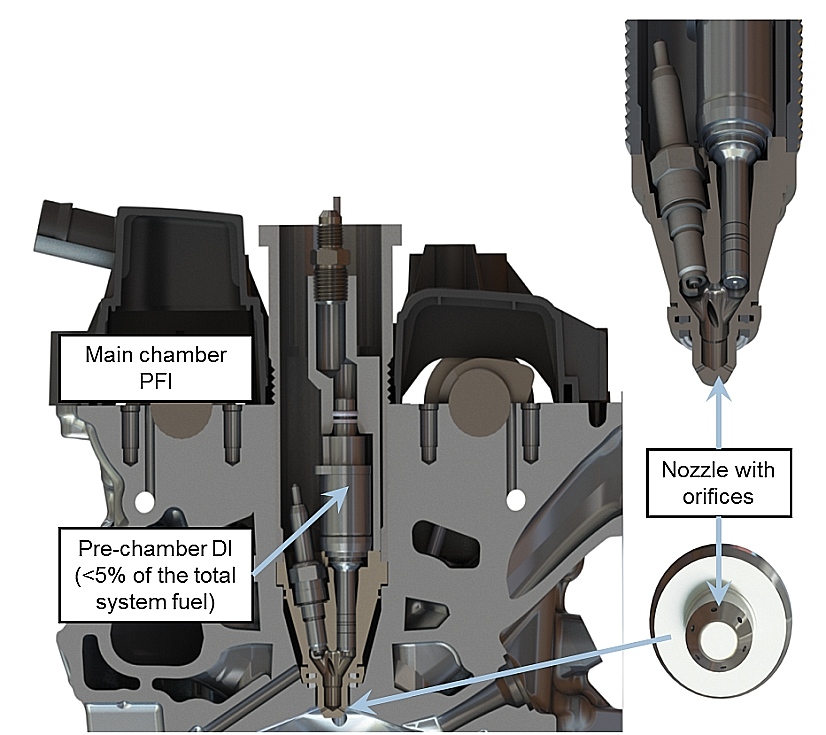

Here is the TJI of Mahle:

and here are some characteristics that distinguish the two systems from each-other, the Mahle TJI and the PatBam.

1.

The Mahle TJI requires a high pressure / high tech injector to directly inject a small quantity of fuel into the pre-camber.

The PatBam needs not direct injection. Not even an injection system. Even with a carburettor it would work, because it’s ignition is tolerant to the air-fuel ratio in a wide range.

Think of it as an add-on, that replaces the spark plugs of old carburetted engines and how much the emission would drop.

This makes the PatBam cheaper and simpler.

2.

The Mahle TJI requires a high voltage ignition system to put fire onto the “rich” air-fuel mixture in the pre-chamber.

The PatBam needs not a high voltage system, nor spark plugs. The high compression inside the pre-chamber causes the auto-ignition of the lean mixture therein (HCCI).

This makes the PatBam not only cheaper and simpler but also more reliable (think of an airplane engine wherein they use now two independent ignition systems and two spark plugs per cylinder, for safety).

3.

In the Mahle TJI pre-chamber, the combustion takes place at low pressure with the pre-chamber communicating permanently with the main chamber.

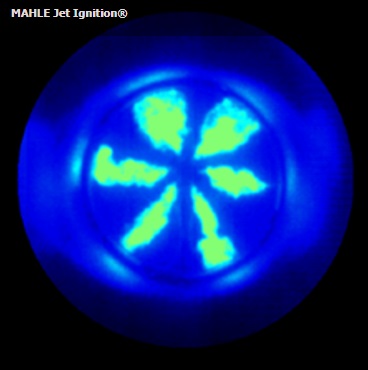

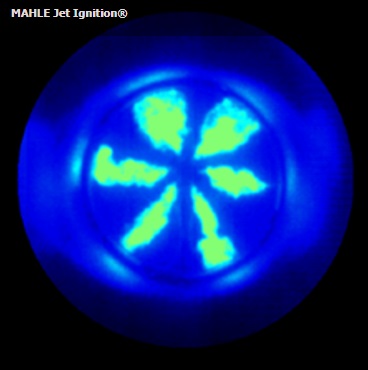

The spark plug ignites the rich mixture in the pre-chamber, and as the flame expands, it pushes a good part of the still un-burnt mixture from the pre-chamber, through the permanently open ports (orifices), into the compressed lean air-fuel mixture in the main chamber.

In the PatBam a little after the auto-ignition of the lean mixture inside the pre-chamber, the ports / orifices open.

The high pressure difference between the pre-chamber and the main chamber causes an explosive discharge / penetration of the burnt gas from the pre-chamber into the compressed air-fuel mixture in the main chamber (in a way similar to the direct injection Diesels wherein the penetration of the fuel is achieved with some 2,000 bar injection pressure for liquid injection).

The active radicals penetrate “instantly” (in comparison to Mahle’s TJI) in the compressed air-fuel mixture, which also undergoes a pressure sock.

All these trigger the HCCI combustion of the rest mixture.

I.e. in the one case (Mahle TJI) burnt gas is blown into the compressed air-fuel mixture in the main combustion chamber providing a faster and more stable combustion of the lean mixture, while in the other case (PatBam) the conditions favour true HCCI combustion not only in the pre-chamber, but into the main chamber as well.

Thanks

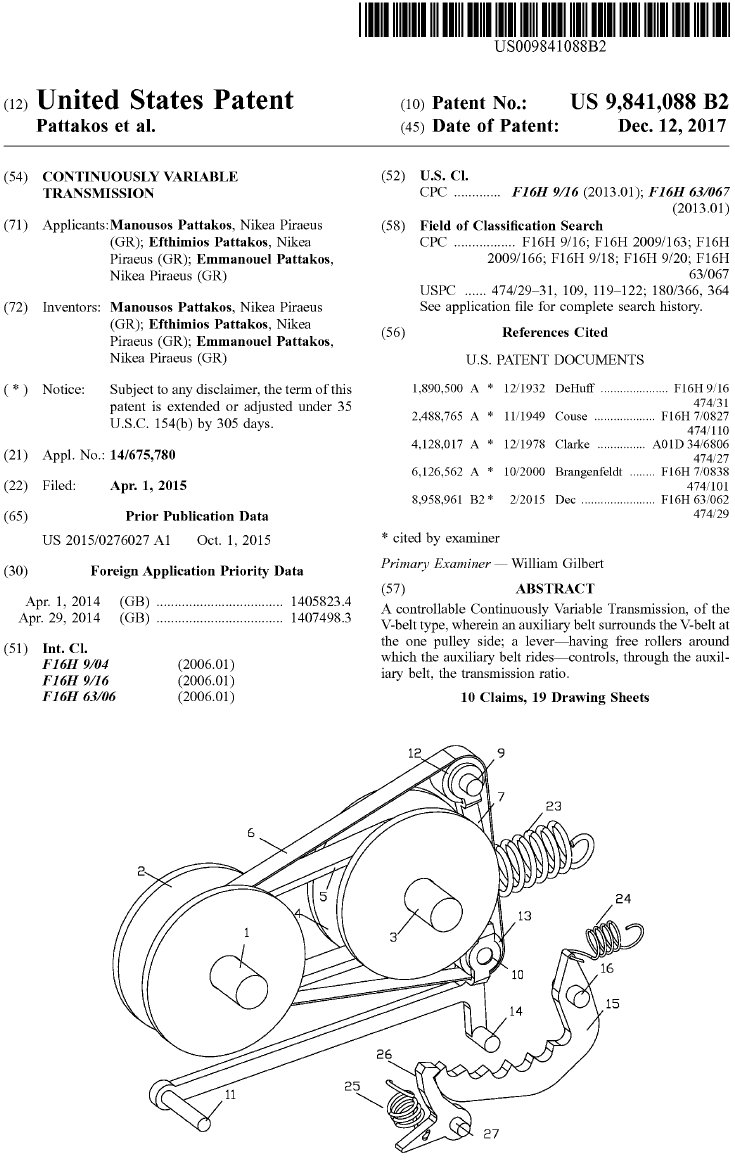

Manolis Pattakos