gilgen wrote:michl420 wrote:Everyone thinks it's a simply overheating problem, but that was never communicated. The visible problems are just small burn marks at the same point of both sidepods. And in this area is no cooler and normally no exhaust. So i would assume it is something electronic.

you are correct. it is not engine overheating that is the problem, but that heat radiated from the engine is frying the electronic controls and inverters that are located in a very small space. vents were created to try and keep these electronics cooler but didn't work. the units need to be positioned in a good airlflow. remember, even a 1o overheat can destroy electronics.

all that being said, the engine itself is causing problems, not in the mechanical workings, but in the electronic interface between the ers and the turbo. nothing to do with heat, but just incorrect programming.

10Kelvin is a lot ,but NOBODY would or could Position electronic parts somewhere a 10K too optimistic temperature would kill the component in 10minutes.

the logic here is 10K more in mean temperature is halving the lifetime of the component but there are some temperatures a component will simply be gone.so if your original design flirted with disaster anyways it is well possible a Little miscalculation on Peaks will burn capacitors ,melt pottings or introduce Tension inside components leading to sudden and early fail .

The engine compartment is not only an Environment of conductive and convective heat transfer you also see Radiant heat Transfer which might have a surprisingly big Impact from quite a distance- if a component does actually see the Emitter ...this may well be the case for Body Panels -but there are simple yet effective fixes to this -Teams resorting to putting wet towels on the sidepods to prevent blistering paint is the worst make do.

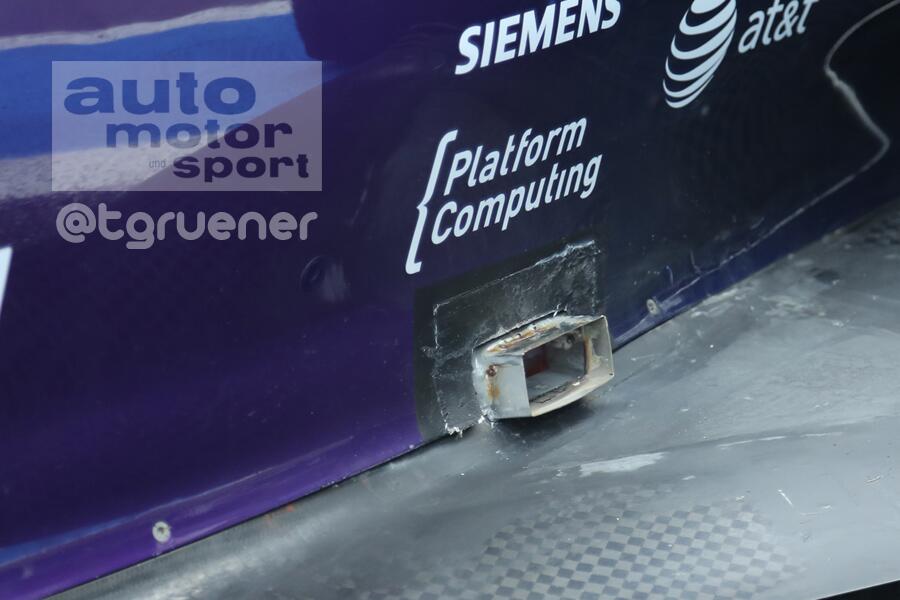

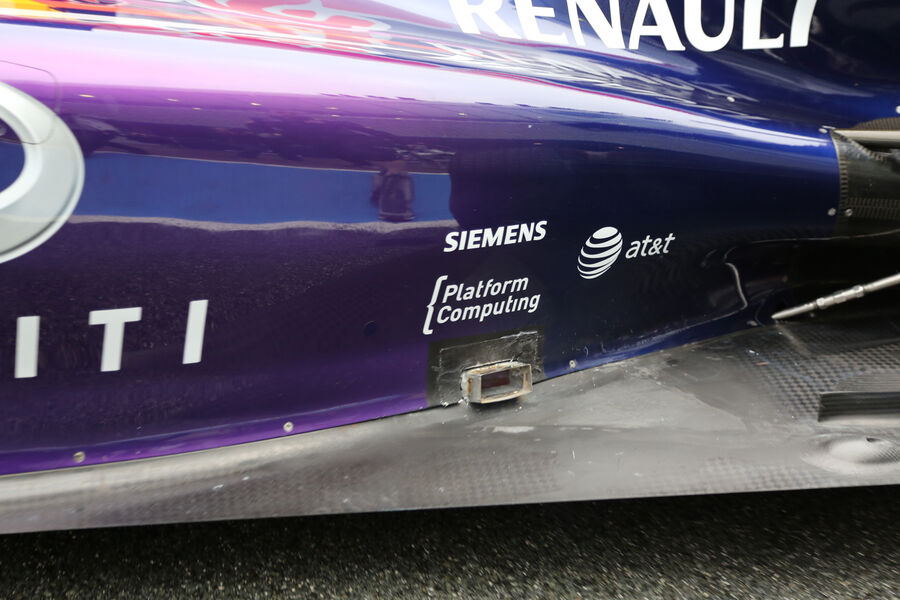

-looking at the Pictures above with the Joint line of sidepod and floor gaping in the areaof the fabricated duct it Looks like the floor has already had its dose of overheating ...-