Hello all.

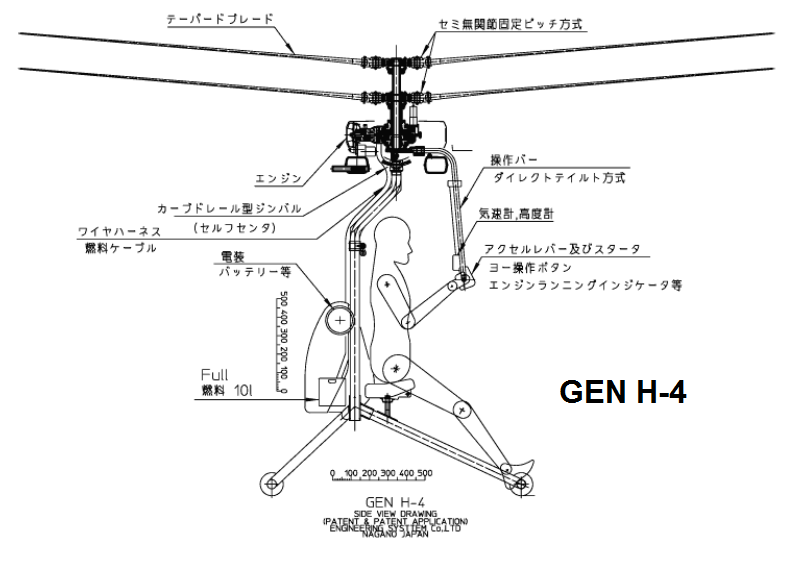

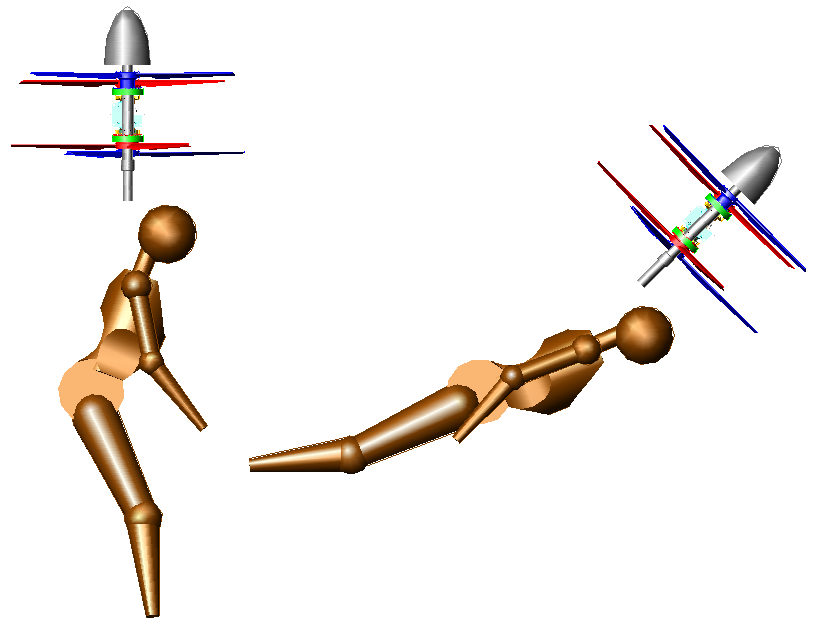

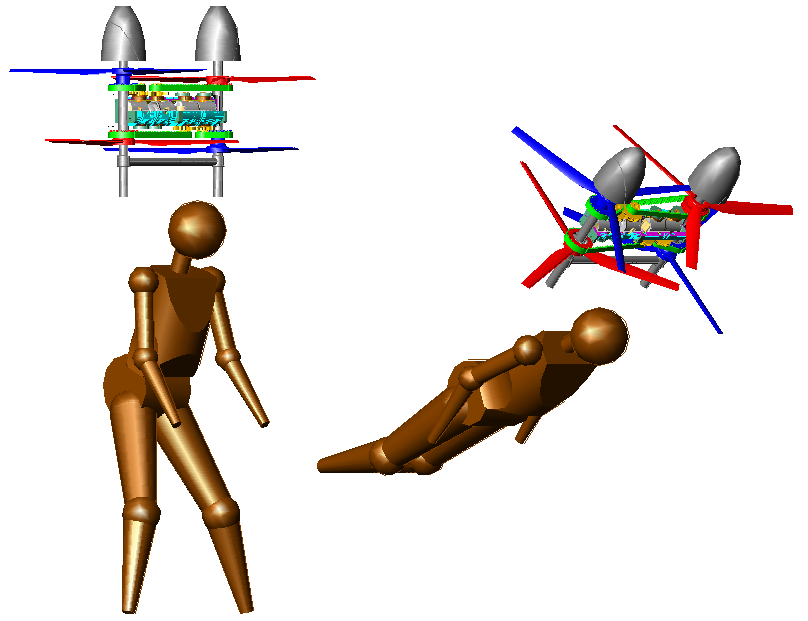

The demonstration of the OPRE Diesel (that with the aluminum propellers) in the youtube video points to airplane application:

- Replace the “lightweight tripod that stands free on the floor” (where the OPRE Diesel of the video is bolted on) by the nose of a lightweight airplane, and you have an interesting combination.

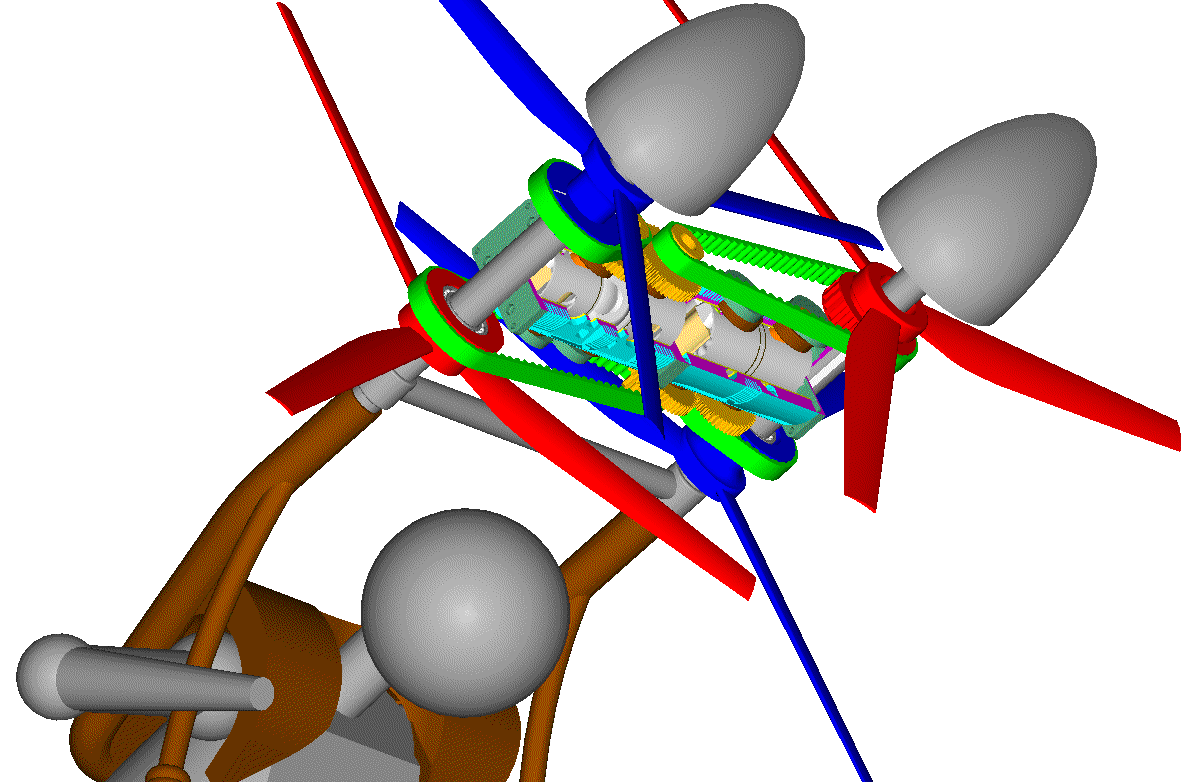

Bore: 80mm,

Combined stroke: 50+50 = 100mm,

Total height: 505mm,

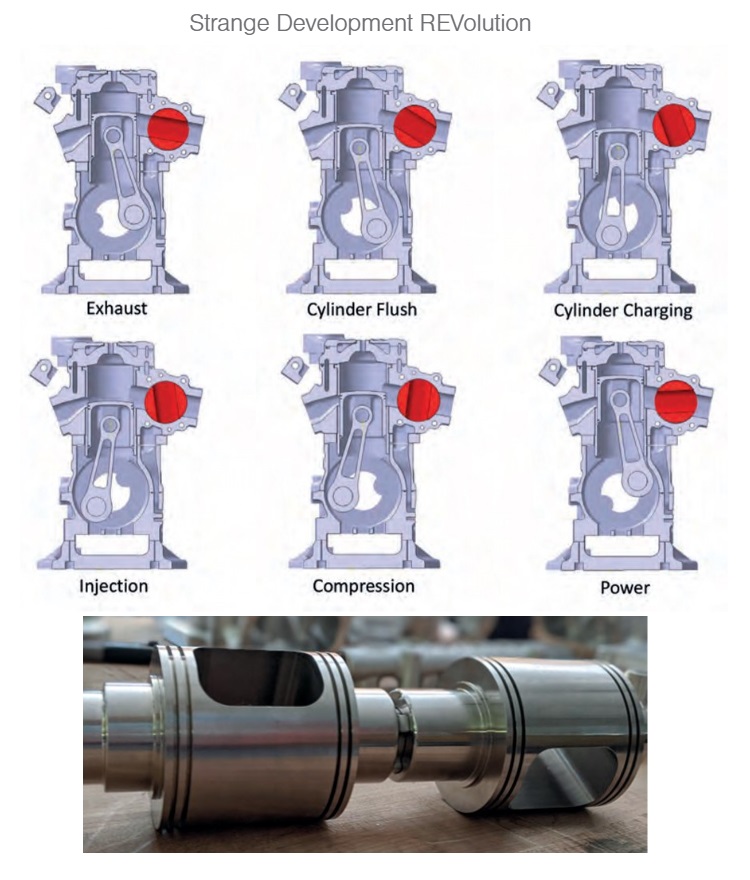

Direct Injection compression ignition with “pulling rod” architecture,

17:1 compression ratio.

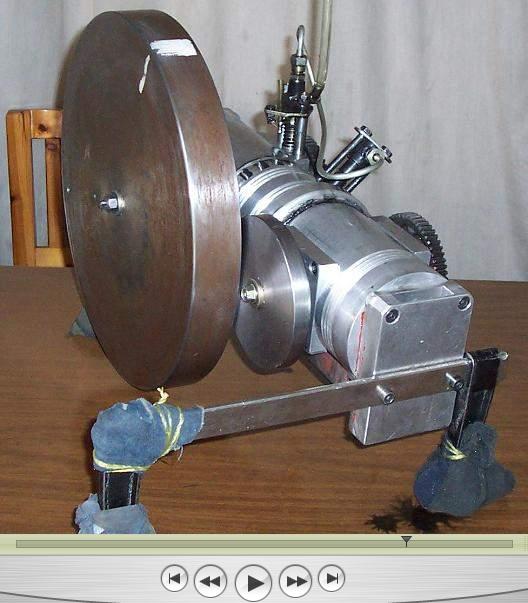

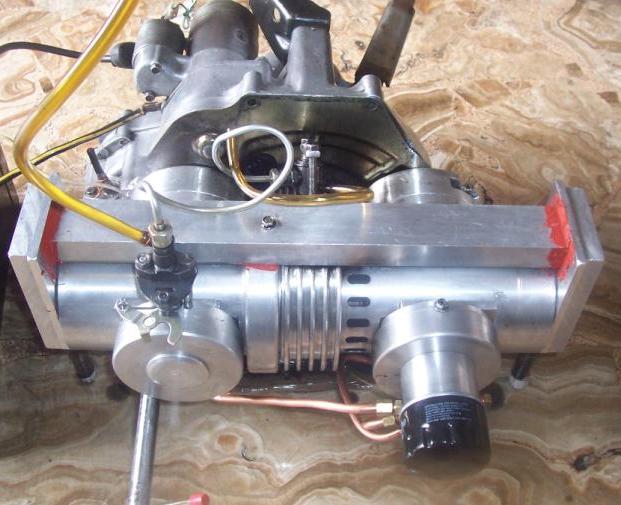

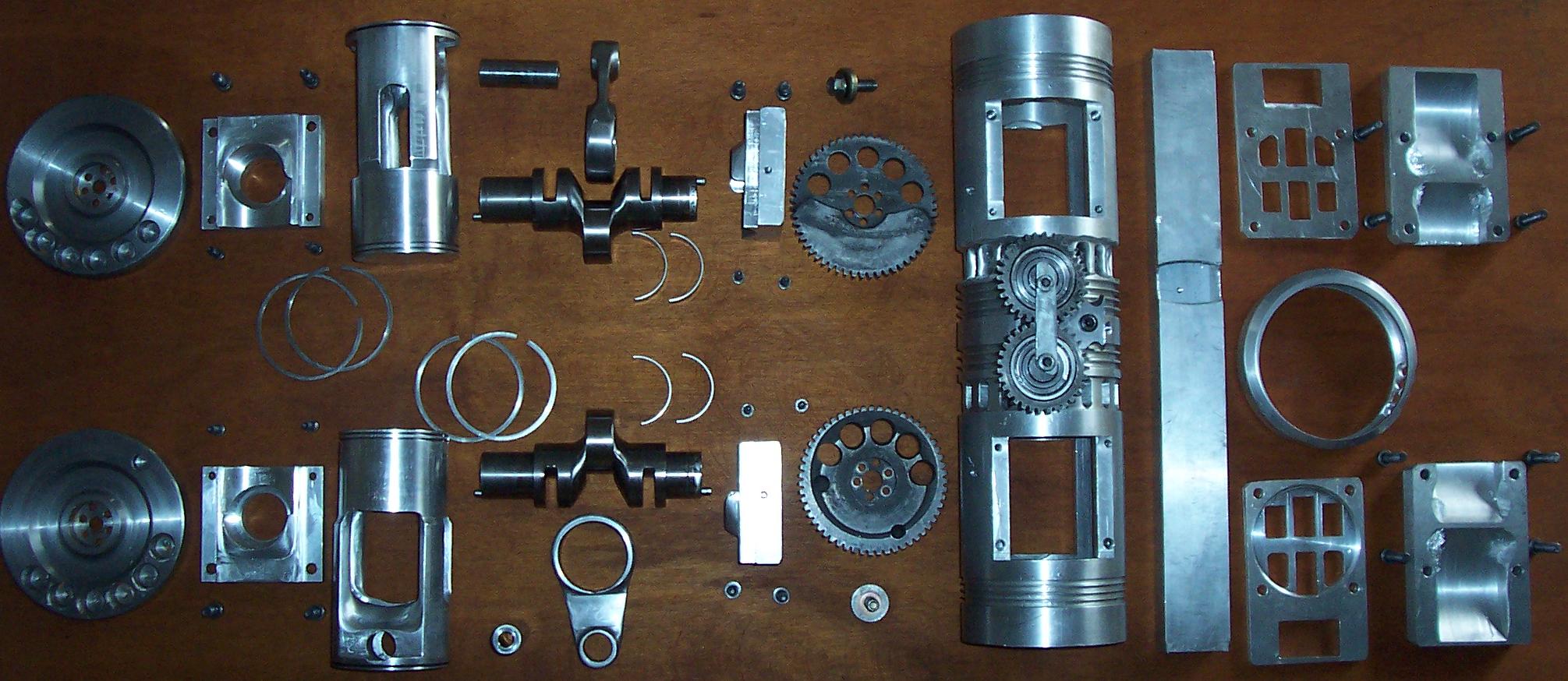

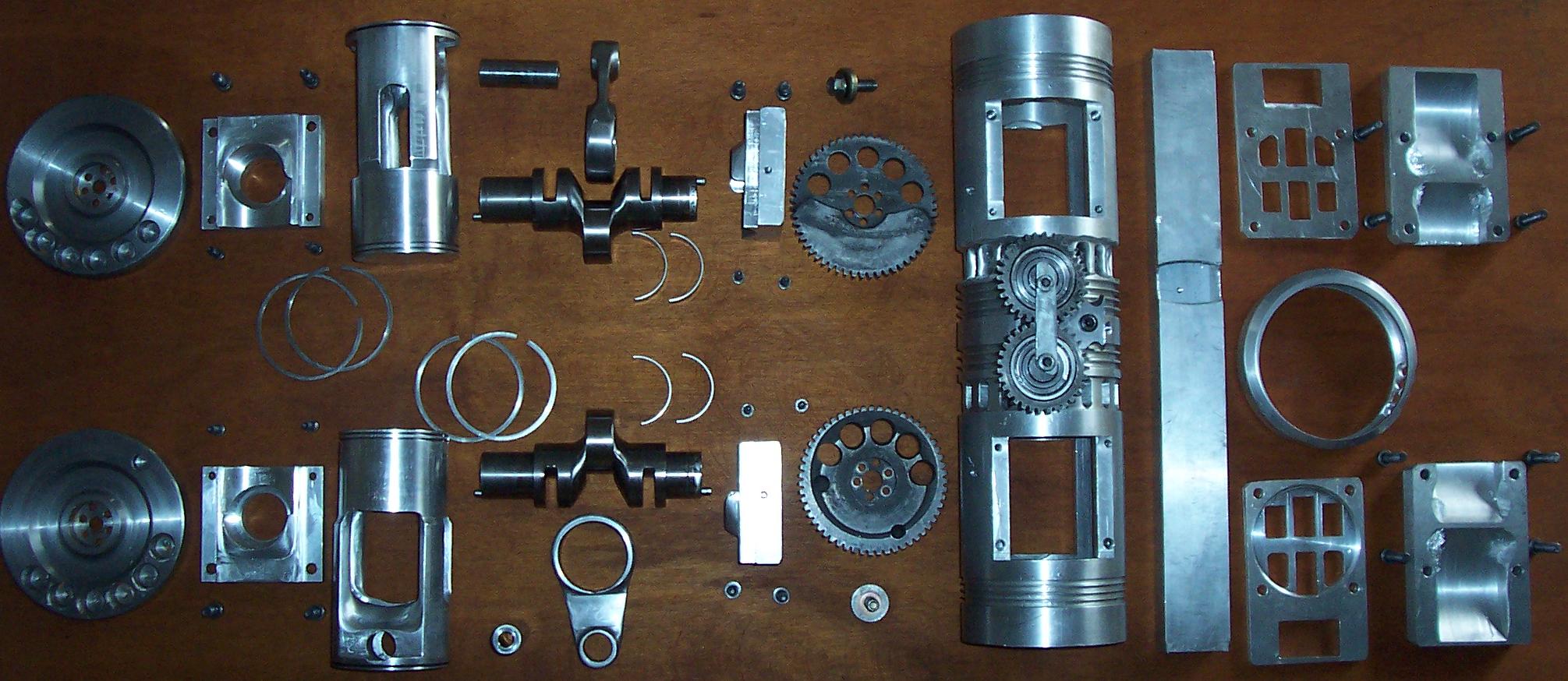

Here are the parts of the prototype engine:

A lot of metal can be removed without affecting functionality.

0.5lt (30 cu.in) capacity,

built-in piston-type scavenge pump,

direct drive of the counter-rotating propellers (each one directly bolted on its own crankshaft),

high-pressure pure-mechanical fuel-injection (no electrical system, at all),

overall weight, including the propellers: 20Kg (after the removal of the unecessary material from the prorotype),

perfectly balanced (no vibrations on its basis),

zero reaction torque on the basis.

Besides its weight, the only loading of the frame of the airplane by the above propulsion unit is a forwards thrust force. Nothing else. Elastic mounts are not necessary.

The last characteristic (

no reaction torque) is important for the safety of lightweight (and ultralight) airplanes wherein an abrupt opening or closing of the “throttle” (or a missfiring) may cause destabilization (even upside-down turn).

Important for the safety is also the Diesel fuel which is less flammable than the gasoline.

The absence of high voltage electrical system is also important for the safety / reliability (think of the twin ignition systems and of the two spark plugs per cylinder used in spark ignition air engines). Without electrical system, no short-circuit can happen (even running under water).

Cranking safety:

With the engine bolted on the nose of an airplane, the manual cranking is as safe as the manual cranking of any other airplane engine.

Weight saving and cost saving come from:

the lightweight propulsion unit,

the “unloaded” frame of the airplane (no vibrations, no reaction torque, lightweight engine),

the better thermal efficiency of the compression ignition engines which calls for less fuel for a specific distance,

the even better thermal efficiency of the specific compression ignition engine (increased dwell at the combustion dead center: pulling rod engine architecture) which calls for even less fuel weight,

the smaller fuel tank etc.

Quality / Feeling:

With the airplane fuselage rid of inertia vibrations of all kinds and orders, rid aso of power-pulse vibrations of all kind and orders, this single-cylinder propulsion unit seems better in feeling / quality than any Wankel rotary and than any multicylinder piston engine.

Thanks

Manolis Pattakos