etusch wrote: ↑08 Jun 2018, 13:35I found this after searching that Apple

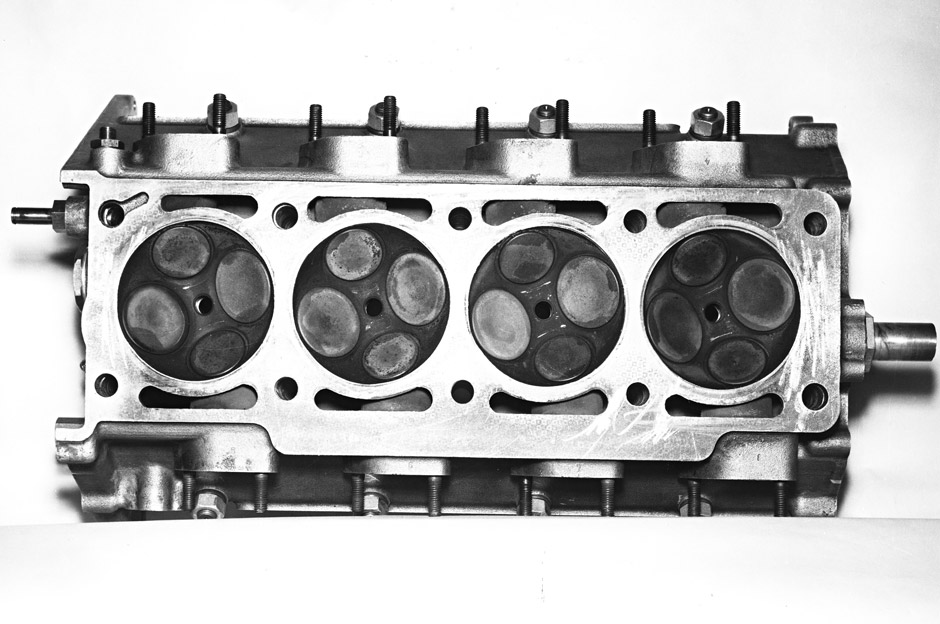

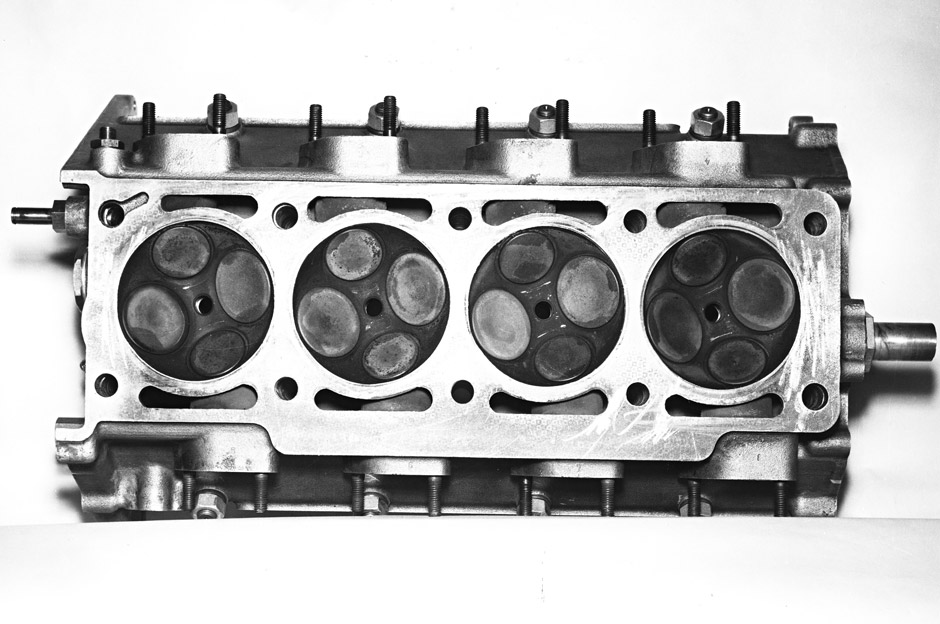

https://historicmotorsportcentral.com/2 ... -head/amp/

etusch wrote: ↑08 Jun 2018, 13:35I found this after searching that Apple

https://historicmotorsportcentral.com/2 ... -head/amp/

I don't really have a big opinion on it, just that Nissan and Toyota are sporting tumble in all of their big power direct injection engines.gruntguru wrote: ↑08 Jun 2018, 01:47I disagree (unless you are talking about scavenge during overlap). . . and who cares about the efficiency of that flow regime? If you want more scavenge flow just increase the overlap period.PlatinumZealot wrote: ↑07 Jun 2018, 03:39I think there is a scavenging disadvantage. Just visualizing the exhaust escaping to two opposing sides makes my head hurt.gruntguru wrote: ↑07 Jun 2018, 01:03The ability to create swirl with minimal flow penalty is one advantage. More importantly, the design has more flow potential. The paired valves (eg 2 x inlets), being further separated than a pent-roof design, have less tendency to "shroud" each other. The ideal implementation would have downdraft ports (near the spark plug) which tends to favour flow down the cylinder walls rather than towards the other inlet valve disrupting its flow,

.I think swirl is more effective than tumble (tumble extinguishes rapidly near BDC compared to swirl). Its just that pent roof heads and chambers don't lend themselves to swirl - the tangential component of flow from a single intake valve is cancelled by the second intake valve. The Apfelbeck chamber is almost conical (even close to TDC) and will support swirl at any piston position.Two valves on one side gives more tumble and there are a few videos out there from big car makers that illustrate how modern "trip" and tumble designs have proven to be optimal for direct injection engines. Though interesting i cant see Honda going to such a clumsy and heavy design just for swirl. It would be easier to have two different sizes of intake valves or staggered opening or something.

A nanosecond is a billionth of a second (.000000001). An expansion stroke lasts .01 seconds at 12k RPM. Five degrees before and after TDC would pass in .0018 s.godlameroso wrote: ↑09 Jun 2018, 18:50Don't Toyota or whoever create tumble with port geometry? The "ski ramp" is made easier with wider valve angle but not impossible with a narrower angle.

I'm guessing the ideal for the pre-chamber requires some mixture of swirl and tumble, and the timing of either during the piston stroke is critical. And you can tune a lot of this with your valve opening and closing events.

One of the things that makes engines so interesting is that the time scales for each combustion event are tiny, and so many things have to be properly timed to get the most out of it. From the fuel breaking then forming bonds to the pistons and valve train motion, and flame propagation, all of it needs to be precisely timed to the nanosecond.

And what about the bond breaking of the hydrocarbons at the spark gap? The species propagation in the pre-chamber? The EGR after she goes bang? How many sparks in that .0018s, injector pulses?roon wrote: ↑10 Jun 2018, 05:47A nanosecond is a billionth of a second (.000000001). An expansion stroke lasts .01 seconds at 12k RPM. Five degrees before and after TDC would pass in .0018 s.godlameroso wrote: ↑09 Jun 2018, 18:50Don't Toyota or whoever create tumble with port geometry? The "ski ramp" is made easier with wider valve angle but not impossible with a narrower angle.

I'm guessing the ideal for the pre-chamber requires some mixture of swirl and tumble, and the timing of either during the piston stroke is critical. And you can tune a lot of this with your valve opening and closing events.

One of the things that makes engines so interesting is that the time scales for each combustion event are tiny, and so many things have to be properly timed to get the most out of it. From the fuel breaking then forming bonds to the pistons and valve train motion, and flame propagation, all of it needs to be precisely timed to the nanosecond.

What about spin direction of their constituent quarks? What about the topological defects which may have formed during a symmetry breaking phase transition in the early universe? If we don't time these events down to the last femtosecond, we'll never break 50% thermal efficiency.godlameroso wrote: ↑10 Jun 2018, 06:10And what about the bond breaking of the hydrocarbons at the spark gap? The species propagation in the pre-chamber? The EGR after she goes bang?roon wrote: ↑10 Jun 2018, 05:47A nanosecond is a billionth of a second (.000000001). An expansion stroke lasts .01 seconds at 12k RPM. Five degrees before and after TDC would pass in .0018 s.godlameroso wrote: ↑09 Jun 2018, 18:50Don't Toyota or whoever create tumble with port geometry? The "ski ramp" is made easier with wider valve angle but not impossible with a narrower angle.

I'm guessing the ideal for the pre-chamber requires some mixture of swirl and tumble, and the timing of either during the piston stroke is critical. And you can tune a lot of this with your valve opening and closing events.

One of the things that makes engines so interesting is that the time scales for each combustion event are tiny, and so many things have to be properly timed to get the most out of it. From the fuel breaking then forming bonds to the pistons and valve train motion, and flame propagation, all of it needs to be precisely timed to the nanosecond.

#aerogollumturbof1 wrote: YOU SHALL NOT......STALLLLL!!!

It is nice for academic purposes but the Law of Diminishing Returns prohibits it for actual applications.godlameroso wrote: ↑10 Jun 2018, 06:24That's the spirit. No seriously the fuel guys are really looking at those time scales. They have the computers and the nerds for it.

A lot but not in the nanoseconds realm