yes no moving vehicle, the moving vehicle is 1/4 scale it will not have any human factor which means my concerns are less, the only thing that concerns me is to make the floor able to handle the wait of the engine and other components, a good thing is that i will be using aluminium for some parts which give some weight advantage,sgth0mas wrote:Yeah its incredibly tough to get information on it and in all honesty the fea programs for composites are in their infancy. Many companies have their own proprietary data that they will not share.

it looks like you are gong to have to use a linear isotropic solver...which will probably satisfy the academic requirement. But in practice it would not be sufficient. As long as this steering wheel isnt on a moving vehicle you probably have no major safety concerns. That would still be up to you to analyze.

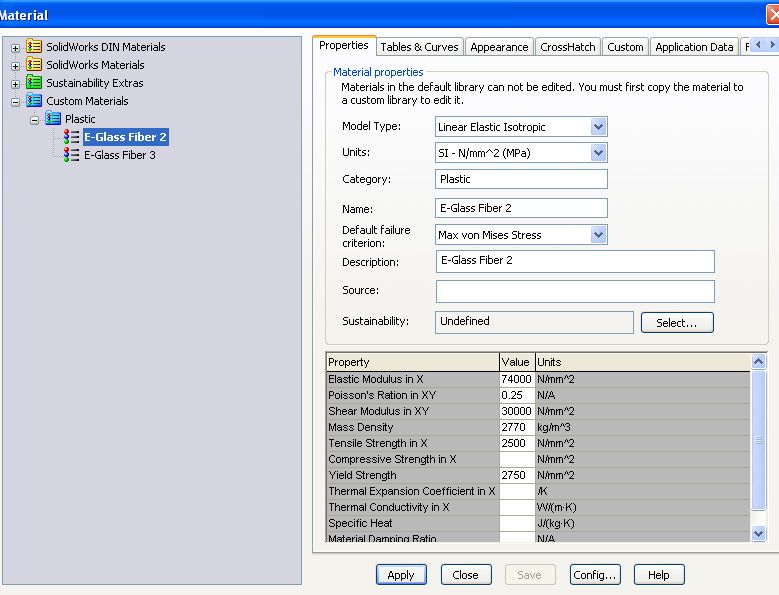

I looked at a few data sheets and it appears your CSM composite will probably be closer to 100 MPa yield strength. thats wayyyy lower than what you have, but still within the margin of your analysis. I dont remember the modulus. The values you are using now are at least 20x greater than what you can really expect from the composite.

As you gain more experience...you will realize there arent many how-to articles on what youre doing...so application of theories becomes paramount.

about the 100Mpa ! wow ! where did u get it, i mean the datasheet ?! because in all the sources i search on people were saying values from 2000Mpa to 2800 Mpa !!