The thread (a fantastic thread if I might say so myself), consists largely of me transcribing posts from that forum member by PM, which I received one engine at a time, with me adding a consistent format and pictures available on the net.

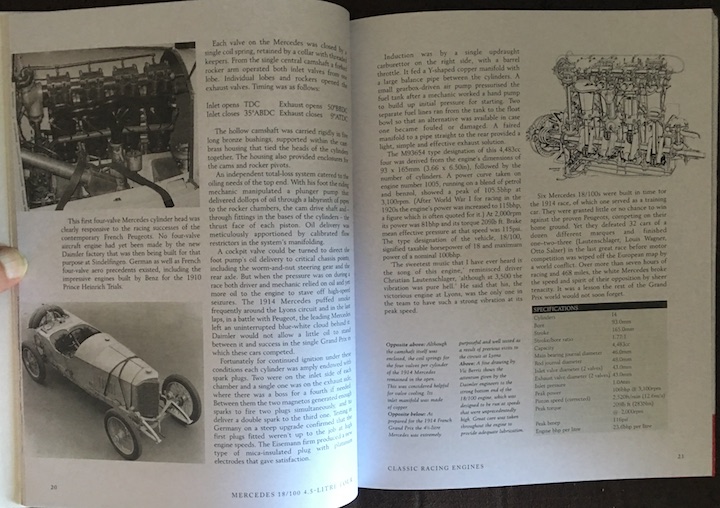

As it turns out, there is a book called “Classic Racing Engines” by Karl Ludvigsen, published in 2001, which consists of information on 50 racing engines from different categories, from the super-famous to some a bit more obscure, from 1913 to 1994. The list of 50 engines in the book appears to be an exact match to the 50 engines described here. The book also includes a much more lengthy description of elements of the engines and some side stories about them, and gives a list of specs for each engine that appears to match the data in this thread virtually verbatim. If you liked the thread, you might like the book, 120% for sure.

I will not draw any conclusion on the time-line here, although I want to publicly apologize for my role on this.

For anyone interested, I would like to drop a couple of links to that book by Karl Lugvigsen. Example pages of what the book provides can be found here: https://speedreaders.info/18722-classic-racing-engines/ and I provide an example as a picture:

.

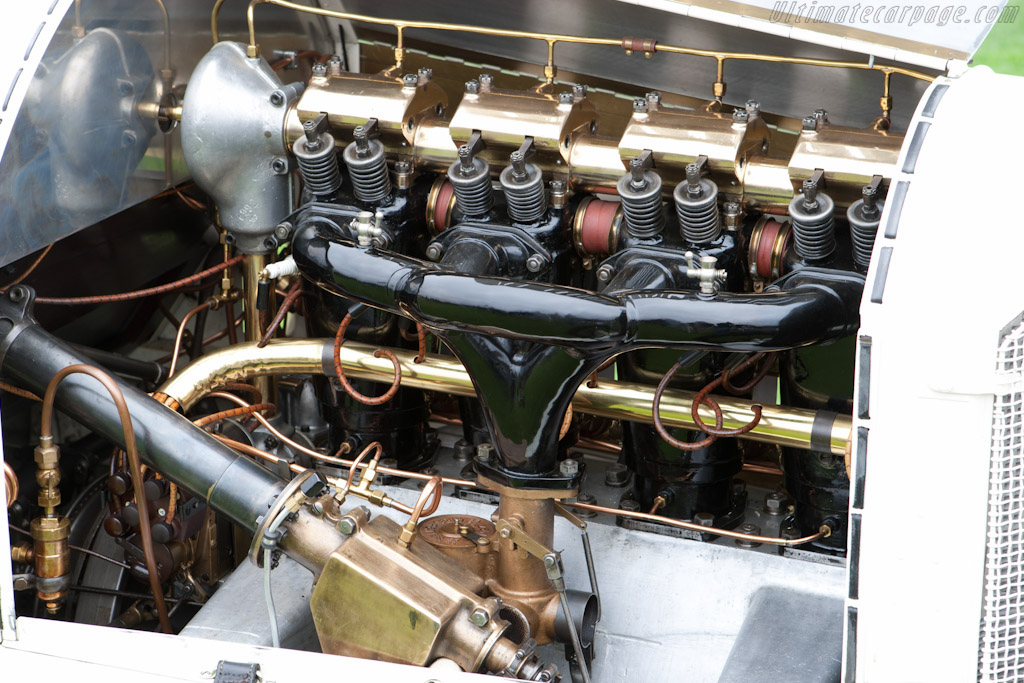

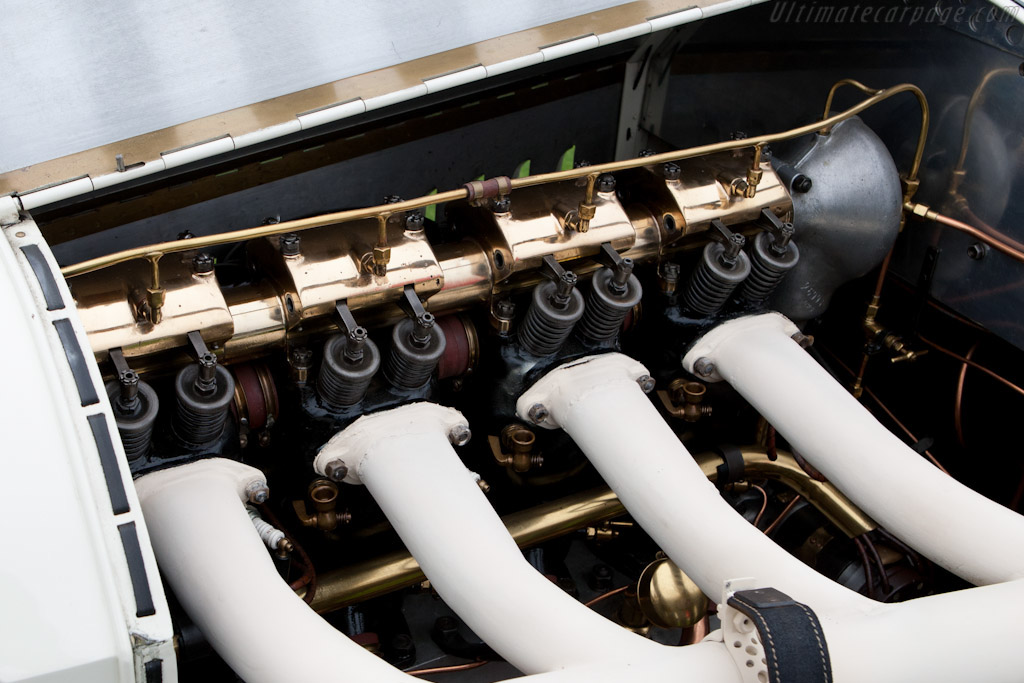

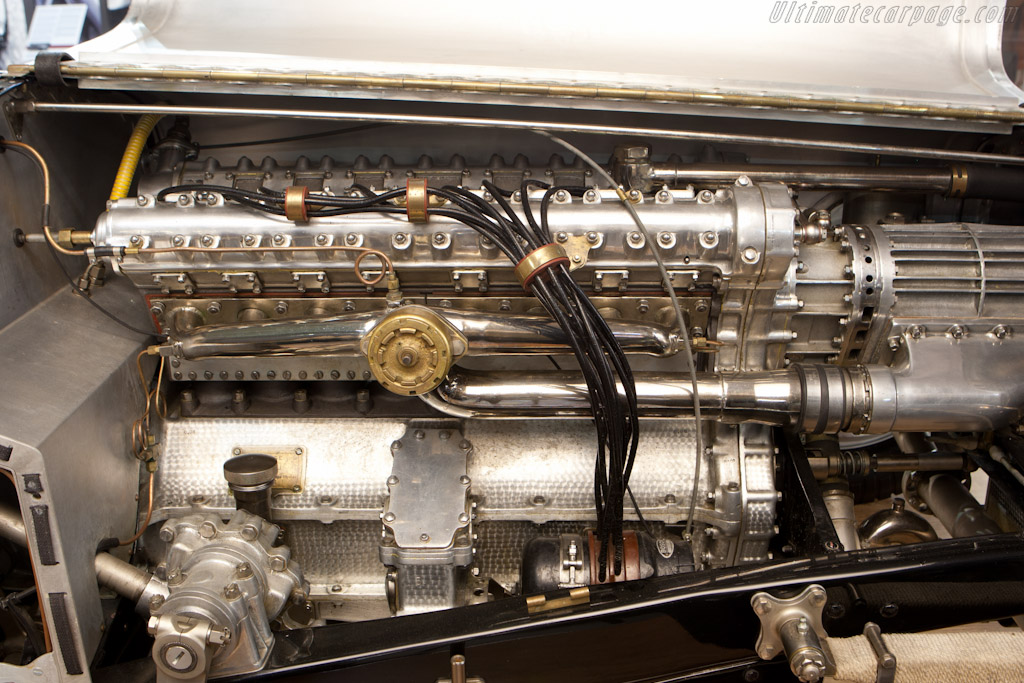

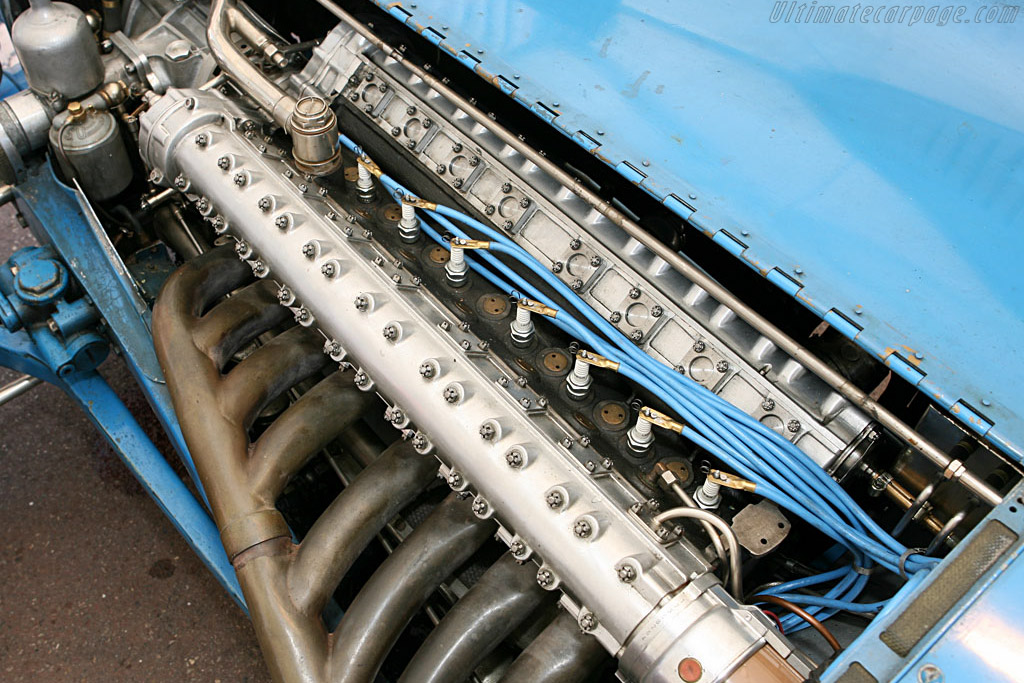

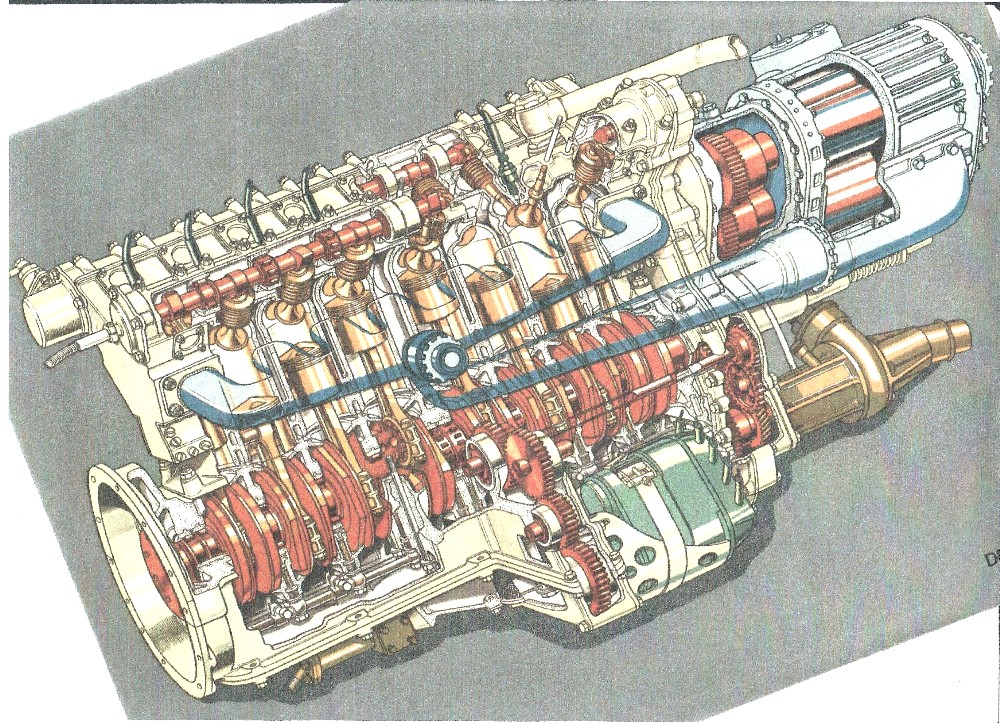

. Nice pics of cars and engines, as well as technical drawings are part of what the book delivers. The cutaway Küchen engine was apparently the first of its kind and launched a career of cutaway engine drawings: viewtopic.php?p=1037722#p1037722

Where to find the book “Classic Racing Engines” including a 2017 edition:

http://www.bentleypublishers.com/automo ... tents.html

https://www.amazon.co.uk/Classic-Racing ... +Ludvigsen

The book’s author kindly requested if we could attach some reader comments, and we are happy to oblige, given the special circumstances:

Amazon comments on Classic Racing Engines

Reviewed in the United Kingdom on 25 July 2002

As an introduction to the development and successes (and failures!) of some of the most celebrated racing engines, this is a fine overview. But trying to pack the history of something like the Cosworth DFV or the Offenhauser into four pages (one of them a full-page picture) means that the history gets a little too telegraphic. Readable, but you know that Ludvigsen knows and could write a lot more about these engines!

Reviewed in the United Kingdom on 13 November 2008

This book is aimed at car enthusiasts who already know how engines work but want to gain an overview of the features that separate racing engines from everyday motors. If you don't know anything at all about engines, the book is far too technical to act as a primer. However, for petrol heads and enthusiasts of single seat open wheeler racing cars it is a wonderful book. Only long-term students of racing engines could fail to be informed by its content and delighted by its clarity and breadth.

Reviewed in the United States on 14 January 2004

I own hundreds of automotive books, but "Class Racing Engines" is the one that I read over and over. It combines deep technical information, fantastic photos, rare blueprints, and most important of all, Ludvigsen's unique ability to place things within a historical context.

What I like most about this book is how it puts you right in the shoes of the engine designer. What should the valve angle be? Hemispherical combustion chamber? Materials? Number of bearings? You get the picture... this book gets you deep into motor design and then wallows around in it. It's almost a sinful delight to read.

Reviewed in the United States on 18 January 2011

Not as detailed in the 'specification' category as I first expected but who wants to read pages full of stats anyways? I've an automotive background so wanted to know more about every subject but given the few books dedicated to automotive engines this one is a keeper.

Weighted towards older engines but has a good look at more modern ones. It is interesting to look at the bhp/ton over the years as this illustrates the technology/ material / thinking differences.

I'm sure you could criticize it if you wanted but it has given me years of reading pleasure and will do for more to come I'm sure.

The book’s author Karl Ludvigsen also asked for a shout to his new blog:

You could also help by suggesting that readers who are interested in my work sign up for my new Substack column here: https://karlludvigsen.substack.com It’s free for now and I need more readers to sign up!

Below is the original OP of this thread.

*********************************************************************************

Hi all,

saviour stivala is offering a list of specifications, with descriptions, collected over the years, on a series of significant racing engines spanning most of the 20th century. Focus is on Grand Prix engines, starting even before WWI; but many will fall within F1's realm once the 1950s are reached. I'll be doing the postings a few at a time, but the schedule will be rather irregular.

This list is not meant to be exhaustive in any way, but I think it offers an interesting window into competition, power train and technology development.

Please feel free to pollute the thread extensively with more details, anecdota, pics, competitors and just anything under the sun.