Hi newyorkkopter,newyorkkopter wrote: 747, I'm pressed to think of something that would do justice as an expression of gratitude; really useful finds, thanks again

I´m happy to help you, if I can - not much thanks needed.

I would be happy to see you start and later finishing your project, because

I´m sure, that you will learn many useful lessons along the way, and that it is

a good thing to do.

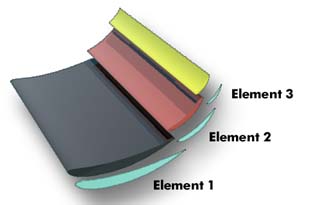

Here a photo, so that you can see how a F1 monocoque is built up.

You don´t need to really shap the core material (honeycomb).

It is used as sheets with different thickness for different parts of the monocoque.

For your model, I would not try to use honeycomb, as it will be very difficult to bond it propperly to the outer/inner carbon skin, if you don´t have pre-preg carbon cloth and a autoclave.

For your model, I would use a foam or balsa wood core, and try to get some vacuum baging. Please remember, that at the points, where you want/need to fix something to your monocoque ( e.g. where your suspension pick up points are, or where you connect your engine and nose cone), you will need aluminium hardpoints, so you will need to locate them when you layup your monocoque.

Good luck !!!! & have fun