subcritical71 wrote: ↑30 Oct 2018, 16:14

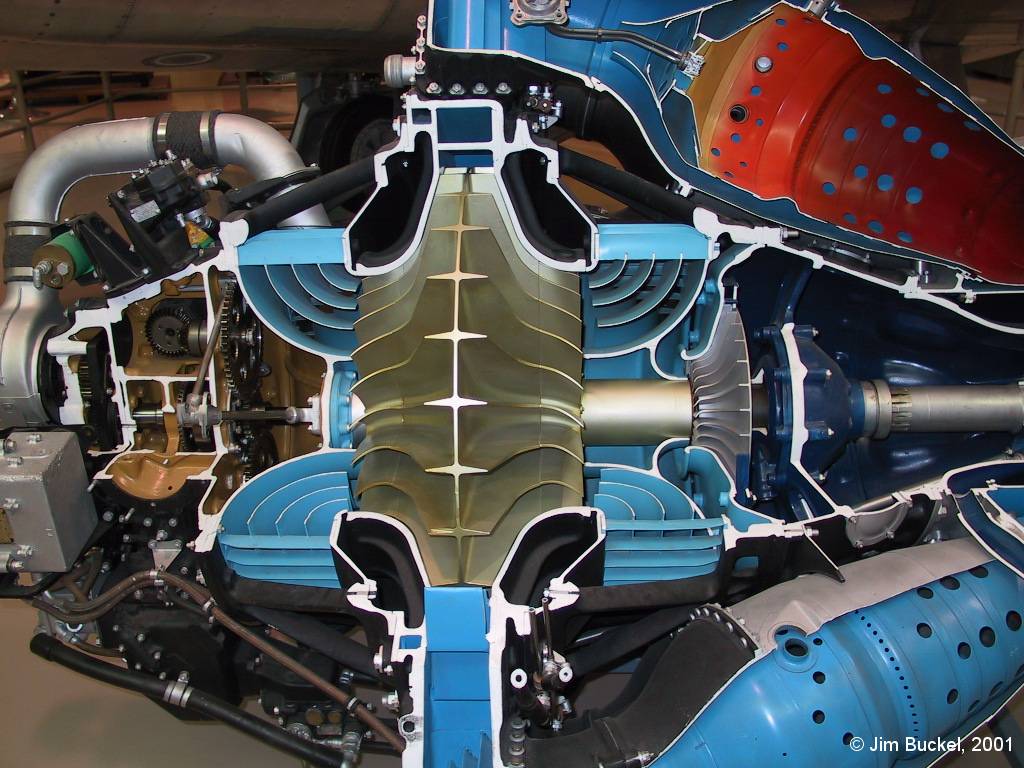

Also, the discussion is not one of is it a two stage compressor because of the number of outlets/inlets as they have nothing to do with the number of compressor stages. The discussion is on how many stages exist on the compressor shown (RR Nene 10). With its seemingly split design I would think it would be classified as a two stage compressor, however, that normally means one stage feeding another. In the case of the photo, the flow is split... so is that a two stage compressor to the FIA?

Staging and splitting are not related. You can make twin scroll turbines (each scroll will have its own entry) to improve on "response times" because it'll reduce the interference between cylinder pairs that overlap in scavenge. Splitting the compressor, this is my guess, is probably just for convenience (with the plumbing) but I'll very much like to be corrected on that. (Or anything else I clearly don't understand for that matter.)

Staging can be done by either having multiple turbos in a serial configuration, or by having more than one turbine wheel on the same axle, possibly interspersed with stators. I don't know if one turbine wheel and one (or two) sets of stators would count as multi-staging however.

Multi-staging is done to improve on the overall pressure ratio across the entire compressor system or, I presume, the overall "recovery" of the whole turbine system.