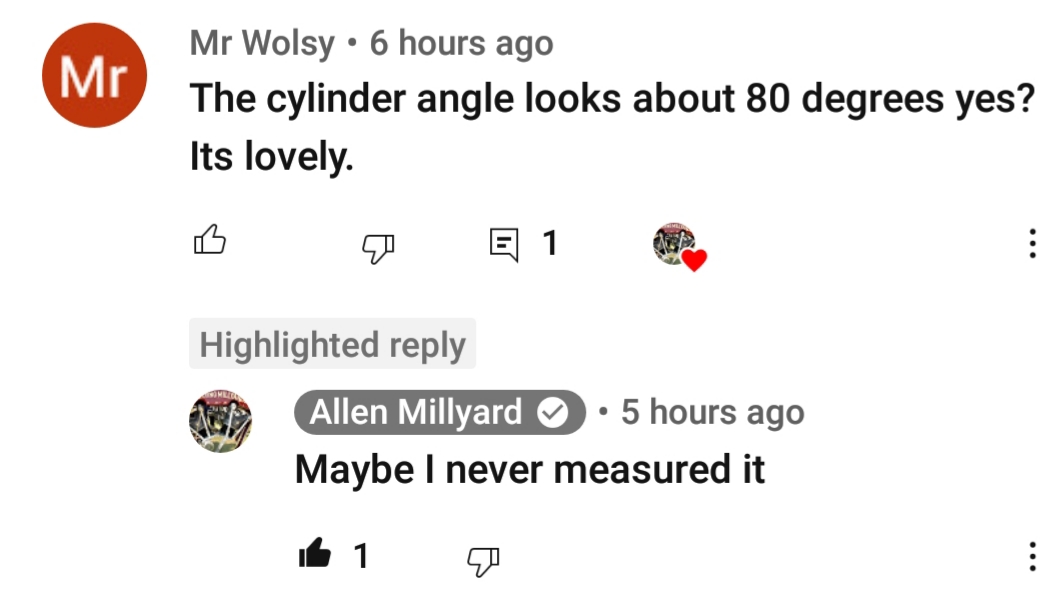

I know there are a lot of engine builders/designers who like to tinker around with engines on this forum. Has anyone ever designed or modified an engine that will rev to 18k to 20k RPM?

I know people have converted motorcycle engines before into V8's etc but has anyone build a specific 'replica' V8 or V10?

- Login or Register

No account yet? Sign up