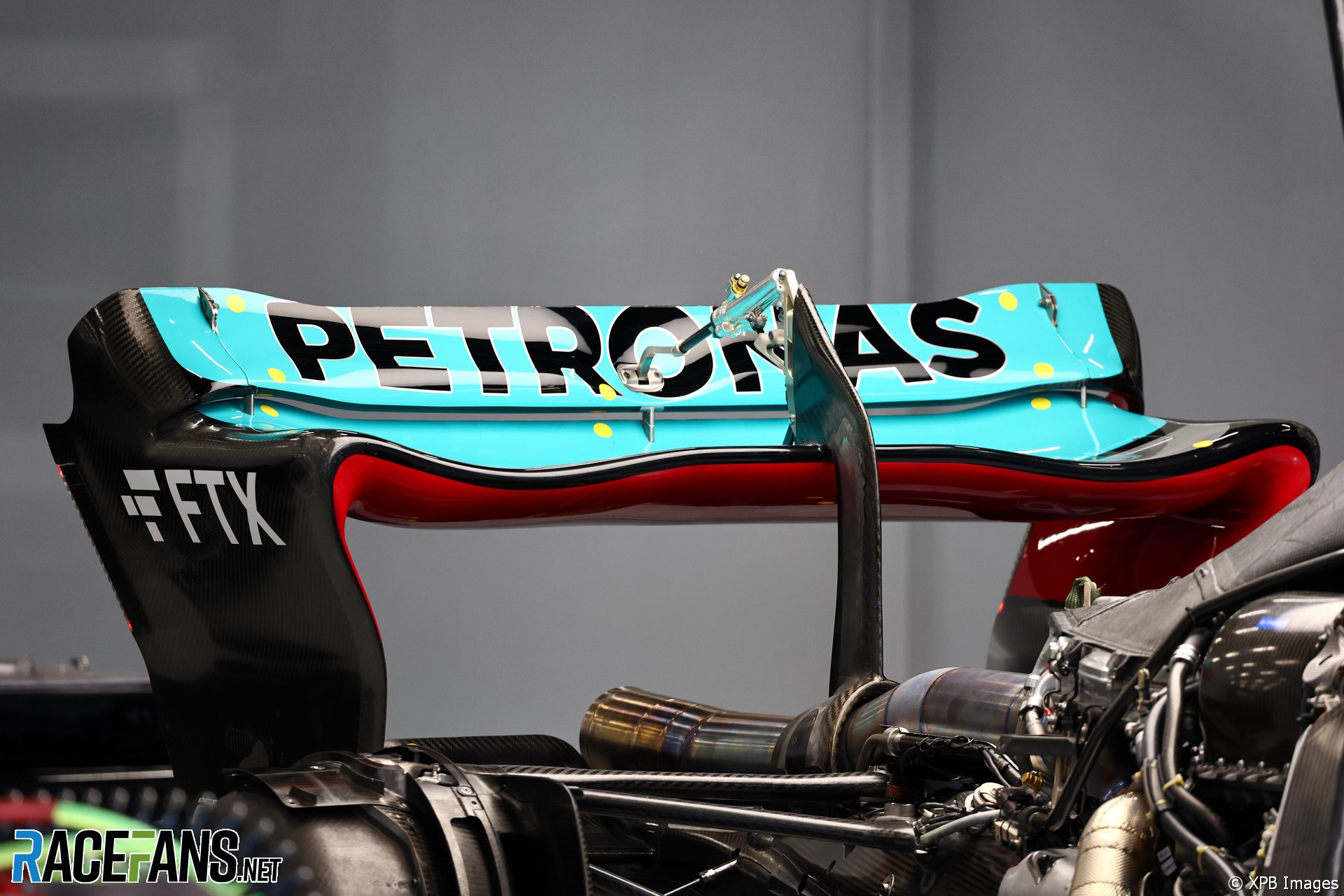

A photo for reference along with a crude MS Paint sketch of the assumed profile:

This photo from Australia shows the surface well (look at the curvature of the 'R', 'N' and 'A' on Petronas), and notice how this 'blister' tapers off along the Y-axis towards the DRS actuator mount and towards the end of its span where it meets the 'endplates'/DRS pivot pins.

And finally, on a slightly different topic, why is it common to see the pressure side of the main plane of a rear wing profile be cambered so much that it's concave?

And what I mean by that, is that if the force vector imparted by the pressure differential is normal to the surface it acts on, surely on a concave pressure surface this would then create a horizontal component which would form either drag or thrust?

Is this horizontal component so small relative to the vertical component that it can be disregarded as negligible? Likewise im guessing the majority of the force normal to the DRS flap is horizontal and therefore mainly drag force, but that is offset by the main benefit of having the slot in the first place to keep flow attached on the suction side for longer while having such aggressive trailing edge camber and flap AoA which is a net increase in downforce at the cost of it being much less efficient downforce that brings a lot of drag with it?

I also know the caveat that the suction side contributes more to downforce by a ratio of like 3-5:1 relative to the pressure side and of course, solutions seen in F1 aren't necessarily the most efficient or even the best with regards to peak downforce/drag reduction, it's just the best they can do within the confines of the regulations they have to work with (as well as time, budget, man power, manufacturing facility considerations), and of course, talking about the RW in a vacuum isn't ideal considering it's working as a system along with the beamwing and diffuser and is affected upstream by things like engine cover/intake, sidepods, floor space infront of rear wheels etc.