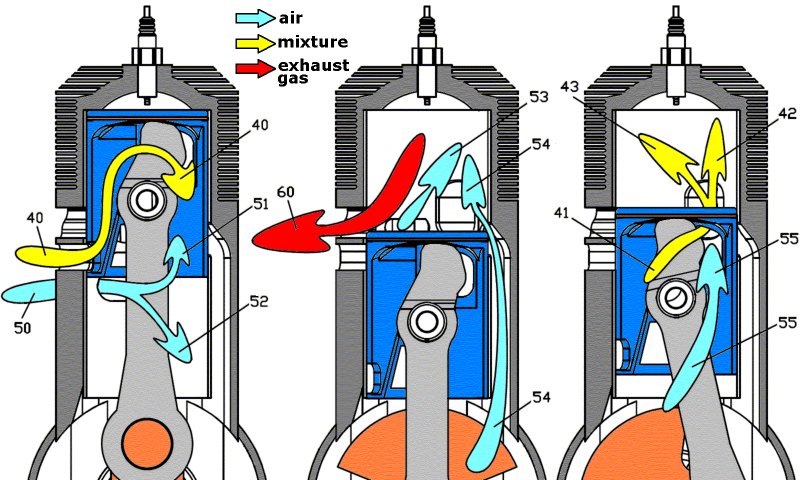

uniflow wrote: ↑26 May 2017, 12:44I see KTM have copied my Transfer Port Injection (TPI), same as the system I have shown here some time ago running on my YZ250 . Approx five years ago I had this system up and running with testing showing between 14 and 21% fuel savings over a standard YZ, same day, same track , same riders alternating bikes same top end power.This fuel burn has been tested again and again in the REAL world. It would seem KTM have seen my youtube and general postings on various forums, good on them, I'm glad someone has taken up the design and is using it, Im waiting on my free bike as payment. Same injector positioning aiming toward the incoming air in the B ports, same same. Actually I call it DTPI delayed transfer port injection as this is the trick. The fuel charge is delayed for a time before it is introduced into the air stream making it hard for the fuel to escape the cylinder ( runs out of time ) . Also the positioning of the injectors in the B ports helps stall short circuiting, off the pipe where short circuiting is worst.

As you would expect I have a mark two injection system that is BETTER than the original but it won't be shown here.

Twostrokes need a minimum of 40 to 1 oil at full throttle but under approx 60% torque they can be leaned out to 300 to 1 at idle.

The oil problem is a real problem for twostrokes but the raw hydrocarbons out the exhaust is the first big problem to overcome, this new system solves this problem (the mark two) . I have two oil less top ends on test here in my workshop, fourstroke bottom ends, also can't be show here. How ironic, looks like the twostroke is the future engine.

https://youtu.be/hOGZ5llowoU

https://youtu.be/1YG9ko8-Nwk

And the original TPI prototype first running in 2008, still running and entering events and no one is even aware of whats inside.

https://youtu.be/CnIemdISKrM

Good effort Uniflow, & ta for posting your achievements..

Early on in this thread you showed an interesting sleeve valve engine too.

I realize you have a lot on your plate, but any updates on this one to report?

For KTM to market the same basic set-up as pioneered by yourself Uniflow,

is quite kudos worthy, & interesting too, that your system was chosen over the

BMW developed DI unit that Husqvarna had 'ready to go' ~5 years ago, when KTM

took Husky over - from the BMW motorcycle division..