roon wrote: ↑27 Dec 2017, 05:18

Correct, but still hard mounted to the chassis and gearbox, moving with them. What I meant to imply was: float the engine on compliant/active mounts as in production cars.

If you're looking for a set of mounting rubbers you will probably not find them. My guess is that with the high g-forces and high torque, you don't want the engine to sway around in every braking/acceleration zone or corner.

What your probably looking for is directional stiffness. You just want enough compliance in certain directions to be able to isolate some movements or vibrations. That means metal.

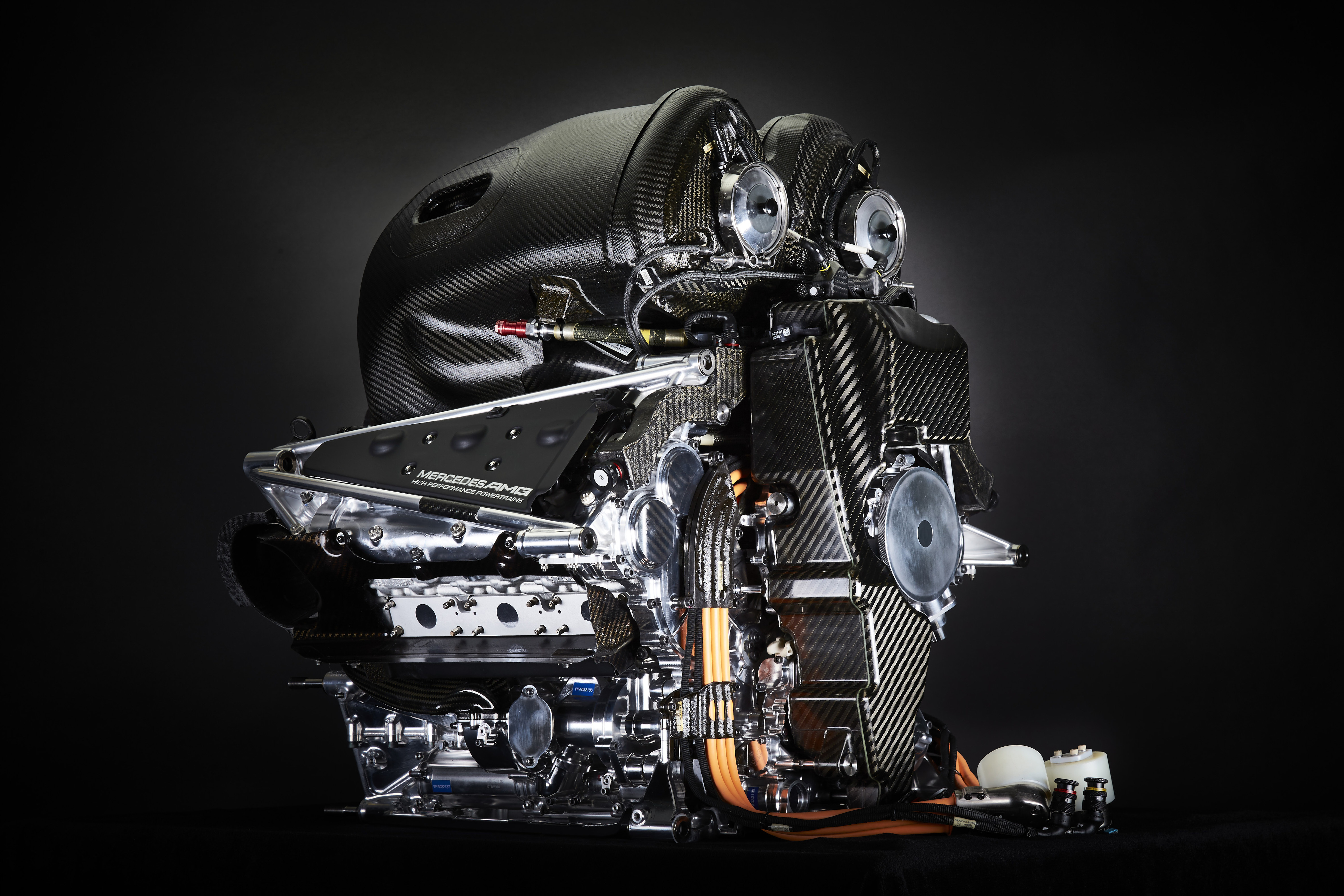

If you look at the mountings between the honda engine and the frame. If y is the length of the car and z is the height. The bottom ones (between engine and ladder ) are beefed up in the transversal direction supressing rotation and x movement. The top ones with the triangle are stronger in y direction.

The combination will supress most movements except some kind of frame bending or shearing in the yz plane.

That could be by design. Or it could have no meaning at all if the design is overdimensioned. Or it could mean that that movement is not present enough to spend material on.

These kind of things are hard to tell from pictures, but they could already be present in current designs.