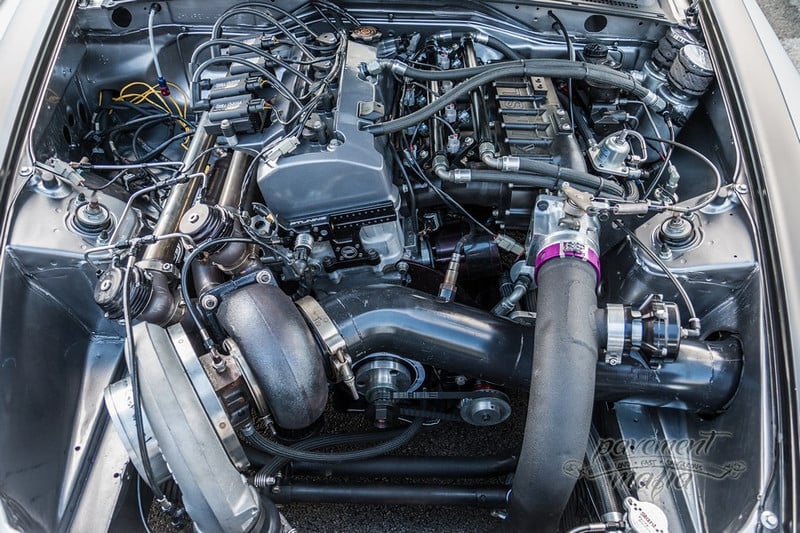

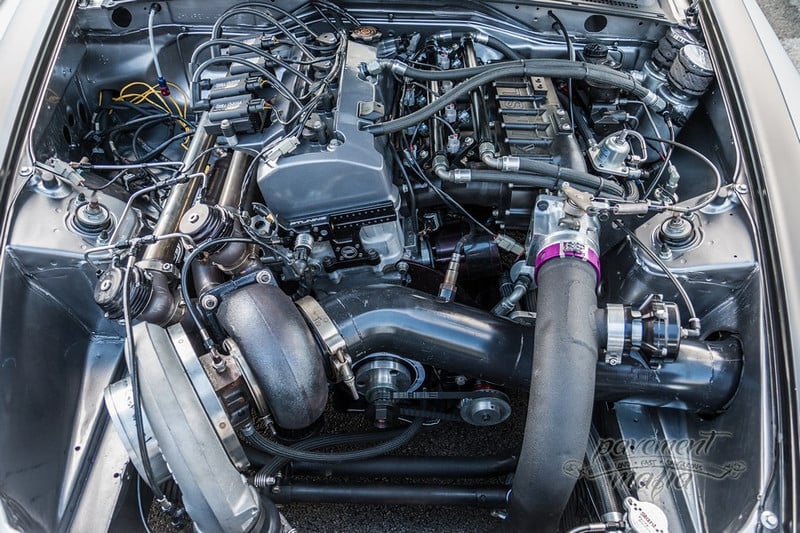

Compare this to pictures of the turbos on these F1 cars, and minus the MGU-H they're more or less the same capacity.

I guess restricted fuel,fuel flow and weight might be the answergodlameroso wrote: ↑18 Dec 2017, 19:04What strikes me as odd is that the turbos on these F1 power units are things you see on 1,300hp+ cars, yet the F1 ICE can't produce more than 850hp on it's best day. It would imply that these ICE's are running as high as 21:1 AFR's which is unbelievable.

Compare this to pictures of the turbos on these F1 cars, and minus the MGU-H they're more or less the same capacity.

http://www.speednik.com/files/2014/11/a ... st-et1.jpg

How far can these 1,300hp+ cars go with the amount of fuel that a F1 car uses in a race of 300km?godlameroso wrote:What strikes me as odd is that the turbos on these F1 power units are things you see on 1,300hp+ cars, yet the F1 ICE can't produce more than 850hp on it's best day. It would imply that these ICE's are running as high as 21:1 AFR's which is unbelievable.

Compare this to pictures of the turbos on these F1 cars, and minus the MGU-H they're more or less the same capacity.

Considering this car has two stage fuel injection and 2,500cc's worth of fuel injection per cylinder, compared to ~900cc max in F1, I'd say F1 uses ~40% the fuel. Which isn't bad since you're making 300hp less using just over a 1/3rd of the fuel. It's actually pretty crazy when you see it in numbers you understand.JonoNic wrote: ↑18 Dec 2017, 20:07How far can these 1,300hp+ cars go with the amount of fuel that a F1 car uses in a race of 300km?godlameroso wrote:What strikes me as odd is that the turbos on these F1 power units are things you see on 1,300hp+ cars, yet the F1 ICE can't produce more than 850hp on it's best day. It would imply that these ICE's are running as high as 21:1 AFR's which is unbelievable.

Compare this to pictures of the turbos on these F1 cars, and minus the MGU-H they're more or less the same capacity.

http://www.speednik.com/files/2014/11/a ... st-et1.jpg

I think everyone agrees by now that running so lean is key for this era of Formula1 power units.PlatinumZealot wrote: ↑19 Dec 2017, 04:14The point of his post is that the size of turbocharger on the drag car above is made to flow enough air for 1300hp. That size is also similar to what is used in F1 except F1 cars only make around 850hp from the ICE. Therefore stoichiometric air for 1300hp / fuel for 850hp equals 1.5 times the stoic air fuel ratio. So 1.5 x 14 or thereabouts equals 21.

Given that the whole thing is made in the UK I don't get the "germany" reference. Please do explain.

I forgot that the engine is made in UK brixwotrh, it just stereotype being german manufacturer for me. Yeah, just wondering why in common sense machining is always better than casting.

There are many reasons why you would use machined billet parts over cast.

Do the F1 manufacturers not follow what BMW did with their 2.4l V8?MrPotatoHead wrote: ↑19 Dec 2017, 15:15There are many reasons why you would use machined billet parts over cast.

The first of which is that a machined piece is normally stronger than its cast counterpart, especially important in a fully stressed engine component.

Secondly casting is expensive to setup and time consuming - it's more for large production parts than short run parts.

But I'm betting the cylinder head on the Mercedes engines are not machined and are cast along with the engine block.

It's incredibly difficult to machine a billet head or block with coolant passageways as intricate as on an F1 engine.

Everything I engineer on F1 cars is made from billet.

No not really because of the incredible difficulty of machining the valve seat pockets, seats and combustion chamber that comes with doing it this way.Zynerji wrote: ↑19 Dec 2017, 15:35Do the F1 manufacturers not follow what BMW did with their 2.4l V8?MrPotatoHead wrote: ↑19 Dec 2017, 15:15There are many reasons why you would use machined billet parts over cast.

The first of which is that a machined piece is normally stronger than its cast counterpart, especially important in a fully stressed engine component.

Secondly casting is expensive to setup and time consuming - it's more for large production parts than short run parts.

But I'm betting the cylinder head on the Mercedes engines are not machined and are cast along with the engine block.

It's incredibly difficult to machine a billet head or block with coolant passageways as intricate as on an F1 engine.

Everything I engineer on F1 cars is made from billet.

They cast the head and cylinder block as a single unit to get rid of the head gasket weakness... after reading the BMW whitepaper by Theissen, I figured all manufacturers would follow suit...