Hello all.

Here is a Portable Flyer wherein the design is focused on the safety, without compromising in the rest areas.

ENGINE

ENGINE

Two OPRE Tilting engines, each having 350cc capacity (86mm bore, 30+30=60mm stroke) preferably the PatBam version for HCCI combustion (no need for high voltage circuit).

The two engine casings are secured / bolted to each other:

to form the Portable Flyer casing.

I.e. there are two independent propulsion units, each comprising an engine and two counter-rotating propellers.

Portable Flyer total mass: less than 20Kg / 44lb.

PORTABLE FLYER SIZE

With 3-blade propellers having 39’’ (991mm) diameter,

and with 21’’ (533mm) distance from propeller axis to propeller axis,

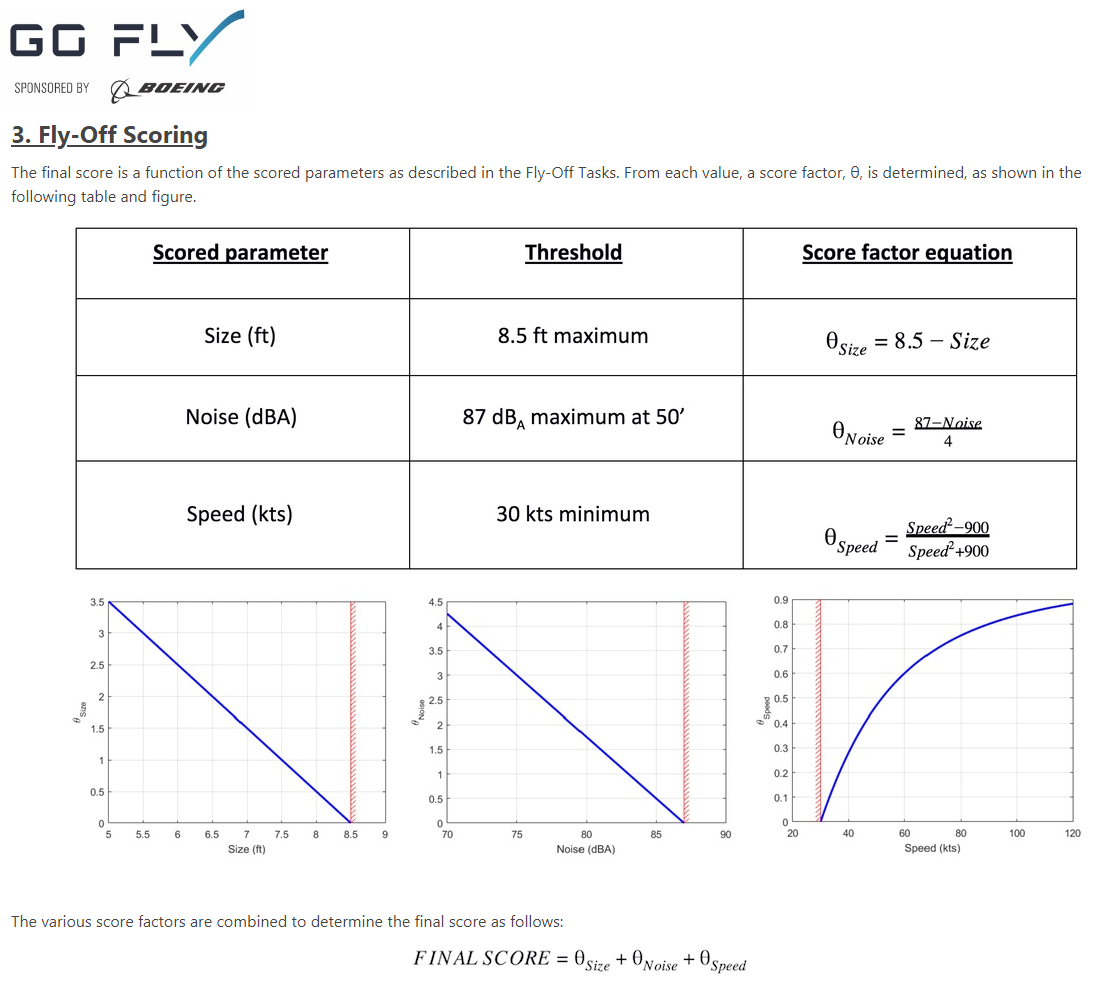

the maximum dimension of the Portable Flyer is 39’’+21’’ = 60’’ (3.5 points (35% of the maximum Final Score) in the “compact size” scoring of the GoFly competition:

https://www.herox.com/GoFly/guidelines sponsored by BOEING).

QUIET TAKE OFF

Limiting the propeller tip speed at only 150m/sec (44% of the sound velocity) for “quiet” take off, the resulting propeller rpm is 2,900rpm.

With 28’’ pitch and 3 blades per propeller, the static thrust at 2,900rpm is ~35Kp / 350N (at least according

http://www.godolloairport.hu/calc/strc_eng/index.htm ; if anybody has another static thrust calculator, he can check it out), while the power absorbed by each propeller is ~15bhp.

At the “quiet” take off, the total upwards thrust is 4*35=140Kp (with a total mass <110Kg, this means ~0.3g upwards acceleration) and the required power from each engine is ~30bhp.

The small tip speed keeps the noise low, and the “noiseless” scoring high (GoFly / BOEING competition: the quietness counts for some 40% of the Final Score).

With 2.4:1 “crankshaft to propeller” reduction ratio, the 2,900rpm of the propellers at the above “quiet” take-off, translates into 7,000rpm for the engines.

In order a 350cc 2-stroke engine to provide 30bhp at 7,000rpm, it needs to make 30mN of torque at 7,000rpm (~90mN/lt specific torque, which is easily attainable even with 4-stroke engines).

After the take off, the engine rpm (and the propeller rpm) increase to enable a high cruise speed (above 100mph (160Km/h)).

TOP SPEED

At top speed (> 100kts / 185Km/h) the propellers rev at 4,350rpm (propeller tip speed 2/3 of the sound velocity), and the engines are running at 10,500rpm (at 10.5m/sec mean piston speed, which is still low and improves the long term reliability).

In the scoring of the GoFly / BOEING competition (see figure “speed” at

https://www.herox.com/GoFly/guidelines) this means less than 0.05 points below the maximum possible (this counts for less than 0.5% of the maximum possible Final Score).

SAFETY

In case of malfunction of the one engine, or in case one propeller falls apart, or in case a transmission tooth belt is broken, or . . ., the “healthy” propulsion unit is capable for a safe landing.

With the one only engine running at 9,000rpm (mean piston speed: 9m/sec) and driving its two 3-blade 39’’ diameter / 28’’ pitch propellers at 3750rpm (2.4:1 reduction):

the total thrust force is ~115Kp,

the tip speed is 195m/sec (57% of the sound velocity),

the power required from the running engine is ~65bhp (which means: ~50mN of torque from 350cc capacity, i.e. ~150mN/lt specific torque, which is attainable by a good 2-stroke: the Rotax 850 has more than 175mN/lt peak specific torque).

With “only” 195m/sec propeller tip speed, the Portable Flyer is quiet even during an emergency landing.

FAST TAKE OFF

With both engines running at 9,000rpm, the upwards acceleration at a “fast take off” is more than 1g (10m/sec); it is like “falling towards the sky”.

Alternatively: the Portable Flyer can carry two persons (the pilot and a passenger); in this case at a malfunction of the one propulsion unit, the emergency landing is not possible (unless the one person (the pilot or the passenger) falls, preferably with a parachute).

CRUISING / CONSUMPTION / MILEAGE

With the pilot wearing a wing suit,

at 100mph cruising (87kts / 160Km/h / 44.5m/sec) the required thrust is about 30Kp (300N, 66lb) and the calculated power is ~18bhp.

(the data are taken from

http://www.dropzone.com/news/General/Fi ... t_613.html )

At cruising the propellers rev at 3,750rpm (propeller tip speed 57% of the sound velocity), and the engines rev at 9,000rpm (mean piston speed: 9m/sec)

With, say, 75% propeller efficiency, the power required from the engines is ~24bhp.

With the engines running at 35% BTE (attainable with HCCI combustion and lean mixture), the fuel consumption (gasoline) at 100mph (160Km/h) cruising is easily calculated at ~5.5lt/h (3.5l/100Km), and the mileage at 67mpg (US gallons).

For a distance of 200miles (320Km), they are required some 11lt (~8Kg) of gasoline.

Each engine has to be capable of providing, at 9,000rpm, the 65bhp required for an emergency landing (as previously described). Compared to the 24bhp required for cruising at 100mph, the engine(s) at cruising will operate at substantially light load (quite lean air fuel mixture if HCCI).

The straight line a Portable Flyer follows going to a specific destination is a big advantage as compared to a car and to a motorcycle which cover a substantially longer distance following the road.

HIGH SPEED AND SAFETY

The ability for high speed flights is mandatory for the safety; at windy weather a big size / slow moving (“hovering”) flyer is like a “feather in the wind”.

If the Portable Flyer can fly way faster than the wind, the strong wind is not a problem.

USE

In the near future the Portable Flyers (or the Personal Flyers) appear as interesting alternatives for cars / motorcycles / boats etc (which means wide use).

For special uses, the Portable Flyers appear as a passé partout.

Think of:

A “first aid” doctor arriving into a couple of minutes and landing 5m from the injured persons.

A rescue team flying to a sinking vessel.

A fireman who, at a skyscraper fire, is taking off the road and is landing in seconds on the roof of the skyscraper to help (or to take away) trapped persons (if each engine alone is capable for an emergency landing, the Portable Flyer is capable to lift, besides the pilot, a passenger (or two: the Portable Flyer mass is counted only once)).

COST

Regarding the ownership cost, a Portable Flyer like the above is way simpler than a car or motorcycle (it needs not wheels, it needs not suspension, it needs not a steering, . . .): just two simple, lightweight, vibration-free engines forming the casing, and four propellers.

Regarding the running cost, according the previous calculations a Portable Flyer appears more economical (and more green) than a car or motorcycle.

ENGINE (again)

The two OPRE Tilting engines are the heart and the backbone of the Portable Flyer.

The “OPRE” stands for Opposed piston Pulling Rod Engine while the “Tilting” refers to a valve secured on the small end of the connecting rod; the tilting valve controls the intake and the transfer (no need for reed valves or rotary valves). More at

http://www.pattakon.com/pattakonTilting.htm

Each “crankcase” (actually the space underside the piston crown, inside the piston) runs not-pressurized.

The thrust loads are taken at the cold ends of the engine, away from port openings.

The synchronizing gearwheels between the two crankshafts run unloaded and serve as balance webs, too.

Each engine, alone, is perfectly vibration free, and is driving its own pair of counter-rotating propellers (zero gyroscopic rigidity).

The short piston stroke (30mm) allows high revs at low mean piston speed (reliability).

With HCCI (i.e. spontaneous) combustion into a compact bowl, the over-square design is fine; the combined stroke is 30+30=60mm; with 86mm bore, the design is by far less over-square than the famous Ducati Panigale 1299 (60.8mm stroke, 116mm bore).

The pulling rod architecture increases substantially (~40%) the piston dwell at the combustion dead center enabling more “constant volume combustion”.

The single-piece “pipe-like” casing improves the stiffness, the lightweight, the simplicity and the low cost.

THEORETICALLY SPEAKING

All the previous are just theories; yet, interesting theories.

The safety is the “big issue”.

Having two independent propulsion units (each alone capable for emergency landings),

having also a parachute (for just in case, say when it runs out of fuel),

having (optionally) three small wheels like:

for emergency airplane-like-landing on a road or on a flat field,

the safety appears better than the safety provided by the conventional airplanes and helicopters.

AMENDMENTS ARE REQUIRED

In the previous the GoFly competition (sponsored by BOEING) was mentioned only as a reference point.

Surprisingly (because the BOEING is involved) they focus on the quietness and on the maximum dimension (8.5ft maximum) of the device: 90% of the total scoring is for the noiseless take-off / landing and for the maximum dimension of the Personal Flyer.

SUMMARY

In the double-propulsion-unit OPRE Tilting Portable Flyer presented above, nothing appears near or beyond the current state of the art limits.

Lightweight carbon-fiber propellers of various designs and sizes are available in the market at low prices.

Toothed belts are common place for power transmission and revs reduction.

The structure of the Portable Flyer utilizes the engine casings as its backbone.

The perfect vibration free (including both, inertia vibrations and power pulses vibrations) is a requirement when a powerful engine is to be directly supported / secured on the body of the pilot/rider; otherwise a long (say of one or two hours) flight would be a torture.

The counter-rotating propellers eliminate the gyroscopic rigidity and allow the pilot/rider to vector the thrust immediately and effortlessly to the desired direction.

Every ounce of mass that can be omitted from a personal flyer, must be omitted. The more the mass of the flyer, the more fuel is required for a specific range and the more challenging the take-off / landing becomes.

The peroxide JetPacks consume some 30Kg of “fuel” in half a minute.

The jet powered personal flyers (Yves Rossi like, Zapata like etc) consume their fuel in ten minute, or so (BTE less than too small).

The electrical personal flyers are based on batteries; and the existing batteries have an energy density several dozens of times lower than the fossil fuels (gasoline, kerosene, Diesel etc). The energy density of the power source is more than important for a flying device.

The body and the eyes and the senses of the pilot/rider are available; why not to use them as the fuselage and the sensors and the control system?

Isn’t this what the birds are doing?

Relative to the birds, the low power to weight ratio of the human body is the only thing that restricts us from flying / hovering.

This lack of power is what the OPRE Tilting engines and the propellers are curing at a true “neutral” and efficient way.

Thanks

Manolis Pattakos