Hey Jon,e36jon wrote: ↑25 Sep 2018, 01:50I love a challenge, so off to Google I went in search of Mercedes splayed bolt F1 rods. Yeah, not happening. I did find this though:

Ran across this today as well. It's a MMC rod with a polymer coating aimed at the drag race crowd. It's 'almost to market' for four years now (Hence no link)... Anyway, shows the thinking Mudflap was referring to:

https://imageshack.com/a/img921/7838/oAjdNR.jpg

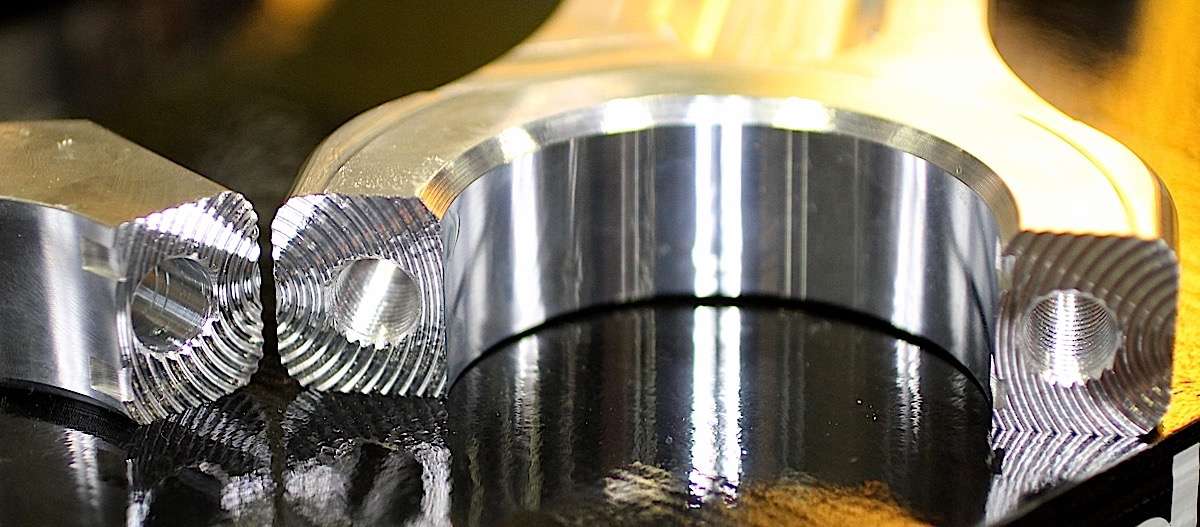

Doing the web search also pointed out the 'splayed 4-bolt main caps' used in these same engines, but for different reasons...

Yes, this is exactly the rod bolt configuration they have used!

I did a bit of searching and found a patent :http://www.freepatentsonline.com/20040107794.pdf

To be fair though the more I think about it the fewer structural reasons I see for having the bolts like this:

1)Having the bolt head located closer to the parting plane increases the alternating loads on the bolt.

2)Thread not breaking through creates a thin section close to the last thread which is also the thread experiencing the largest alternating stresses! Virtually all of the modern racing rods shown on the first page have break out threads with a huge radius on the last thread (best seen in the Honda rod cross section). Plus you can't easily measure bolt stretch (you can do it ultrasonically but not even F1 teams to that !).

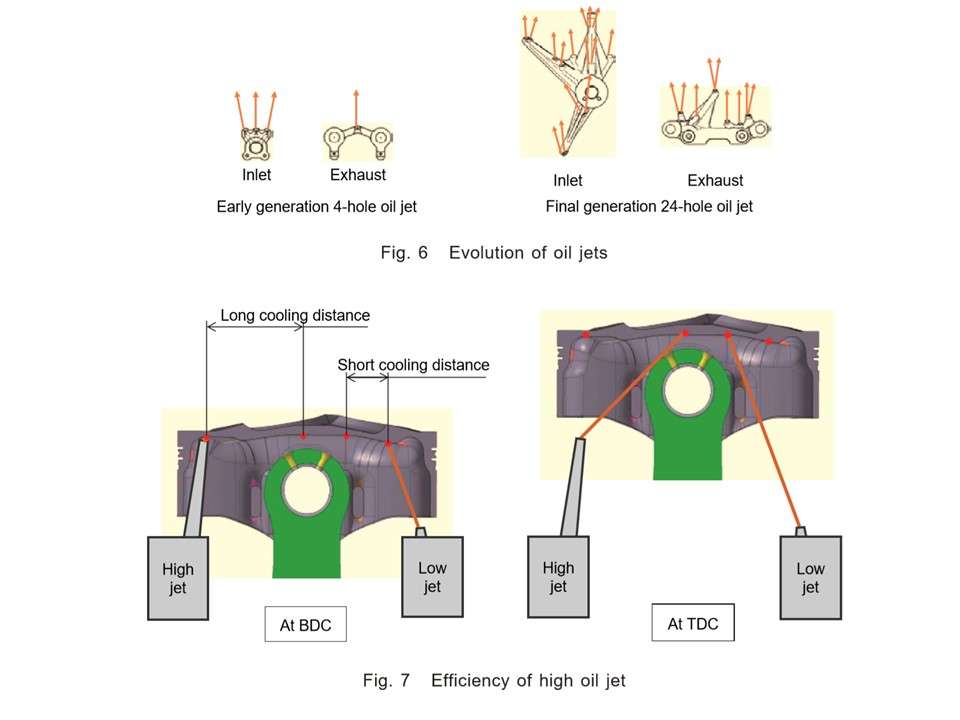

On the pro side the splayed bolts move the bolt cap up which means that the cranktrain can drop lower - this is absolutely critical in F1 (see the rod swept volume explanation in the Honda paper).

I don't really buy the "increased lateral stability" reason given in the patent either - provided that the joint doesn't open or slip the bolt orientation shouldn't really influence bore stiffness. I think it will only change the deformed bore profile. I do need to look into it to actually convince myself though.

As for MMCs used in rods I've only ever heard of SiC in Ti matrix so my guess is that's what they're using.