wesley123 wrote:so if the light colour is wear that means the floor is pulled up in some ay imho

look up my post...there is a substantial degree of freedom towards how precise you have to manufacture each and every surface vs the reference plane.

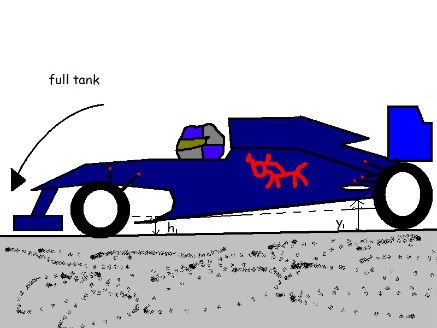

so in fact you can design a wedge ,a curve whatever is suited to prevent your plank to hit the ground in a ways that is not to your liking and claim it was just not possible for your outfit to achieve a better paralellism on grounds of your working precision..

the tolerance is a staggering +/-5mm to the reference plane!

the plank itself just has to be made from that a material with a specific density:

b) be made from an homogeneous material with a specific gravity between 1.3 and 1.45.

I personally do not understand why they use Jabroc...why not use something more resistant to abrasion?

the material is normally quoted as jabroc..

borrowed from the site below)

Jabroc® is a non-impregnated, densified wood laminate developed especially for a wide range of industrial applications. Selected beech veneers are kiln dried to a given moisture content, cut and assembled into packs with a film of synthetic resin coating the individual veneers. The packs are then subjected to extreme pressure and temperature, causing them to be bonded to form laminated boards.

By varying the laminating pressure and veneer grain direction in the pack assembly it is possible to produce material having various densities and strengths.

The material has been used in a wide range of applications over the years; Spitfire Propeller Blades, Underbody Skid Boards on racing cars, and Tooling in the Aerospace industry.

http://www.emisupply.com/catalog/jabroc-c-485.html