http://www.grandprixhistory.org/mas4clt.htm

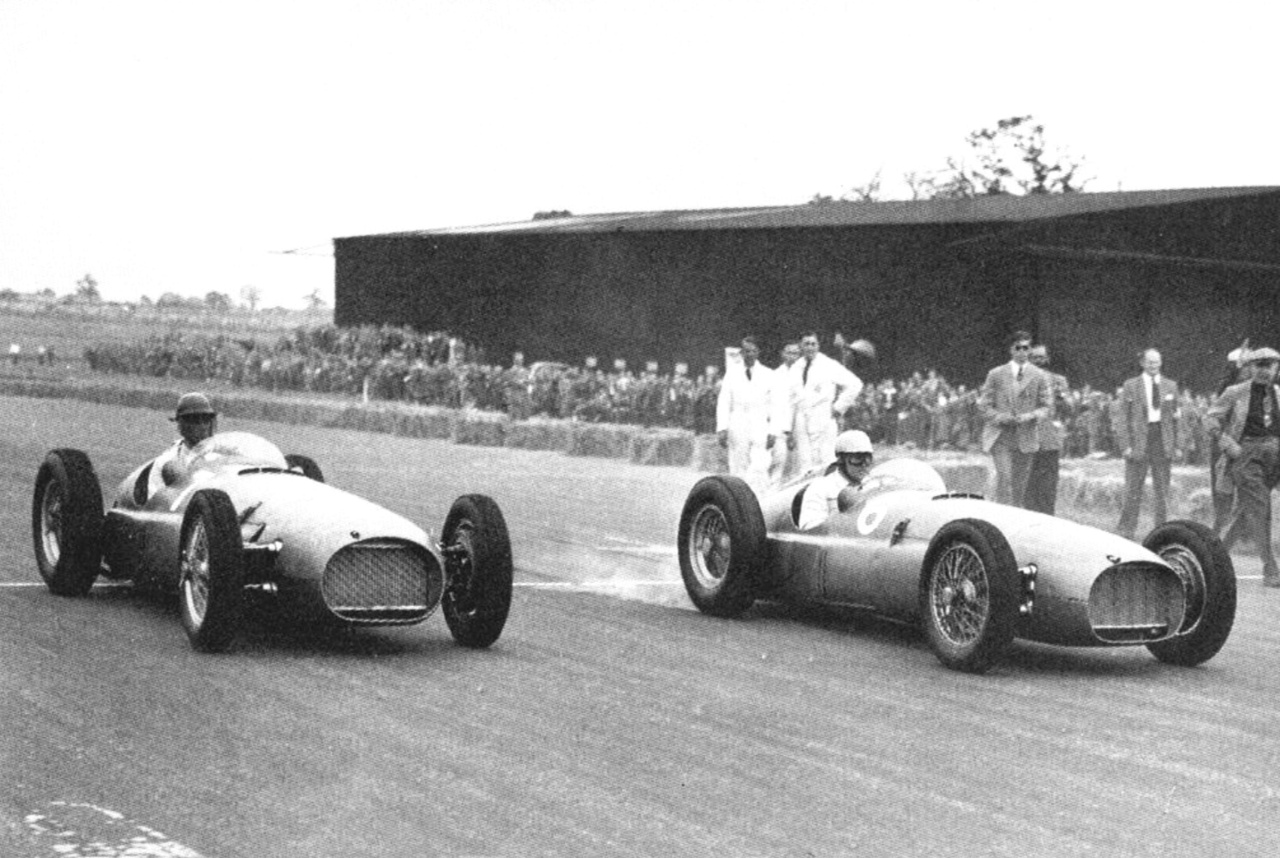

This was an entrant in the first Formula1 race, so this had to be the car's picture:

Edit: Fangio’s onboard removed. Wrong car, wrong year.

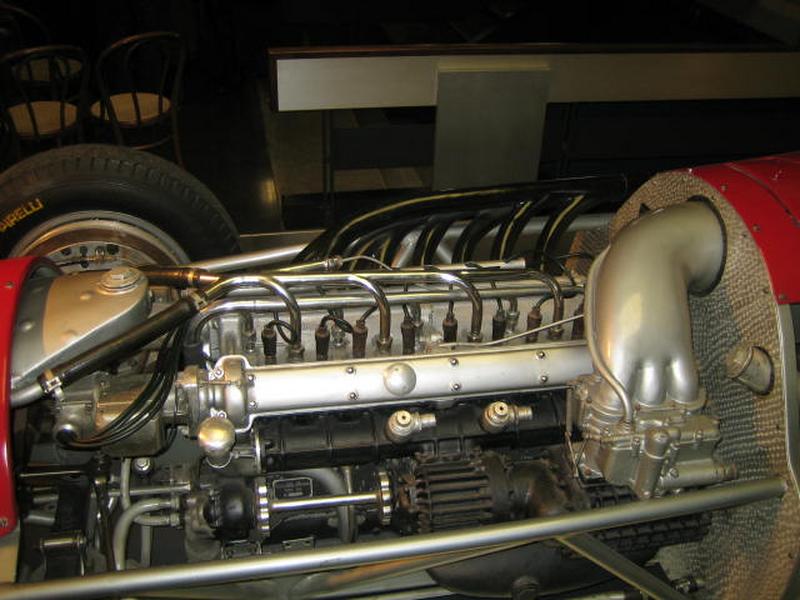

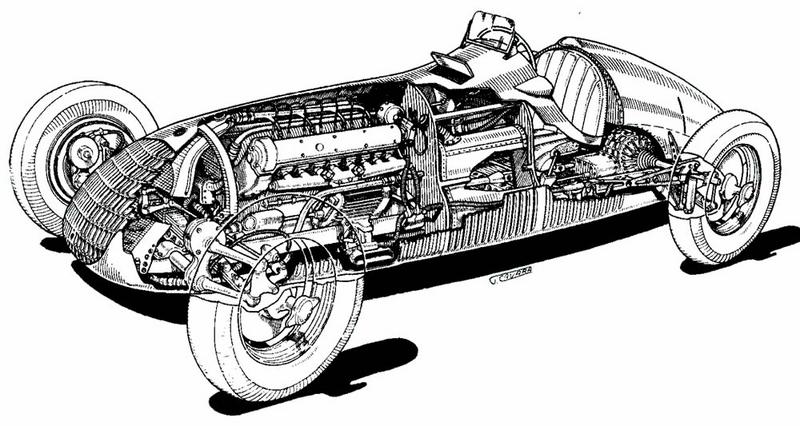

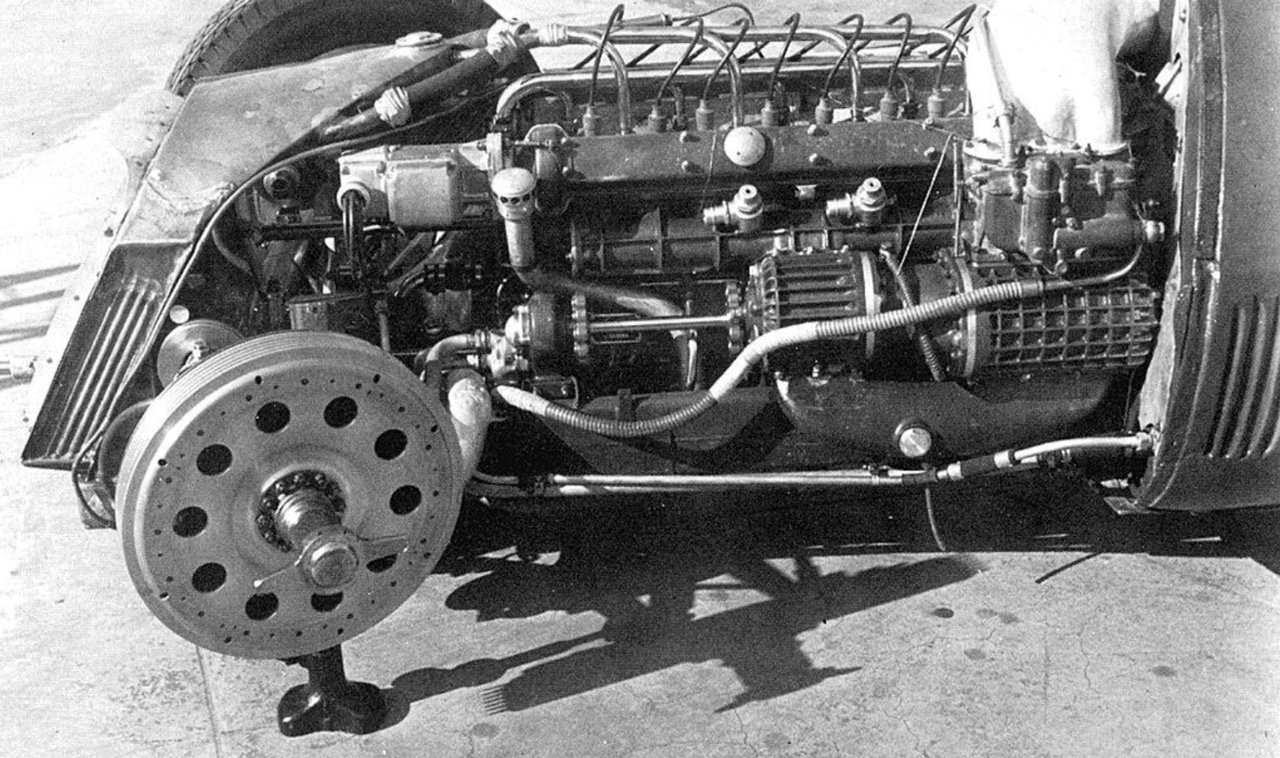

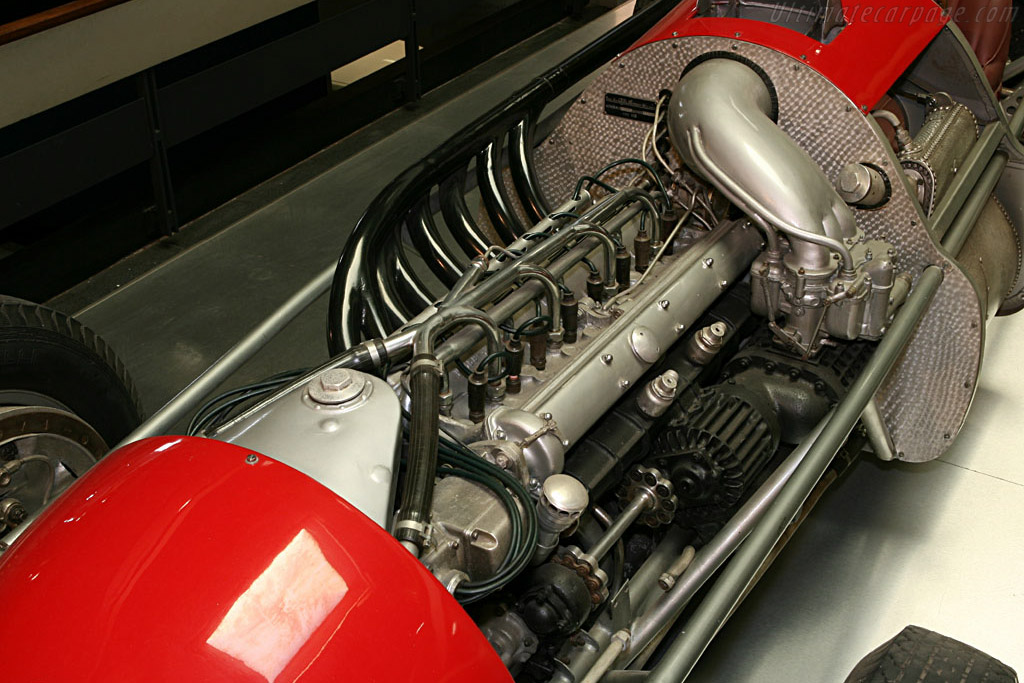

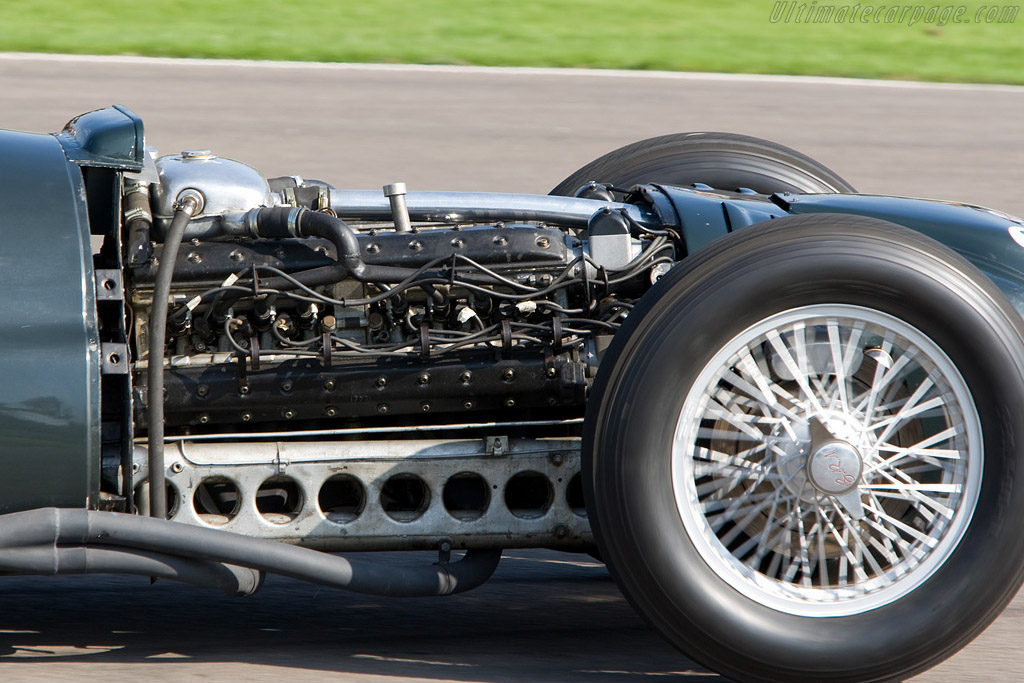

Of that 135 HP, approximately 64 would be recovered due to 30 psi intake pressure driving the pistons down during the intake stroke.hollus wrote: ↑13 Jan 2019, 14:461951 Alfa Romeo 159 1.5-litre eight

. . . .

The engines were burning more than 150 litres per 100km by 1951. More boost, up to 30psi allowed the engine to develop 420BHP@9300RPM, well over double the original output. The power required to drive the superchargers was 135BHP.

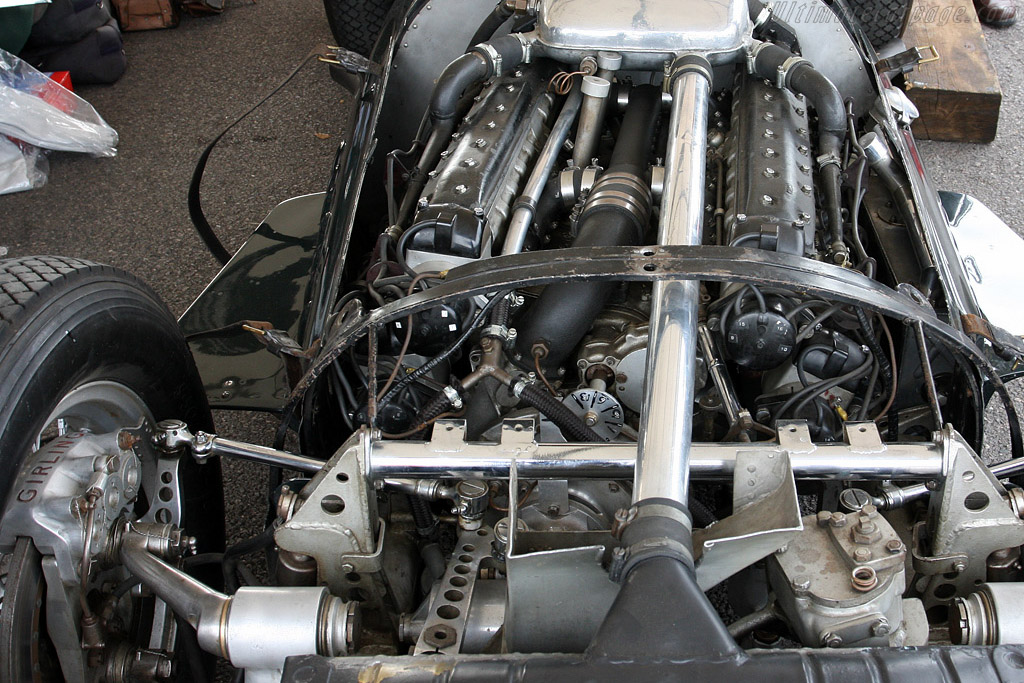

well in Griffith Borgesen's writings it was (the fishplates)

Possibly yes, the story behind the type 15, the technicalities, the complexities the sheer amount of people involved in its masking, the in-build design fault, all of which unfortunately lead to one of the biggest engine flops of all time. The one coming up next in the series is the totally opposed extreme, very little is known about it including the name, just one individual man is involved, he made just 3 of them in his own workshop all by himself, for someone who could not collect them, this was a case of extreme engineering ingenuity, so extreme that it is said that this genius even had to make the rollers for the crankshaft bearing himself, this individual produced a 2-litre V8 engine with an output that the big guns of the time could not match. Till it comes up.