saviour stivala wrote: ↑11 Jul 2019, 06:45

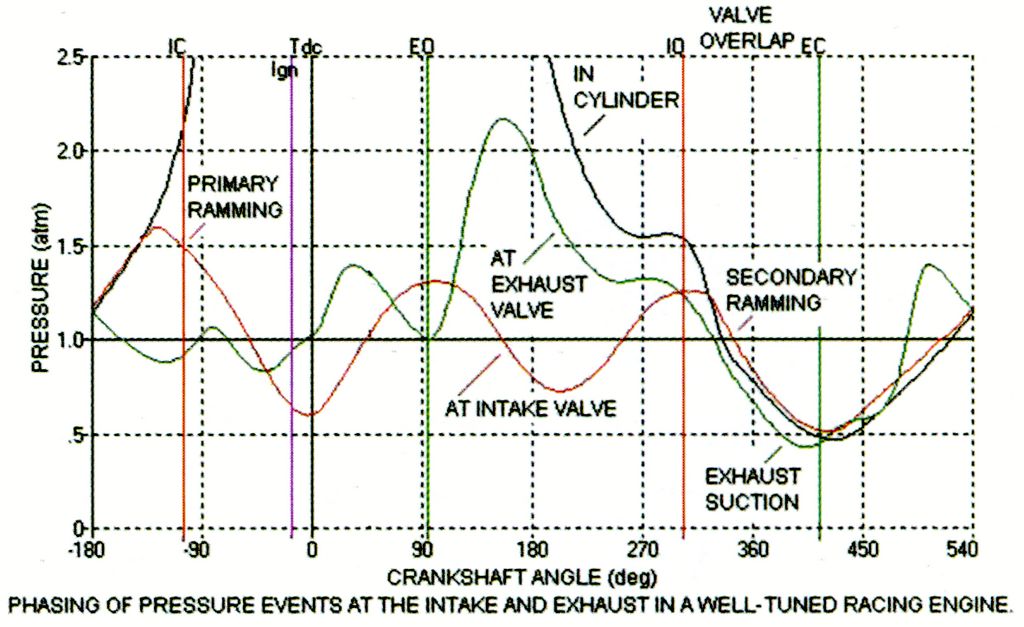

Wave tuning is a critical part of a naturally-aspirated engine’s efficiency, since it is the only way to create ‘charge’ motion o0ther than – and sometimes in spite of – piston motion. Wave-tuning is what made the huge jump from engines that only had effective filling in the 40 – to – 70 – percent volumetric efficiency range to the common 110 – to – 130/140 – percent numbers....

well ... and sincerely ....

what charges all NA engine other than/in spite of piston motion is 'Bernoulli' - kinetic energy changing into pressure energy

wave 'tuned-length' effects can be added to supplement this (for racing) - or be deliberately kept trivial (for your parents' car))

because wave tuning works essentially near to a fixed rpm (unless it's variable geometry) - and is also noise-generating

anyway all WT'd engines are simultaneously using Bernoulli

Bernoulli tells us when a moving column of gas is stopped the pressure rises according to the square of the gas speed

this means that eg the inlet valve can usefully be opened before tdc and closed after bdc and so help the VE

Be can give a VE close to 100% - but only where gas speeds are high ie peak at c.800 mph the 'speed of sound'

this means rather large ports and valves - to keep peak gas speed subsonic even at 100% rpm

but eg at 50% rpm Be is only giving 25% benefit (and cams designed for Be at 100% rpm are wrong for 50% rpm)

road engines of course had small ports/valves to get max Be at rpm well below 100%

so the charging/rev fell at high rpm as the ports 'choked' via losses in attempting supersonic peak gas speeds

the result was a practical though unexciting torque/power curve

even race engines were compromised in this - different designers having different ideas

eg the Cosworth DFV chose/had unfashionably high gas speeds from seemingly (to some) 'small' ports and valves

the trend-setting pre WW1 GP Peugeot had huge ports and seemingly no appreciation of Bernoulli (or wave tuning of course)

judging by the designed valve timings

it chose very low gas speeds for laminar flow 'to minimise flow losses' (wrote L H Pomeroy Jnr)

ironically the size of the porting to atmosphere is important in WT and Be (it controls pressure differences of course)

eg the 1967 McLaren F1-destroked Ford Detroit Indy V8 had lacked power at high and low rpm

until the intake (porting to atmosphere) diameter was reduced (increasing pressure differences)

early post WW1 GP winners had extended valve timings and WT (on the induction side anyway)

invented by motorcycle racing then car racing on ovals in the UK and USA

inlet port and valve sizes for Be helped power curve (eg 1923 Fiat-clone GP Sunbeam had 3 gears vs preWW1 Peugeot 5 gears)

European inter-war NA motorcycles developed extreme WT incl megaphone exhaust but had good Be by not over-porting

this drove later NA F1 design though most compromised on exhaust and/or inlet side for power curve reasons

till liberated by intelligent injection/fbw throttles, vg induction tracts, and 7 speed paddle shift gearboxes

when I claimed a NA VE of 125% was possible proof was demanded (not from s s) - so doesn't 130%-140% seem high ?

of course the car's forward speed can increase VE and power

and increase the power from exhaust thrust power (this at max speed about 3% of current F1 PU ?)

and of course the exhaust process at high % powers in all piston ICEs is choked

(even if the valves were infinitely large and opened infinitely quickly it would be)

choked by the high loss of pressure as some/much of the flow necessarily is supersonic

in current F1 the potential of the exhaust gas is thereby degraded - the process is in part thermodynamically irreversible

presumably somewhat limiting the recovery potential by further expanders

though usefully choking and its losses are reduced according to the density (exhaust pressure) upstream of the turbine