Well, you can call it factor of ignorance, but perhaps that's a pretty "antique" concept.

I do not design mechanical pieces, but I do design once in a while metallic pieces for buildings, bridges and some structures.

I don't know if mechanical engineers use the

Von Mises stress concept, but I would say yes. The text explains the (kind of) new approach to analysis: "All other items of interest will mainly depend on the gradient of the displacements and therefore will be less accurate than the displacements".

In that case, you do NOT increase forces. You use an increase in permissible strain. This means you do your analysis based on the context of finite elements. This is very important if you're designing complex frames and (over all) shells, as I imagine is the case for many elements in Formula One. After all, beams are "passé".

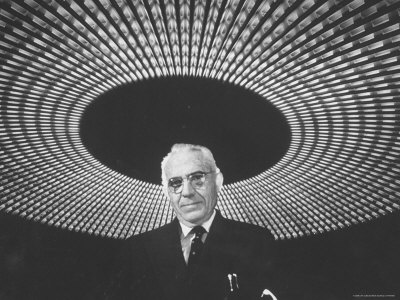

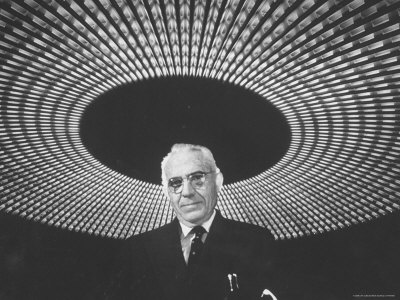

The concepts for finite analysis, afaik, were started by civil engineers, so allow me to give a picture of a master here...

Pier Luigi Nervi under the Stadio Flaminio, 1960, way before monocoques... and using concrete, a more difficult material

The general idea is that you use safety factors as

strains allowed because materials

accommodate. Even when you go over the elastic limit, there is a (not residual, but effective) plastic resistance. This is called

plastic design.

(I apologize if some people here, people like Pup, Greg or Callum roll their collective eyes, but perhaps not everybody is familiar with this).

This means that the building bends a little and it will be bent for life, actually. However, who cares? It can take it.

You actually "dare" to extract the last drops of resistance. Hence you use a safety factor measured in strains: you go into the plastic zone and you assume the material is going to be permanently "damaged", that is, it'll go over the maximum deformation that allow total recuperation of the form of the material. How much? Well, I've seen people going into half an inch. It depends on the material and the part.

After some decades of study of materials structural engineers have realized that there is not such thing as a mathematically exact strain-stress relationship

when you go into the atomic realm. All curves are approximations to the real behavior of materials.

So, I would not call it factor of ignorance, but factor of intelligence. Brembo uses around 1.1 but in plastic design, afaik.

Allow me to digress a little from the thread question, please, if you're so kind.

Long digression you do not have to read (actually, believe it or not, you do not have to read anything in this post!)

I will never forget when our teacher of soil mechanics explained to us the concepts of elasticity, plasticity and thixotropy. I may have mentioned here before (sorry, guys).

While he carry on with the lesson on stress-strain curves, he was playing all the time with a ball made of Silly Putty.

Field trip of awesomeness!

He explained elasticity and plasticity (elastic means it will recover from stress, while plastic will have a permanent deformation).

Then he bounced the Silly Putty ball against the floor. Let me explain that Silly Putty bounces

a lot. He asked us: ¿what's this material? We answered in one voice: "elastic!".

Then he stretched the ball. It behaved like chewing gum, of course. He asked again: "¿what do you think now? As you can see, this material exhibits permanent deformation...". Some said: "It's plastic!". Other said (smartypants): "It's elasto-plastic!".

Then he explained thixotropy. He told us that thixotropy means (I'm trying to abbreviate here) that a thixotropic material had a resistance that depended on the speed of the load.

For example, ketchup: when you apply a fast load (that is, you hit the bottom of the bottle) ketchup flows, but if you apply a constant load (that is, you turn the bottle upside down) it won't flow.

Thixotropic material (bentonite) showing "roll waves" depending on gellification under shear

For example, when you apply a slow load to asphalt, it will flow, but under a fast load it won't. That's the reason why there are so many potholes in toll plazas or parking lots (or the reason why you make them of concrete, which has negligible sensitivity to speed of load):

asphalt will flow when trucks go slowly.

Golden Gate Bridge Toll Plaza: notice the concrete surface in the stopping area

Anyway, when he finished he called our attention to the Silly Putty ball. He had left it on top of a table.

Under constant forces (that is, gravity), the silly putty flows (the exact opposite of ketchup behaviour), so there was a puddle of Silly Putty on top of the table. It had "melted" under its own weight.

The lesson? Materials are not that simple. They are not simply elastic, plastic or thixotropic... and soil less than anything. Soil is made of dirt, for the love of Pete. Who knows what it contains?

So, I think we are barely "scratching the surface" of material science these days. Hence, safety factors are not used (at least not in my profession) in more modern designs as simple factors that you apply to loads, but as permissible strains that actually take you under the "old" safety factor of 1, perhaps into designs that would be justifiable if you used (in the "old methods") safety factors of 0.9 or 0.8.

Anyway, as you have no idea what will happen in real life, you use them ("old" safety factors) to build structures that will be able to withstand forces you did not imagine it will take (like a hurricane in New York and a huge drop in temperature á lá "The Day After", or, as Greg clearly explains, planes that have to dodge a missile when a wind shear comes into play, or "standard" cars that have to take a kerb)

However, that's a different approximation: the one of durability and safety. In racing, you don't use that point of view

that much (that is, you are not worried about building for the centuries: the car will barely last for one season, and that's if you're lucky and FIA do not decide to change everything).

Duration is a virtue: Puente de Alcántara, a structure that has taken many things in the last 20 centuries... including relatively modern trucks. It's not safety factor, it's "durability factor" what plays here

I love materials.