In this thread I will be unlocking a few secrets hidden within this part - the F1 Spark Plug, mainly its construction, operation, and some other features. It is from one of the last Cosworth TJ V10 engines, similar was also used in the later Cosworth CA V8 which had a 20,000rpm+ rev limit. All in all, F1 Spark Plugs are all pretty similar although there are some small details that change between engines. As all head designs are different - F1 Spark Plugs can differ in dimensions and also how they seat onto the head - ranging from from crush washers, to taper seat or conical seat.

The key difference between an F1 Spark Plug and a standard automotive spark plug is the diameter and method of spark gap construction. In a normal spark plug the spark jumps from the central electrode to the outer case tang, or tangs. Modern plugs normally have four tangs for longevity. When one tang erodes out of tolerance the spark will jump around to the next nearest tang and so on. F1 Spark Plugs are different however in that there is no tang, but instead the outer case forms a concentric lip around the central electrode. This design is known as ''Surface Gap'' and can also sometimes be found in high powered bike engines as well as high performance road engines. Having no tang frees up space in the combustion chamber.

The main reason why F1 Spark Plugs are such small diameter is due to the valve sizes used in F1 Engines and also the space needed for coolant to flow as near as possible to the chamber roof and around the gallery directly above all four valve seats and spark plug counter-bores.

This coolant way area shown below in more detail,

Had the spark plug been of the conventional size the small ways between the spark plug counter-bore and port walls shown above would be lost - leaving a hot spot on the chamber face below it.

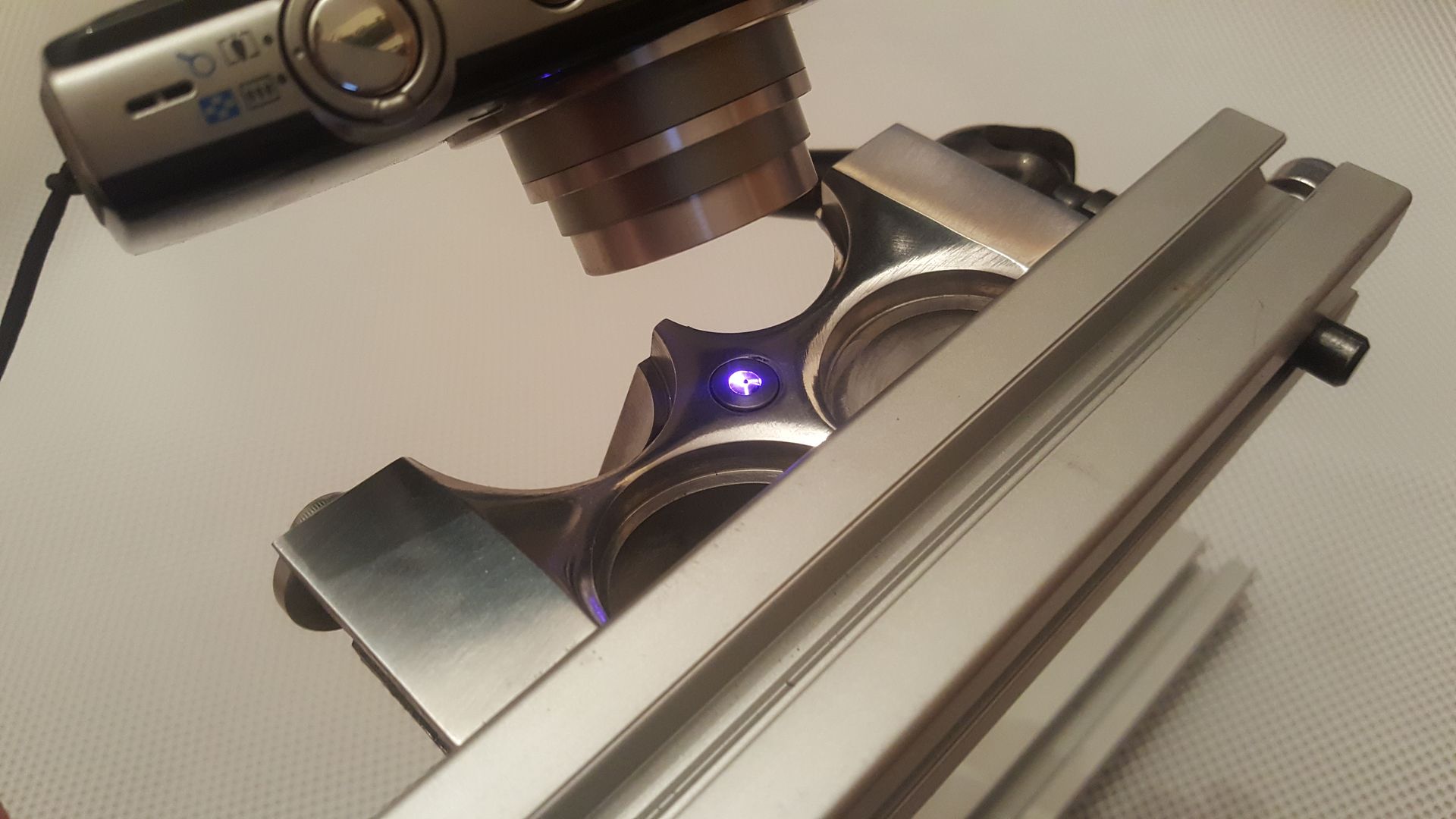

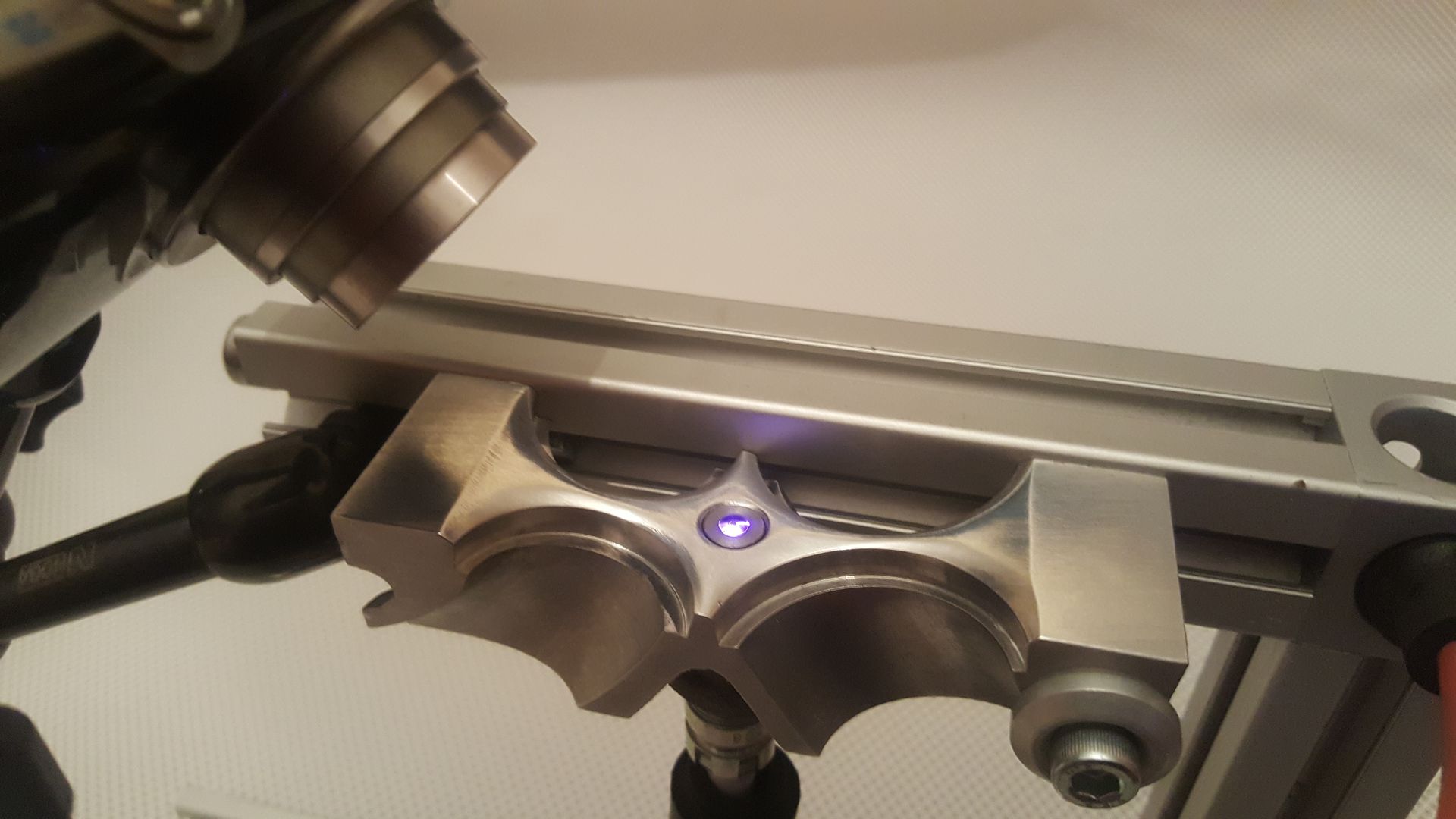

Onto the plug itself - the testing took place in a small fixture as shown below. The plug is mounted as normal in a section of F1 V10 Cylinder Head. The F1 Spark Plug is driven remotely from a Bosch "Coil on Plug" style spark plug driver. The coil is triggered with a micro controller which outputs a 5v logic signal to a Mosfet (transistor). A pull down resistor is fitted to the Mosfet in order to remove the 5v logic signal charge from the gate as quickly as possible when off. This makes switching at higher speeds possible. A suppressor diode was fitted across coil to protect the Mosfet on the load side.

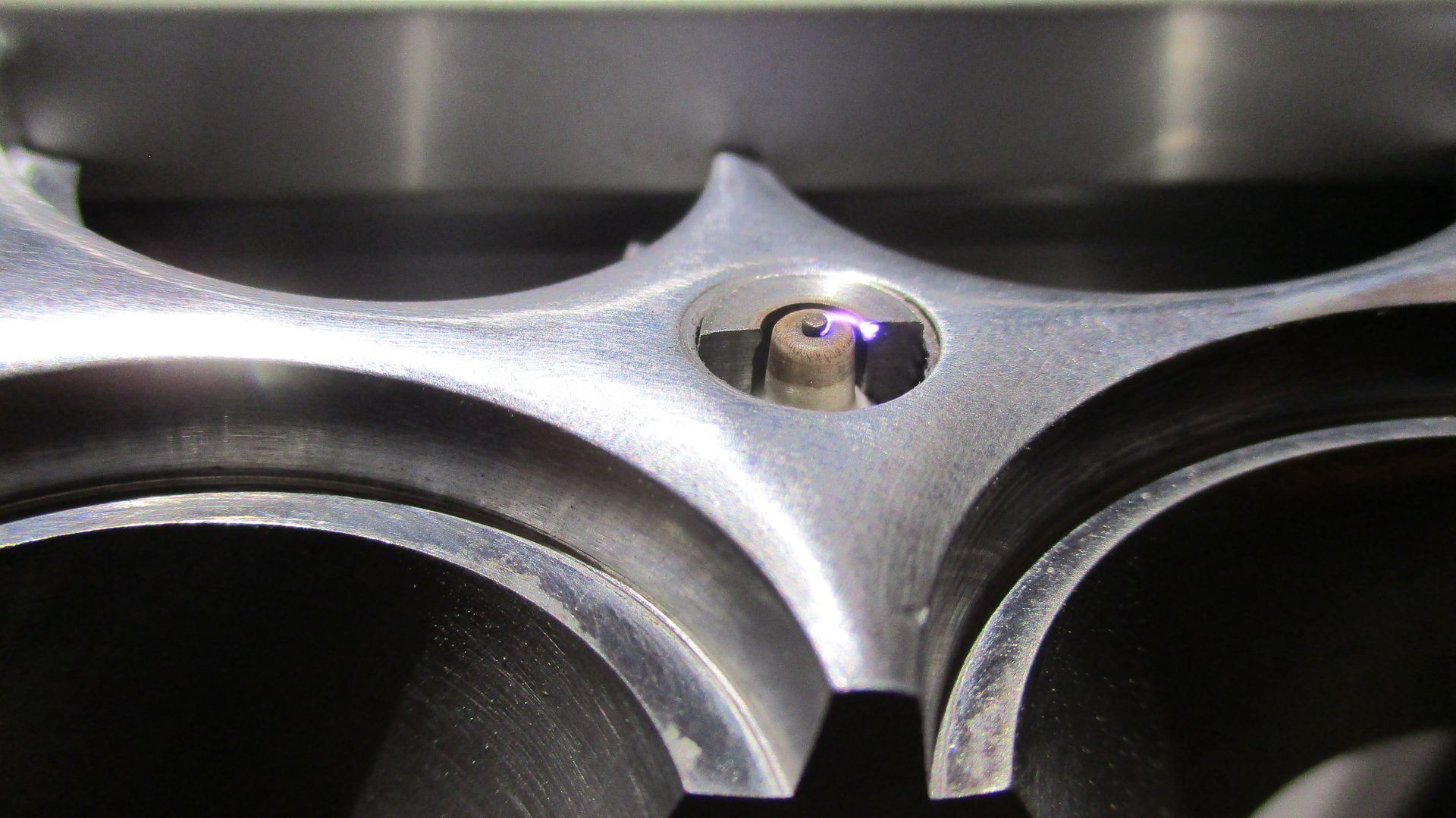

Coding the micro controller to allow various pulse frequencies was possible then - from the theoretical 8,900rpm idle all the way to the 19,000rpm red line. A separate logic signal from the micro controller was programmed into the code to fire ahead of the coil trigger signal. This separate signal was wired into a normal camera as shown below. This signal was timed to activate the camera at the same time as the spark was seen jumping the gap. Some shots were taken capturing multiple spark events for more vivid shots. It was the most basic and simplest way to capture spark events with parts I had on hand.

The rig shown below,

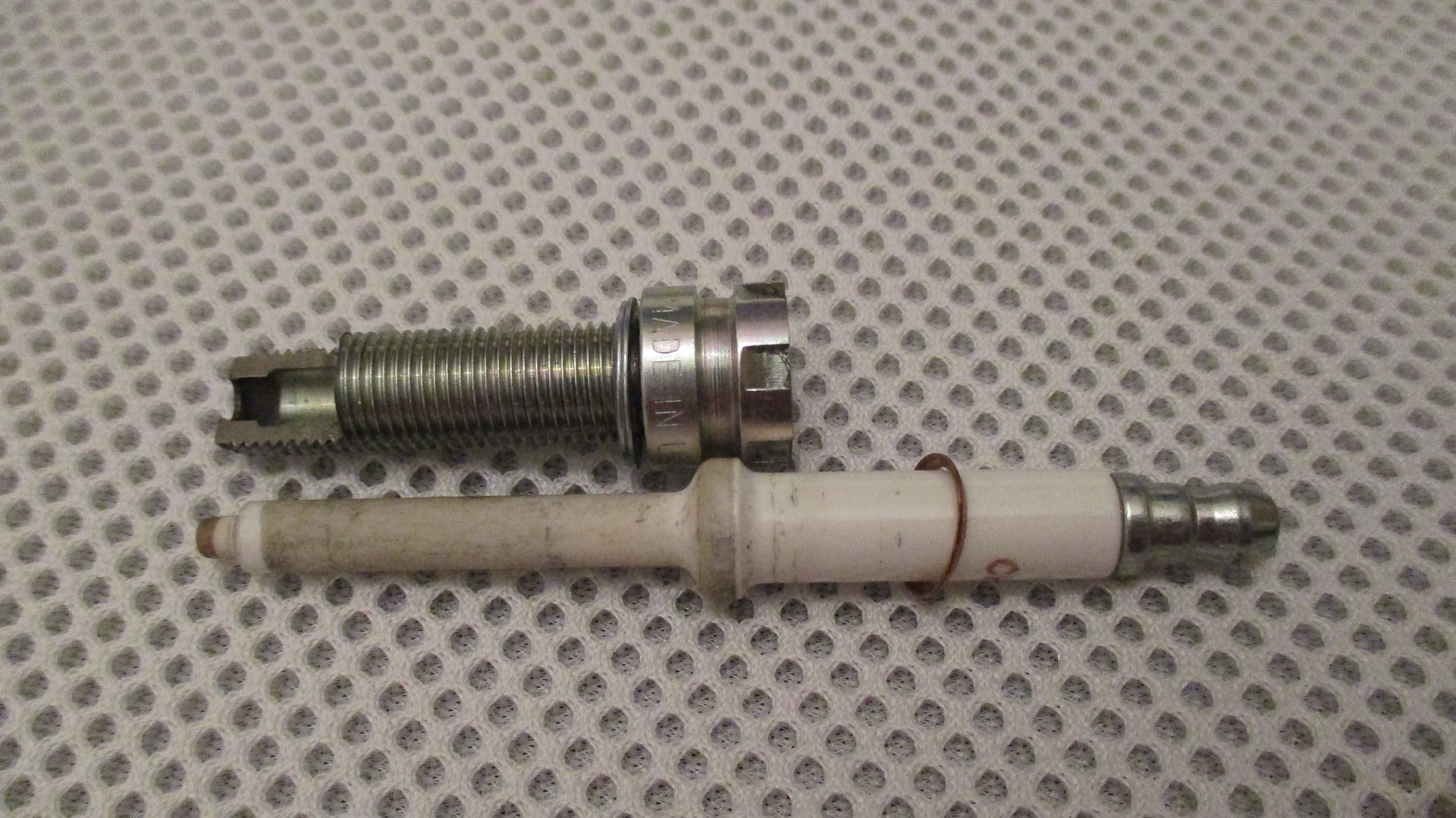

The F1 Spark Plug in question,

Approximate Dimensions,

Spark gap is 1.45mm - central electrode circumference to outer ground inner lip.

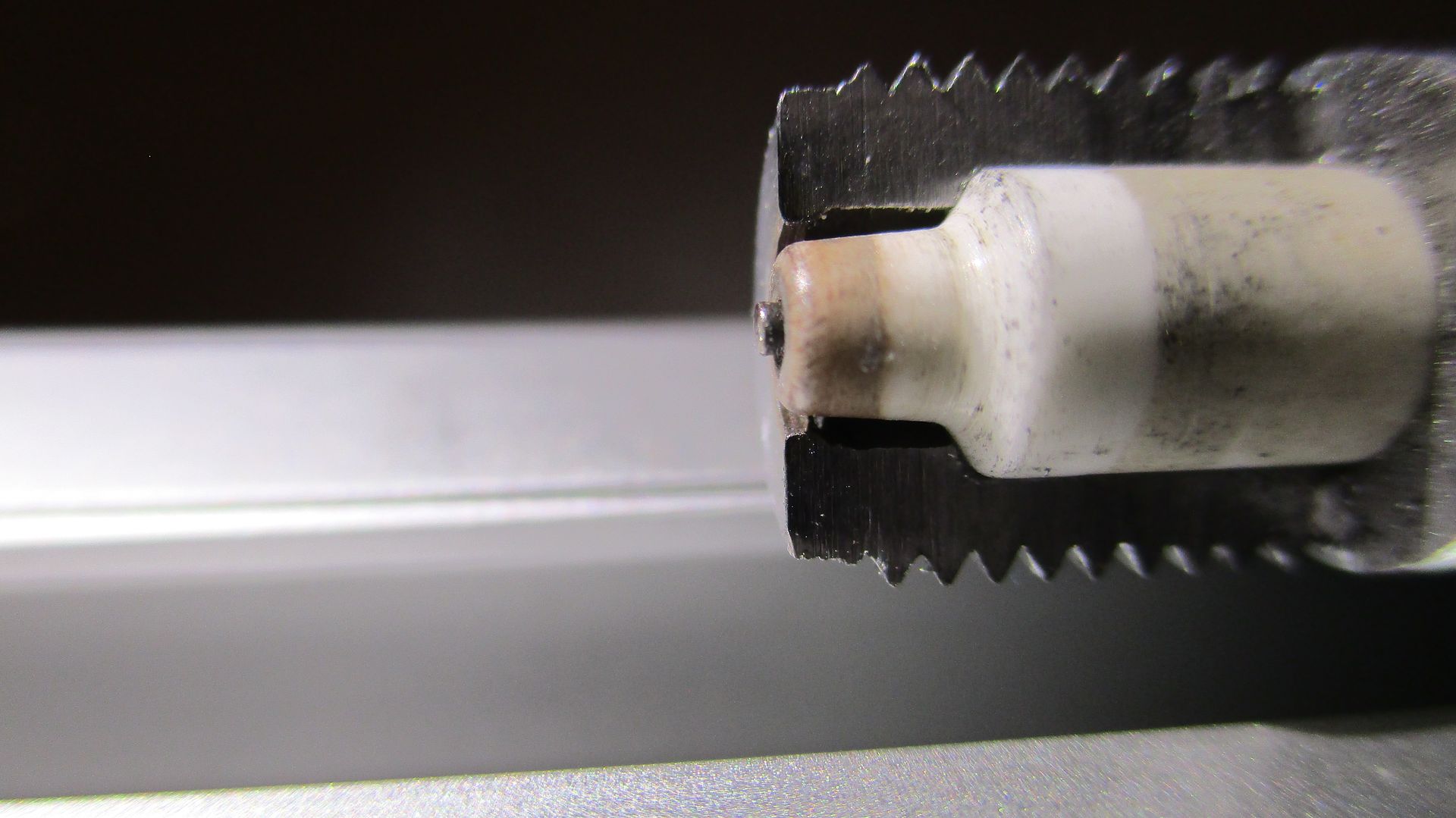

Because the plug fits deep inside the head in a tight fitting bore there is no room for the wall thickness of a conventional spark plug hex socket so a 6 prong tube spanner is used instead - this has the effect of being the same diameter as the plug body while also providing positive engagement. A similar shorter 4 prong tool shown below,

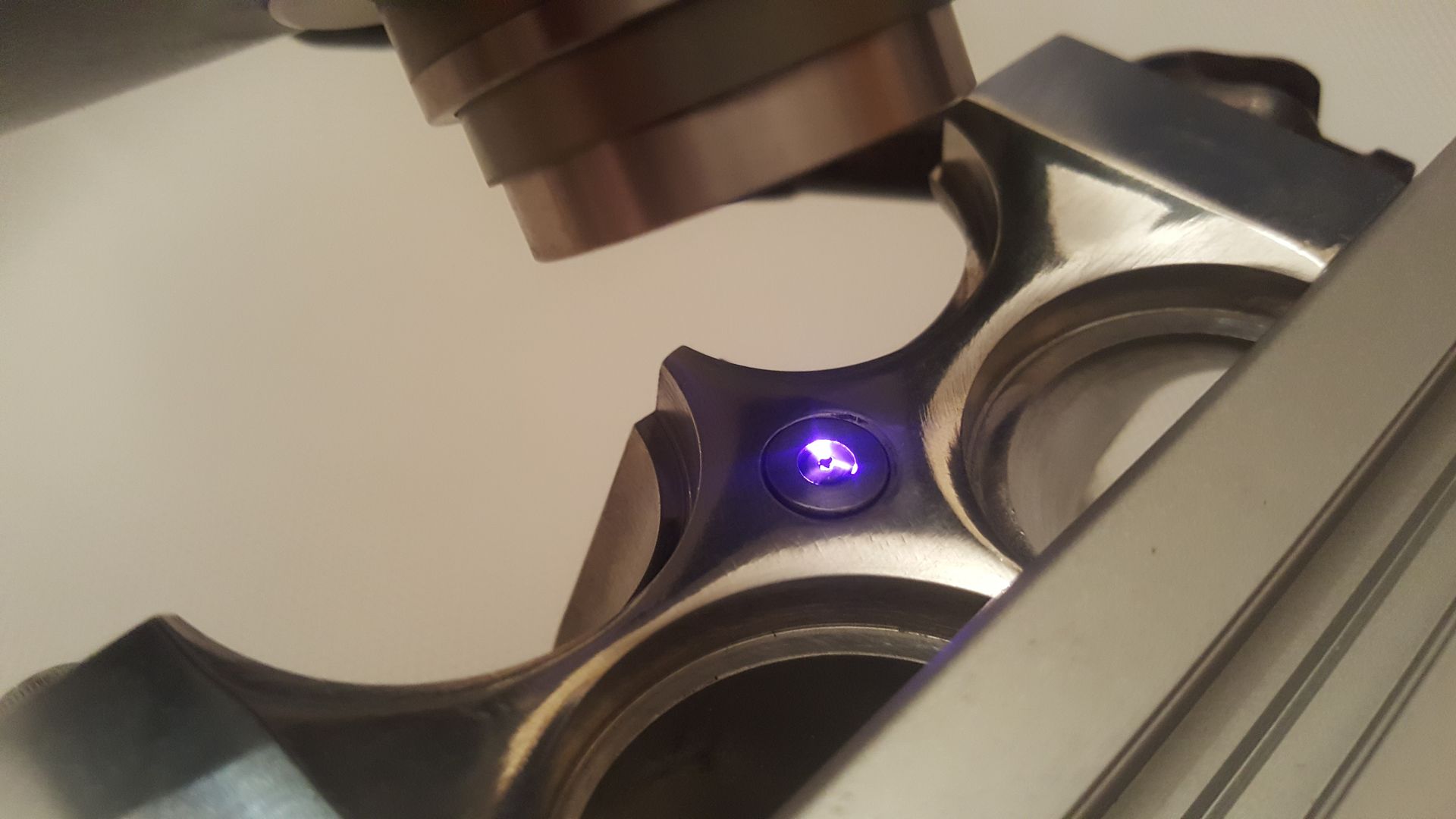

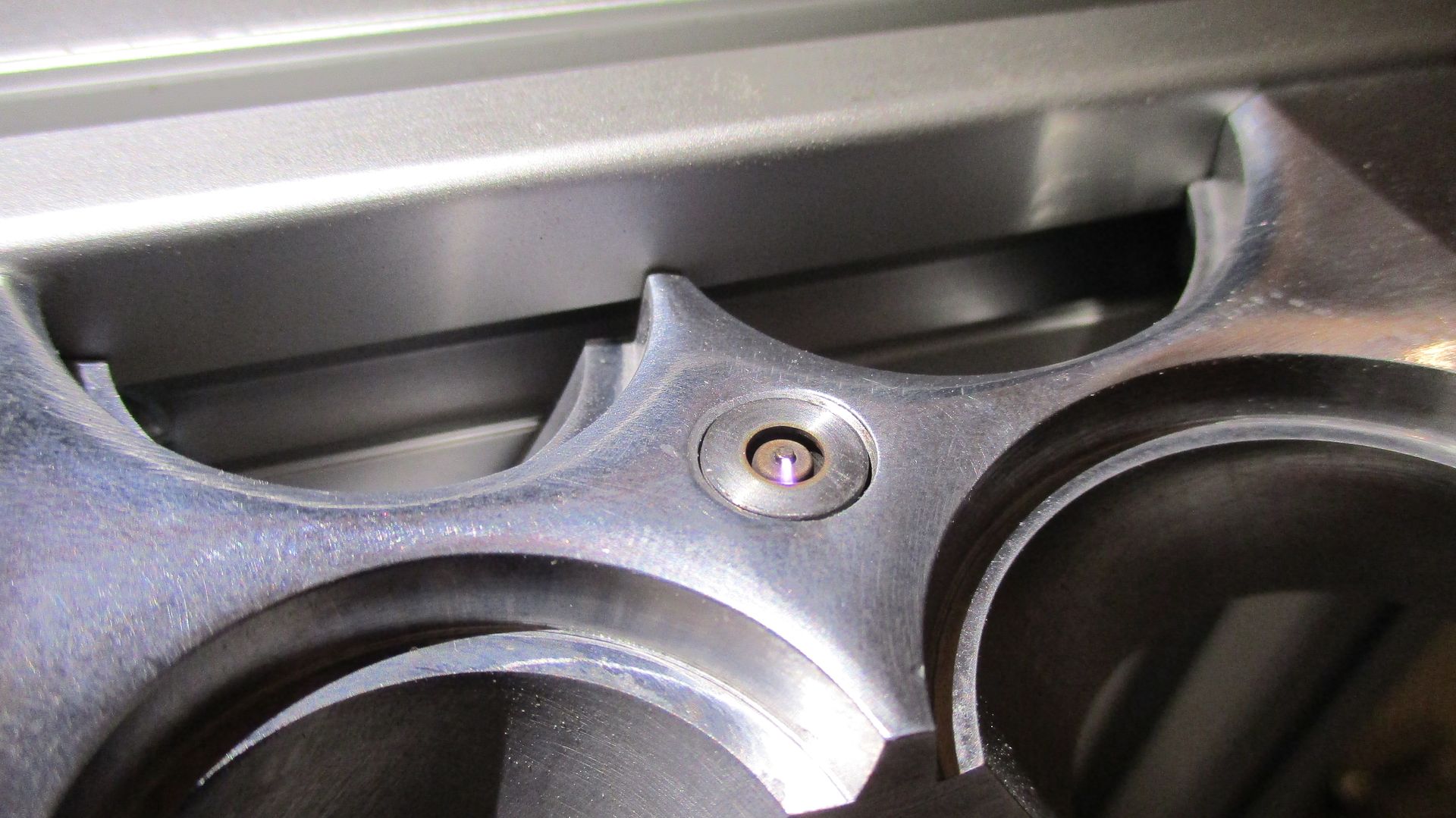

With the plug mounted the spark could be observed - notice below the ''Surface Gap'' compact design as mentioned above,

The system running,

Two photos using the coded camera trigger pulse as mentioned above, you will now notice the multiple spark capture spidering effect witnessed above has gone away,

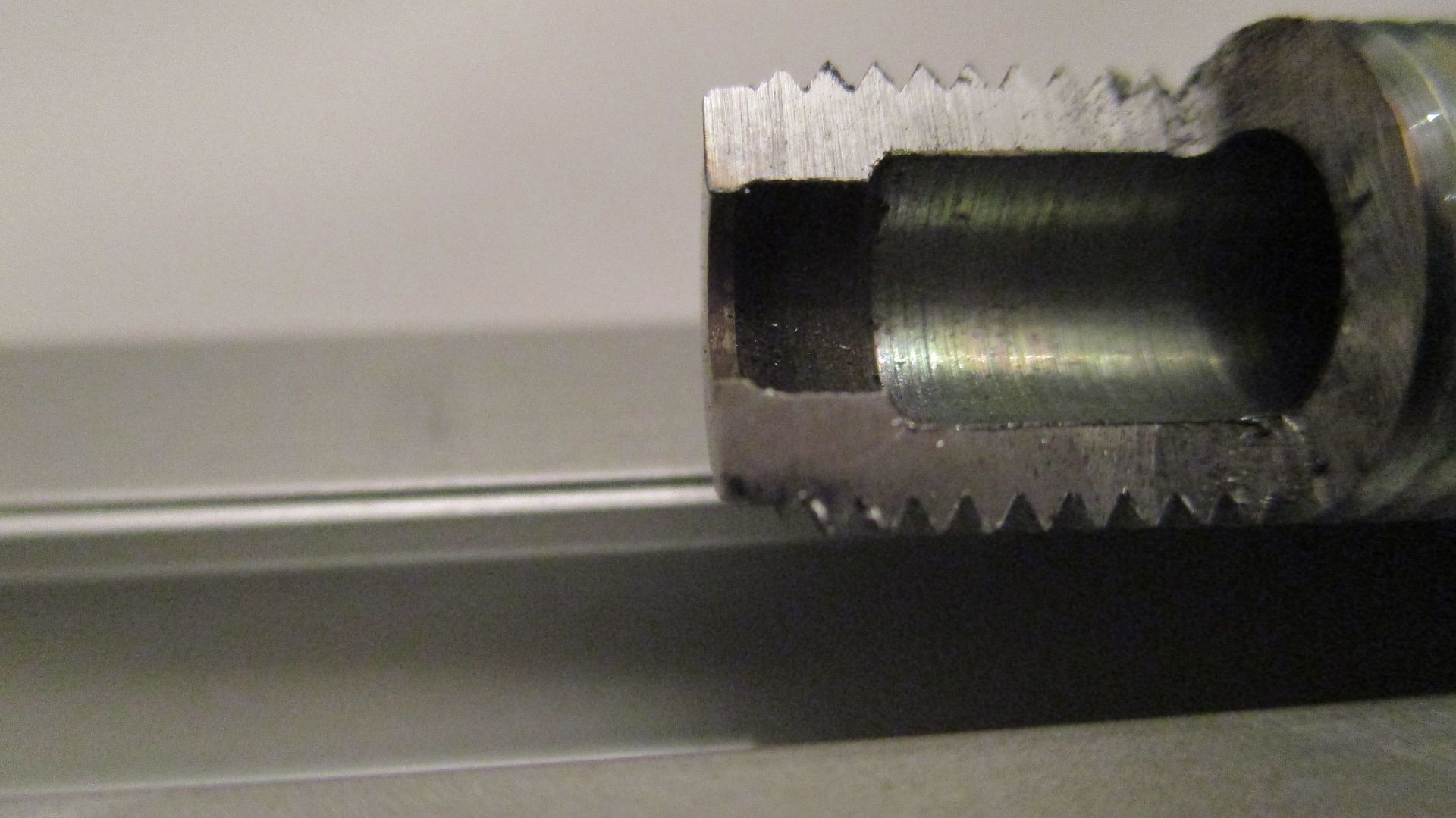

Removing the plug and machining a cutaway in the tip shows the face detail,

Back into the test rig and firing - jumping as designed to the inner concentric lip,

An overview of the again machined and opened plug - its construction no different from standard automotive plugs,

And lastly to finish, some standard automotive plugs contain internal ceramic resistors - used to suppress interference with a resistance value of approximately 5k Ohms. This is not the case with the F1 Spark Plug, and when checked shows no resistance from tip to tip.

Thats all for now, Enjoy!

Brian,