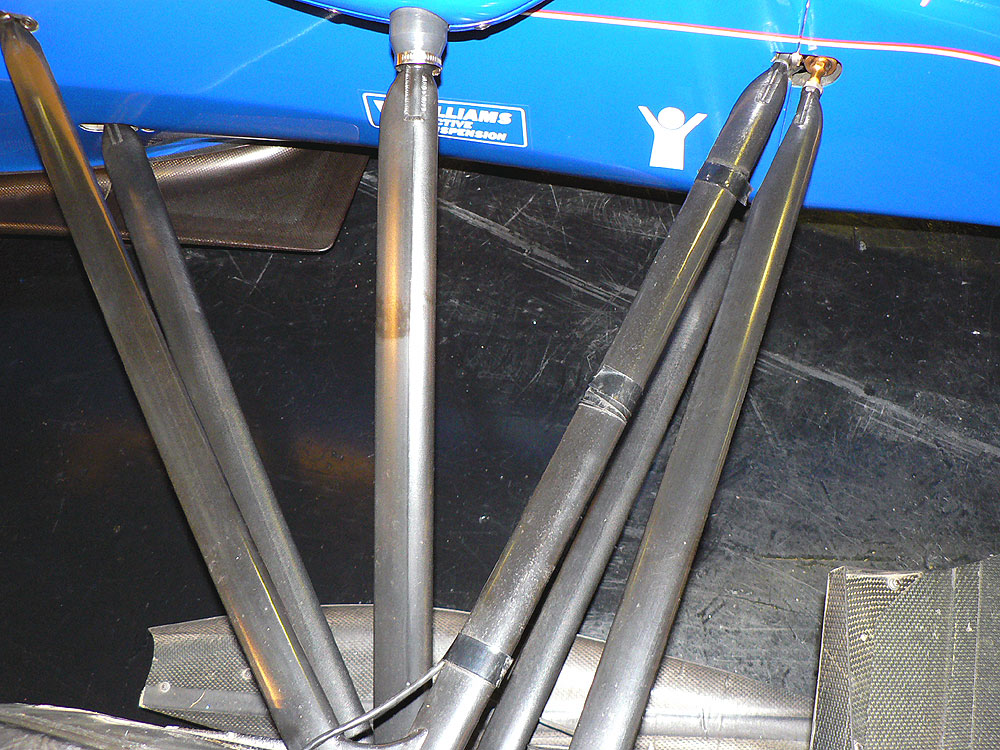

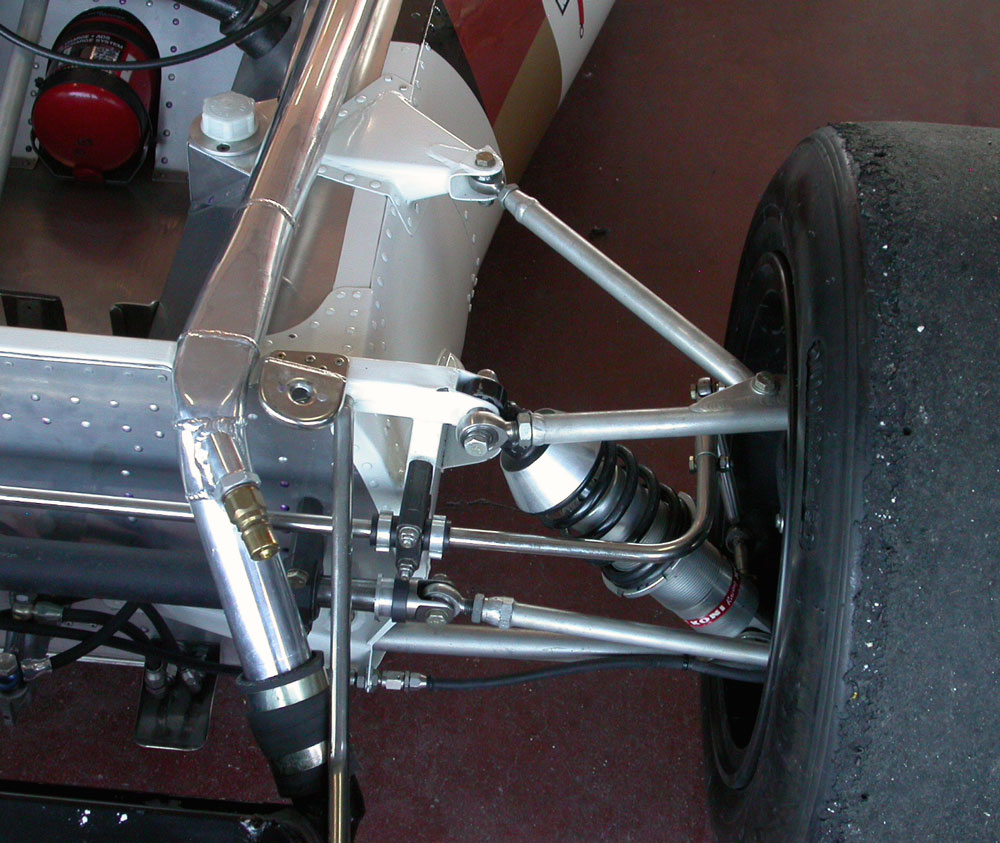

TIG welded CrMo alloy steel was used for A-arms, pushrods/pullrods, tie rods, and uprights in F1 up to the early 90's. CrMo is still used in Indy car suspensions per regulations. I believe Indy car requires steel suspension parts because the steel suspension parts tend to have a more benign structural failure mode than composite (bending rather than shattering) during an impact with an oval track wall.xpensive wrote:I don't think welded 4130 steel tubes, 25 CrMo 4 in my book, for suspension parts have been seen in F1 since the 70s, why I believe that machined Alu or Ti was the way to go before the carbon age. I can remember Gordon Murray already in the seventies xpressing his dislike for all sorts of welded components and John Barnard would probably have had a heart failure at the proposition.

The welded CrMo steel F1 uprights were beautiful examples of the race fabricator's hand craftsmanship. Except for headers and heat exchangers, we don't see too much of it on the cars anymore. But I will have to admit that the current generation 5-axis CNC machined monolithic aluminum uprights are also quite beautiful.